Applicable Industries:Food & Beverage Factory, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Beverage

Packaging Type:CANS, Bottles, Barrel, Stand-up Pouch, Pouch

Packaging Material:Paper, Glass

Automatic Grade:Semi-automatic

Driven Type:Electric

Voltage:220V/380V, 220V/380V 50-60HZ (or customized)

Place of Origin:Shandong, China

Dimension(L*W*H):700*660*1700mm

Weight:80 KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:100BPH, 200BPH

Filling Material:Beer, Milk, Water, Oil, Juice

Filling Accuracy:±0.1

Marketing Type:New Product 2020

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Pump, PLC

Model:BZD-2

Filling Range:10ml-25L(or customized)

Working speed (based on water):10-20 bottles/min

Filling accuracy:±1%

Filling head:2 heads (4 heads orcustomized )

Auxiliary equipment required:Air compressor

Air pressure:0.6-0.8MPA

Machine power:0.55KW

Machine size:700*660*1700mm

Semi-automatic edible oil filling machine / barreled soy sauce and white wine double-head filling machine

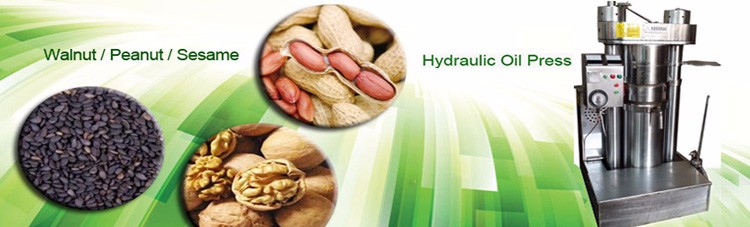

All kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

Crushing peanuts,sesame, pumpkin seeds, linseed, mountain seed, cocoa bean, coffee bean, pepper seeds, walnuts, tea seed, castor, camellia, pumpkin seeds, nuts, olive, black seed, walnut, animal oil fat, almond and other oil crops.

Working priciple

Working priciple

Main Process of cooking oil refinery machine:1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.3. Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Advantage

Centrifugalization is a kind of method using centrifugal force to separate suspended impurities. Through the drum high-speed rotation of the centrifugal force separate the impurities form oil to reach solid and liquid separation. When the drum stops rotating, and net oil flow from the drum to achieve the purpose of filtering . The filtered oil can do edible test , no foam, no overflowed.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

Our company is a professional manufacturer of food oil machines. On the basis of advanced equipment and workmanship, we have excellent production technicians and an efficient distribution team, as well as good service staff members, so that we can undertake your orders very efficiently and offer services very effectively. When we have the confidence on the high quality of our products, we offer very competitive prices at the same time. Our business depends on your business and our purpose is “supporting you”. We mainly provide popular products with high quality at home and abroad and create competitive advantages for our customers for their own competition. In addition, you can suggest any design or give any special requirement for our products and we will do our best to settle them for you. We believe our honesty and sincerity will make any cooperation agreeable. We look forward to long-term and prosperous cooperation with customers around the world. If you have any inquiry, please don’t hesitate to contact us and we are on duty during the whole 24 hours. Your satisfaction is exactly what we pursue. Best wishes for your business along with our sincere gratitude for your attention.

Service

Pre-sales service1.Quick response2.Detailed quotation3.Professional production and transportation solutionAfter-sales service1.Warranty policy one year from shipment2. We will send you the replacement after received the broken part3. Evaluate the customs risk and choose safest shipping company before shipping.4. Follow status up time by time until the goods arrived.

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.