Brand Name:Ispuring Or OEM

Model Number:IP-606

Non-Stick Material:PTFE

Shape:Round

Voltage (V):220

After-sales Service Provided:Free spare parts

Warranty:1 Year

Capacity:5.1-6L

Application:Hotel, Household

Power Source:Electric

App-Controlled:Yes

Product name:Air Fryer

Multi function:Broil, Grills, Roasts, Oil-free Fry,etc

Usage:Frying Food

Packing Size:35.5*35.5*42cm

Certification:CB/CE/EMC/GS/LFGB

Material:Aluminum

Type:Digital Air Fryer

Function:Adjustable Thermostat Control, LCD Display, Non-Stick Cooking Surface

Controlling Mode:Manual Control / Mechanic Timer

Power (W):1500

Oil Capacity:3.6L

Multifunctional Deep Hot Digital Air Fryer No Oil Machine

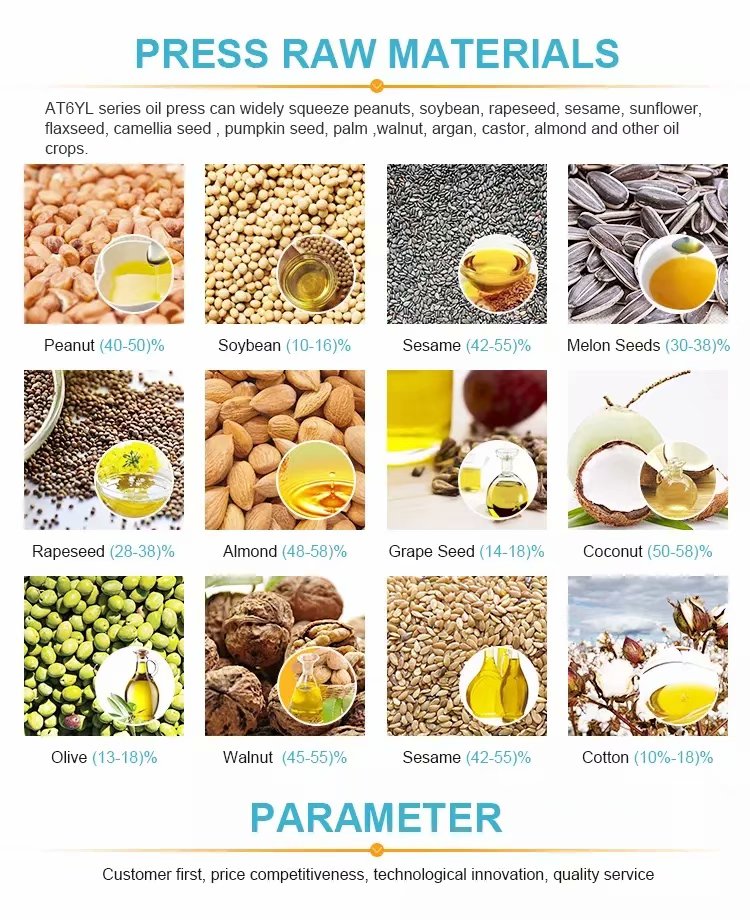

All kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more.

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1. High oil rate – Compared with the old equipment, the normal rate of oil can be higher than 2-3 percentage points, the annual economic benefits are considerable.2. Energy saving – The same output reduces electric power by 40%.3. Labor savings – Equal production saves labor by 60%, and production can be organized by 1-2 persons.4.Tuses high carbon steel, which through high frequency quenching and heat-resisting, it is high hardness and strength, good abrasion resistance that suit for high temperature and high pressure continous working, all this had improved the service life of the oil press for decades.5.For the gear-box’s gears,adopt the special helical&couping fear’s design and low noise,long working life.6.Final oil is high quality, good smell, and high yield rate.7. Wide use – It can squeeze peanuts, flax, sesame, rapeseed, sunflower, cottonseed, soybeans and more than 30 kinds of oil crops.8. Small footprint – It takes 10-20 square meters to be used.

Product Specification

Product Specification

| item | value |

| Voltage | 380V |

| Dimension(L*W*H) | 1200x550x1050mm |

| Weight | 130KG |

| Max Capacity | 500 kg/h |

| Product name | Oli Press Machine |

| Raw material | Palm Fruit |

| Function | Press Oil Seeds |

| Application | Edible Oil Production |

| Advantage | Energy Saving |

| Keyword | Small Capacity Oil Press Machine |

| Material | 304 Stainless Steel |

Company Profile

We are one leading producer of oil equipment in China. We are specialized in vegetable oil production line for 40 years. Our company have special engineers for cooking oil making machine. They are reseaching and developing the technology.We have advanced processing vegetable oil production line and scientific management system. The vegetable oil production line have gained many achievements and awards. Our machines have been exported to Congo, Urganda, Uzbekistan, Kazakhstan, Cananda, Chile, Argentina, Ethiopia, Zambia, Nigeria, Russia, Turkey and so on.

Service

Pre-Sales Service* professional sales team.* 24 hours online service.* visit our Factory.After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.