Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco

Packaging Type:CANS, Bottles, Capsule

Packaging Material:Plastic, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:110V, 220V

Place of Origin:Guangdong, China

Dimension(L*W*H):2000*1000*2100mm

Weight:500 KG

Warranty:5 years

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 2000BPH

Filling Material:Beer, Milk, Water, Oil, Juice, Powder

Filling Accuracy:±1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pump, PLC, Motor, Pressure vessel, Pump, PLC

Product name:Liquid filling machine

Processing Types:Filling Capping Labeling

Control:PLC+ Touch Screen

Material:SS304/316

Filling material:honey/jam/tomato paste/shampoo/oil

Filling volume:50-5000ml(customized)

Filling speed:100-3000BPM(customized)

Filling head:2/4/6/8/10(customized)

Air pressure:0.4-0.6 MPa

Automatic 6 Heads Filling Machine The Liquid Products Alcohol Hand Sanitizer Gel Explosion Proof Paste Servo Filling Machine

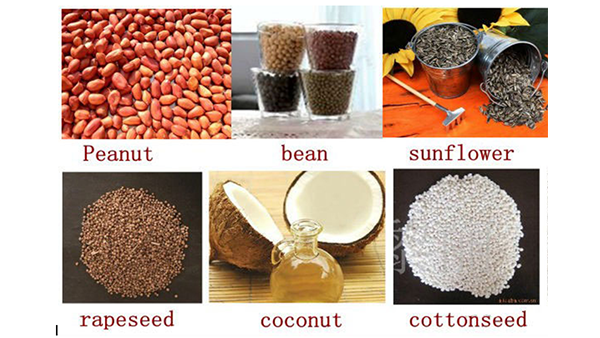

This oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ,etc.

Raw material

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

Pre-Sales Service* Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

Product Specification

Product Specification

| item | value |

| Voltage | 380V |

| Dimension(L*W*H) | 1200x550x1050mm |

| Weight | 130KG |

| Max Capacity | 500 kg/h |

| Product name | Oli Press Machine |

| Raw material | Palm Fruit |

| Function | Press Oil Seeds |

| Application | Edible Oil Production |

| Advantage | Energy Saving |

| Keyword | Small Capacity Oil Press Machine |

| Material | 304 Stainless Steel |

Company Profile

refining plant .adjustable, flexible operation, high automatic degree of sanitation.

Applicable oil: soybean oil, sunflower oil, rapeseed oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil, animal oil all need refining oil.

Refining plant capacity: 10-1000T / D

Service

1, 1 year free warranty. Whole lifetime maintenance.2, Supplying wearing parts all year around.3, Supporting technical solutions at any time.4, Helping design and plan the oil plant’s construction.5, Providing installation video.6, Tried orders are available.7, Developing agents with good policies around worldwide.Service before sale1.One-on-one exclusive customer service staff, 24 hours online.2.Inquiry, email, message will be replied at first time.3.Supply professional technical parameters, video picture sharing, project design.Service on sale1.Ensure customer payment security.2.Ensure the customer’s price is stable and reasonable.3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good. Service after sale1.Arrange high-efficiency delivery and safe transport.2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.

FAQ

Q1:What the terms of payment you accept?A1:T/T 50% deposit first, balanced 50% should be paid before delivery.Q2:Does you have stock now?A2:Yes we have enough stock to meet your larger orders.Q3:What materials your machine can press?A3: Our hydraulic oil press machine can press kinds of materials, such as soybean, sesame, cottonseed, walnut, camellia、peanut and so on.We can also test especial materials for you.Q4:Can your machine work at a low temperature?A4:Yes. Our machine has the heating system to fit for the low temperature, increase oil rate.Q5:How long is your guarantee?A5:One year guarantee, we supply free exchange for spare parts. After this period, we offer the spear parts with facotry price. You will be welcomed to contact us with any problem might occurred.