Condition:New

Automatic Grade:Full auto, Automatic

Driven Type:Electric, Electric

Voltage:220/380V

Place of Origin:Guangdong, China

Year:2020

Brand Name:Mingyue

Dimension(L*W*H):2000*970*2100mm

Warranty:1 Year

Key Selling Points:Easy to Operate

Marketing Type:New Product 2020

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:6 months

Core Components:Motor, Pump, PLC

Applicable Industries:Hotels, Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Food & Beverage Shops

Showroom Location:None

Type:Filling Machine

Application:Pharmaceutical

Packaging Type:Bottles

Packaging Material:metal

After-sales Service Provided:Online support, Video technical support

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None,attrValueId:3270618

Hot Selling Running Stable Honey Jar Hand Sanitizer Detergent Olive Oil Liquid Filling Line With Fast Delivery

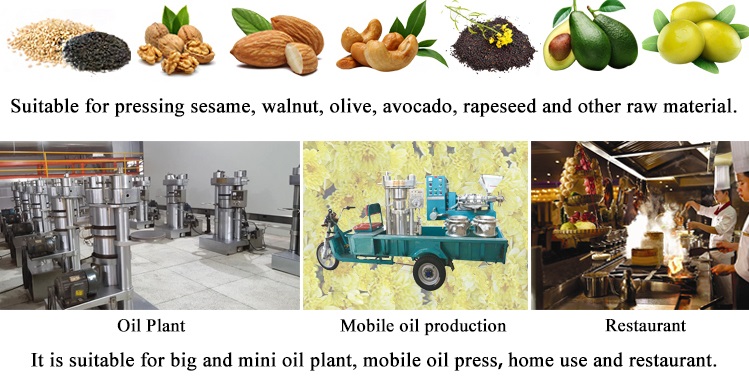

various raw materials, as ground nuts, bean, rape and cotton seeds, sesame, olive, sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

Raw material

Processing materials: sunflower seed, peanut, mustard, almond, black sesame, tea seed, cottonseed, etc

Working priciple

Working priciple

Palm oil is divided into red oil and white oil. Red oil is pressed by the palm fruit pulp, mainly for edible oil. White oil is pressed by the palm kernel, mainly for industrial oil. Red oil is made by the fresh palm fruit string, each string is 10Kg to 20Kg. The fruit string should do the high temperature cooking, Threshing the fruit for the string, heating and pressed by our palm oil press can get red oil with water and stag, with separting and filting get red palm oil

Advantage

High oil yield – The oil yield can be improve 2 to 3 percentage points than older equipment.Energy saving – With same output reduces electricity power by 40%.Labor saving – With same output can save 60% of labor, and 1 to 2 people can organize production.Pure oil – Vacuum filtration residue to ensure the purity of oil, in line with health and quarantine standards.Small footprint – 10-20 square meters to meet the needs.Precision manufacturing – High alloy carbon steel, high frequency quenching and heat treatment, which improves the service life of the oil press.

Product Specification

Product Specification

| Model | 6YL-60 | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-160 | |

| Dia. | Φ53mm | Φ81mm | φ101mm | φ123mm | φ160mm | |

| Screw speed | 64 r/min | 47r/min | 38r/min | 35r/min | 32r/min | |

| Power | Motor | 1.5-2.2kw | 5.5kw | 7.5kw | 11kw | 22kw |

| Vacuum pump | 0.18kw(VP-1.5) | 0.55kw | 0.75kw | 1.1kw | 1.1kw | |

| Heater | 0.9kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | |

| Capacity | 4.-60kg/h | 80-100kg/h | 150-200kg/h | 250-300kg/h | 500-600kg/h | |

| Weight | 268kg | 880kg | 1250kg | 1500kg | 1800kg | |

| Size(mm) | 1020*720*798 | 1500*1200*1750 | 2000*1300*1850 | 2100*1300*1850 | 2300*1300*1950 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.In recent years, the company has completed hundreds of projects involving oil pre-pressing, extraction, oil refining, animal oil refinery processing, small species of oil refining and biodiesel, a project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery, 100t / d of biodiesel and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Pre-Sales Service* professional sales team.* 24 hours online service.* visit our Factory.After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

FAQ

1.Q: How about the after service?A: We have a strong team, special for after service. We can arrange engineers to do service for you. And we insist “Quality is Life”.2.Q: Are you factory or trading company? Where is your factory located?A: We are a factory in machine development; Our factory is located in Zhengzhou Henan Province, welcome you come to China and have a visit.3.Q: Do you have English install step or vedio ?A: Sure, we have.Will send it to you when you need it.4.Q: How does your factory do regarding quality control?A: Quality is priority. We always attach great importance to quality controlling from the beginning.5.Q: why choose Our Machinery?A: We are one of leader in this field(in China). Our quality products and servicehave enabled us to expand our market from china to more than 60 countries.6. Q: How long will you send the machine after I pay?A: Normally, about 5-7 days. Also, if urgent, pls contact with us.7. Q: How can I pay?A: By T/T(wire transfer),Western Union, Money Gram, Alibaba Trade Assurance.Pls feel free to contact us if you want get more information or any question ! !