Showroom Location:Tanzania & Rwanda

Condition:New

Usage:Oil Press Machine Line

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:90%

Place of Origin:Henan, China

Brand Name:IN-HI

Voltage:380V

Dimension(L*W*H):1000X538X1050mm

Weight:140 KG

Warranty:1 Year, Video technical and Online support, Field maintenance repair service

Key Selling Points:Easy to Operate

Marketing Type:Hot Product 2019

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Other, Gear, Bearing, Engine, Gearbox

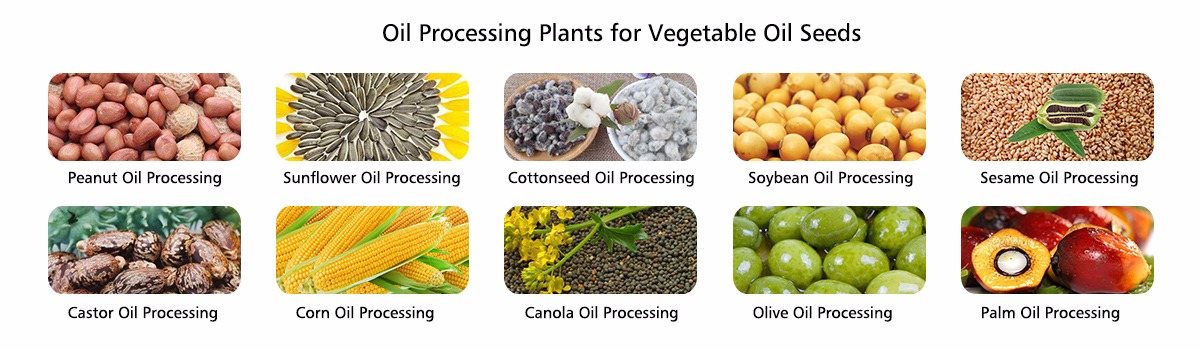

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, SESAME OIL, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

Max Capacity:62.5kg/h

Product name:New Food Oil Make Machine, Industrial Cocunut Oil Making Machinery

MOQ:1 Set

key words:industrial cocunut oil making machine

Raw material:Oil Seeds

Advantage:Simple Operation

Certification:ISO/CE

Item:new model food oil make machine

After-sales Service:Field installation, commissioning and training, online support

Delivery:15 Working Days

6YL-68 New Model Food Oil Make Machine, Industrial Cocunut Oil Making Machinery

Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm seeds and jatropha seeds.

Raw material

Hot and cold automatic modern oil press is a new product developed by our company. It can press rapeseed, peanuts, tea seed, soybean, sesame, sunflower and other oilseeds, the machine is equipped with micro electric control, infrared heating, filtration system, multistage press.

Working priciple

Working priciple

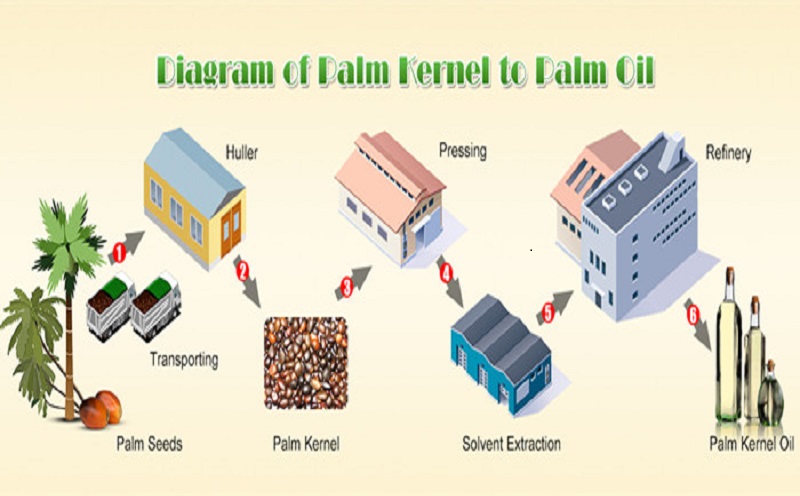

Flow Chart of Small scale edible oil refinery plant coconut oil processing machine production line:Crude Oil→ Filter→ Degumming→ Deacidification→ Decoloring→ Deodorizing→ Dewaxing→ Defeat→ First Grade Oil

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Project name | capacity | suitable for raw material |

| oil pressing production line | 10–800t/d | sunflower seed, soybean, peanut, sesame, corn germ, tea seed, rapeseed, cottonseed, etc |

| oil solvent-extracting production line | 30–800t/d | pressed oil cake, soybean flakes, rice bran pallet, etc. |

| oil refining production line | 3–500t/d | all kinds of vegetable oil |

| palm oil mill production line | 5t/h–90t/h | palm fruit bunch |

| oil fractionation production line | 20–500t/d | refined palm oil |

| Oilseeds protein, phospholipids | 50–500t/d | soybean meal, etc. |

| grain deep processing line | 20–1000t/d | corn, wheat, beans, etc. |

Company Profile

We are a reputed manufacturer and joint-stock enterprise with import & export rights andmainlyproduces oil press machinery and othersl equipment.Moreover, superior after-sales services guarantee highqualitycontinuously. In addition, we have a group of experienced and excellent after-sales service members who provide following up services for worldwide customers.Customers’ need is what we are trying to create. Customer satisfaction is what we are seeking. Over the last couple of decades, Benteng people have created continuously, transcending ourselves and insisting on the conceptof”Development is of overriding importance”. Develop the brand with quality. Promote the brand with service. We, Benteng people,areforging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Service

Ensure the quality100% test before delivery All products undergo strict product quality testing before packing.Customized serviceWe are an industry and trade integrated company, has its own production workshop has its own research team. Provide personalizedcustomization service.Rich experienceMore than 30 years independent research and development, independent production experience. Excellent customer service andtechnical support.

FAQ

1.Q:Can you guarantee the quality of your machine?A:We are a professional manufacturer with strict quality requirementsoil press machine2.Q:Does your factory accept customization?A:As a professional manufacturer, we can do almost any kind of customization.3.Q:What’s the delivery time?A:Generally after paying the final payment 3-5 days.4.Q:How long can I receive the goods after placing the order?A:7-15 days if there is no unexpected.5.Q:What should I do if the oil making machine will not be installed?A:Don’t worry, we have a perfect after-sales service system and can provide you video supports for free.6.Q:What’s your terms of payment?A:50% in advance, balance before shipment.