Applicable Industries:Hotels, Manufacturing Plant, Food & Beverage Factory, Home Use, Food Shop, Food & Beverage Shops

Showroom Location:Turkey, Saudi Arabia, Kenya, South Korea, Nigeria

Condition:New

Application:Food, Beverage, Chemical

Packaging Type:Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Bags

Packaging Material:Plastic, Paper, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V, 3Phase, 50Hz

Place of Origin:Jiangsu, China

Brand Name:ALPS

Dimension(L*W*H):3400x2200x2500mm

Weight:5500 KG

Warranty:1 Year

Key Selling Points:Flexible Manufacturing

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, Other

Filling Material:Beer, Milk, Water, Oil, Juice, Drinking Water

Filling Accuracy:0.05%F.S.

Marketing Type:Hot Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:3 years

Core Components:Motor, PLC, Gearbox

Name:Full Automatic Complete A To Z Mineral Bottle Water Production Line

Function:Washing Filling Capping

Machine Main Material:SUS304/316

Suitable Bottle:PET/Glass

Bottle Volume:200ml to 2L

Filling Speed:2000-24000bph

Filling Type:Gravity Filling

Control:PLC

Main Motor:ABB

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Egypt, India, Thailand

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field maintenance and repair service

Certification:CE

Full Automatic Complete A To Z Mineral Bottle Water Production Line

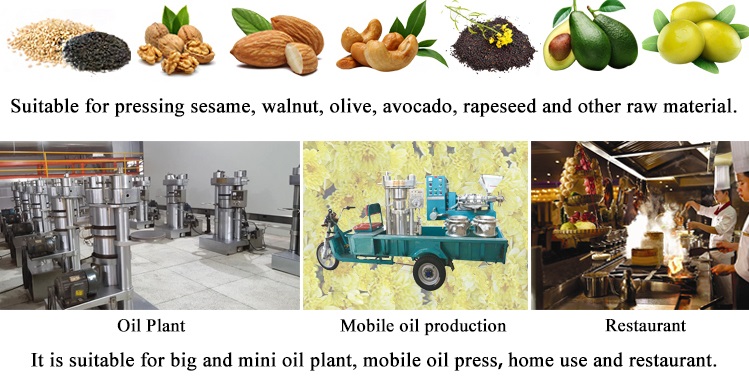

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Raw material

Without shell nuts (sea coconut), maple seed kernel (traditional Chinese Medicine), seed kernel (traditional Chinese medicine),Cinnamomum camphora (traditional Chinese Medicine), castor bean (traditional Chinese Medicine), five seeds, safflower seed and so on.

Working priciple

Working priciple

Cold pressing and hot pressing mode for oil press customer consultation:1. Cold pressing refers to the direct pressing of materials without stir-frying;2. Hot pressing means that the material is heated to 60-80 degrees and then put into pressing;3. No matter cold pressing or hot pressing, our oil press must preheat. Only when the press chamber is preheated to about 200 ℃ can the oil be separated from the material.If the machine is not heated, the material will only be extruded into a paste, and the grease cannot be separated.4. Under the cold pressing mode of the material, the normal temperature of oil coming out is about 40°, and the nutrients will not be lost. Under the material hot pressing mode, the oil yield will be higher, the oil will be more fragrant, the oil will come out at a temperature of 60-80 degrees, and some nutrients will be lost.5. Therefore, the hot pressing mode is generally suitable for pressing rapeseed, peanuts and other low-value edible oils, and the pursuit is oil yield and aroma of cooking;The cold pressing mode is generally suitable for pressing walnut oil, flaxseed, almond, olive kernel and other high nutritional auxiliary oil to ensure the nutrition is not lost.

Advantage

01. High production capacity and good quality final product oil:6YY series hydraulic oil press machine adopts most advanced technology. It can make 35-120kg/hour. Squeezed oil contains little impurities and high nutrients.02. Easy operation, less labor and low labor intensity:6YY series hydraulic oil press machine is simple to operate, only 1-2 workers needed. Training will be provided, also easy to learn.Workers only need to check on the machine, no much work to do.03. Small spaced needed & Low power consumption:6YY series hydraulic oil press occupies at most 2 meters at height, 2.8 meters at length, 1.3 meters at width. You can easily put it in your yard or farm to start your own business. Even better, low power needed to operate. It can save much money on electricity.04. Less investment and more profit:1-2 workers needed, it can save 60% labor at the same output. It can your investment on workers 40 yuan per day, 1200 yuan per month. It is 22400 yuan annually.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

1.We have successfully obtained 27 national patents (including 8 invention patents), 6 international awards, 4 national awards and 2 provincial awards.2.We have the most complete production certificates of oil machines, such as “Design license of pressure vessel”,”Manufacture license of pressure vessel”,”Design license of pressure pipeline”,”Installation,reconstruction and maintenance license of pressure pipeline”, “Manufacture license of organic heat carrier furnace” and installation certification of mechanical and electrical equipment”.3. We are outstanding member enterprise of CCOA (Chinese Cereals and Oils Association), so we produce machines according to standard, and refined oil reaches the best edible oil standard.4.We have strong R & D team, production team and installation team, offer perfect after-sale service, after delivering goods, we will dispatch technicians to instruct installation, commissioning and train your workers to operate machines by yourselves.5.We are provincial enterprise abiding by contracts and keeping promises, we have produced oil machines for 65 years, with rich experience and own brand, so we are responsible for all of our projects, especially for oversea projects.6.Overseas projects: we are establishing every perfect overseas sample project all over the world, such as Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia, Bangladesh, Thailand, the Philippines, Myanmar, Egypt, Sudan, Nigeria, Rwanda, Tanzania, etc.Our company can provide you with 10 to 25 kilograms (test equipment), 2 to 1,000 tons / day of oil refining projects , QiGroup naturally is your preferred partner for different oil quality. in Henan Huatai here are different options, batch chemical refining, semi-continuous physical refining, continuous physical refining program, where Henan Huatai provide you with the design (process, civil, electrical), manufacturing, installation, commissioning, training of technical personnel to the sale a full-service; advanced automatic control system to ensure that the entire production line of automatic, smooth operation; heat saving each segment to ensure that the processing costs to a minimum.

The main refining plant processes: degumming, dehydration, bleaching, deacidification, deodorization, dewaxing, degreasing. Crude oil in squeeze, extraction crude oil can be obtained national quality standards of edible oil through

Service

1.we can free offer complete set 3-500 tons/24 hour cooking oil plant project offer . 2.we can do turn-key project, including design,installation, test and training 3.One-year free spare parts. 4.One-year quality gurantee. 5.Lifetime service.

FAQ

Q1: What does Eternal need from me to quote a price?1.Raw material2.Production capacity per hourQ2: What is the oil yield?The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.The oil residual of our small hydraulic oil press machine, cold press virgin coconut/avocado/olive oil extraction extracting machine is 6%Q3: Can I use the machine to extract several kinds of raw materials?Yes,of course. such as sesame, sunflower seeds, soybean, peanut, coconut, etcQ4: Can I do extraction test with my own raw material?Yes,of course.We can do extraction test and send you videos and test report for your Reference.Q5: What is your material of your machine?