Applicable Industries:Hotels, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Other

Showroom Location:United States

Condition:New

Application:Food, Chemical

Packaging Type:CANS, Bottles

Packaging Material:Plastic, Wood

Automatic Grade:Semi-automatic

Driven Type:Electric

Voltage:220V, 110v,

Place of Origin:Henan, China

Brand Name:Multi-sweet

Dimension(L*W*H):1pc/carton 41*41*26cm

Weight:10 KG

Warranty:1 Year

Key Selling Points:low noise and high efficiency

Machinery Capacity:4000BPH

Filling Material:Beer, Other, Milk, Water, Oil, Juice, Honey

Filling Accuracy:up and down 2%

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, Engine

Product name:bottle filling machine

Material:Stainless steel

With pump:Yes

Customize serviec:Accept

Filling range and speed:Can be adjusted

Advantage:low noise and high efficiency

Usage1:machine fill honey

Usage2:Oil honey filling

Usage:paste filling machine

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Australia

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE

Automatic Cream Oil honey filling Machine paste bottle filling machine

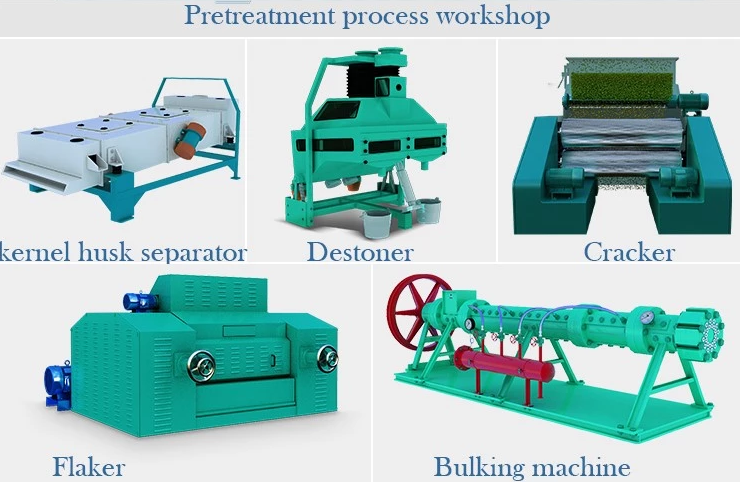

Automatic oil machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

Our machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

Pre-Sales Service* Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

Product Specification

Product Specification

| model | Capacity (kg/h) |

Voltage (V) |

Vacuum power | Power (kw) |

Squeeze speed | Weight (kg) |

Dimension (mm) |

| 6YL-70 | hot:60kg | 380v | 0.75kw | 4kw | 600-100BRM | 440kg | 1400*1000*1500 |

| 6YL-85 | 100kg | 380v | 1.1kw | 11kw | 600-100BRM | 550kg | 1600*1100*1600 |

| 6YL-100 | cold:75kg hot:180kg | 380v | 1.1kw | 11kw | 600-100BRM | 1200kg | 2100*1500*1800 |

| 6YL-108 | 200kg | 380v | 1.1kw | 11kw | 600-100BRM | 1400kg | 2200*1500*1800 |

| 6YL-118 | 230kg | 380v | 1.1kw | 11kw | 600-100BRM | 1500kg | 2300*1500*1800 |

| 6YL-128 | cold:150kg hot:300kg | 380v | 1.1kw | 15kw | 600-100BRM | 1750kg | 2500*1500*1800 |

Company Profile

We are a professional oil and grain processing and refining equipment manufacturer in China, which is specialized in the research, design and manufacture of high quality equipment for making edible oils and other auxiliary products.Our company has engineer with more than 30 years of experience in the oil and grain industry and refining and fractionation industry. They are in charge of designing the machines, arranging the product line layouts, installing and adjusting equipment, training staff and working out the best formula for each client.

Service

Pre-sale services1) Selecting equipment type;2) Designing and fabricating the products in accordance with the special requirements of the clients;3) Training technical personnel for our clients;4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.After-sale services1) Assisting the clients preparing for the first construction scheme;2) Installing and testing the equipment;3) Training the first-line operators on site;4)Supplying spare parts with cost.

FAQ

Q:Are you manufacturer?A:Yes,we are manufacturer with more than 20 year’experience.Q:Can you ship the machine to my address?A:Yes,we could use DHL to delivery the machine while the transport cost will be not cheap.And it is suitable for this kind of machine.Q:Where are you?Can we go to China and visit your factory?A:Yes,of course.We are in Henan,China.Welcome to our factory.Q:Do you have manual with the machine?A:Yes,of course.It is in English version.Q:Can you offer us the necessary paper to do the customs clearance?A:Yes,of course.We will send you the commercial invoice,sales contract,packing list,bill of lading(FOB or CFR,CIF terms),insurance policy(if CIF terms),also CO if you need.