Showroom Location:South Korea

Condition:New

Usage:OLIVE OIL

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:98%-100%

Place of Origin:Henan, China

Brand Name:qifeng

Voltage:380V/50HZ

Dimension(L*W*H):2300*1000*1600mm

Weight:1200kg

Warranty:1 Year

Key Selling Points:Automatic

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL, Palm Oil

Max Capacity:300 kg/h

After-sales Service Provided:Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Raw material:olive fruit

Application:olive oil extraction

Material:Stainless Steel SS304/316

Color:Customers’ Request

Function:multip purpose

Advantage:High Oil Yield

advantage:long service life

warranty period:12month

Feature:Energy Consumption

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Malaysia

Certification:CE ISO

refined & cold oil press machine with topmust quality & cheap price

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Raw material

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Working priciple

Working priciple

vegetable oil processing plant/oil extracting machine/oil refinery machinepretreatment/pre-press equipment.

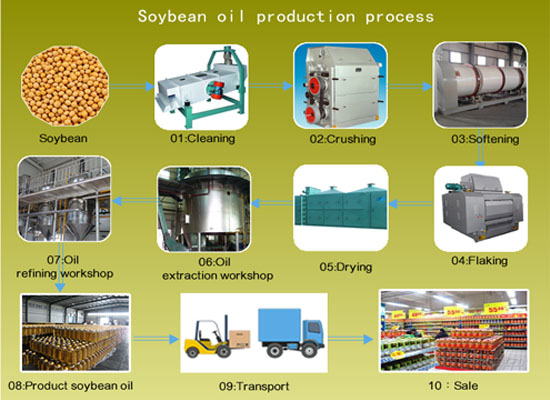

Elevator- shelling – elevator – cleaning -elevator – magnetic drum – flaking- elevator -cooking – pre-press- to extraction work

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Usage | sunflower oil production line |

| Type | Cold & Hot Pressing Machine |

| Automatic Grade | Automatic |

| Place of Origin | China |

| Voltage | 220V/380V/440V |

| Oil type | Sunflower Seed Oil |

| Max Capacity | 3000tpd |

| Product name | Vegetable Oil Sunflower Cooking Oil Production Line Of Edible Oil |

| Raw material | Sunflower seeds |

| Factory visit | welcome |

Company Profile

We are a professional manufacturer and exporter of mechanical equipment. Our products include edible oil process machines.Our well-equipped facilities,complete after-sale service system and excellent quality control system on all stages of production enable us to satisfy customers from different countries. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.