Brand Name:chaomaida

Dimension(L*W*H):22000*400*750mm

Place of Origin:Guangdong, China

Voltage:220V/380V

After Warranty Service:Video technical support

Applicable Industries:Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location:None

Material:Rubber

Material Feature:Oil Resistant

Structure:Belt conveyor

Power:2.2 KW

Warranty:1 Year

Width or Diameter:40mm

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Marketing Type:Hot Product 2019

Warranty of core components:1 Year

Core Components:Motor

Weight (KG):400 kg

U-belt conveyor 180 turning machine Ring conveyor assembly line Belt assembly line

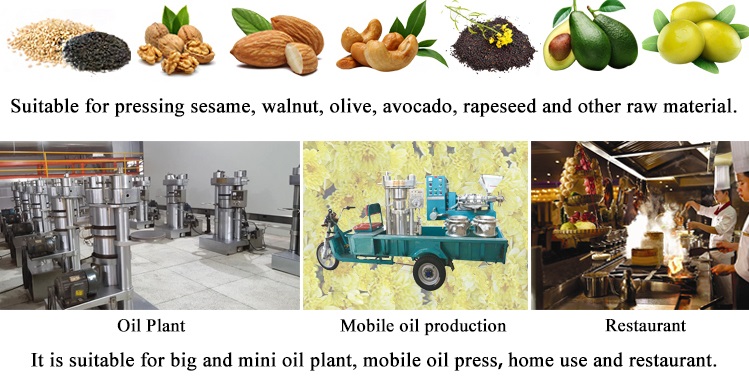

soybeans, perilla seed, shelled hemp, flax seed, flax seed,camellia seed, walnut, black sesame, rapeseed, sesame, sunflower seed.Sunflower seeds, almonds, red / white pepper seeds, peanut, pumpkin seeds, pine nut, coconut meat.

Raw material

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Working priciple

Working priciple

Centrifugalization is a kind of method using centrifugal force to separate suspended impurities.Through the drum high-speed rotation of the centrifugal force separate the impurities form oil to reach solid and liquid separation.When the drum stopsrotating,and net oil flow from the drum to achieve the purpose of filtering.The filtered oil can do edible test,no foam,no overflowed.

Advantage

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Product Specification

Product Specification

| Item | 5TPD Peanut oil production line |

| Capacity | 5TPD |

| Power | 44kw |

| Installation size | Oil pressing line+oil refining line+oil filling line15m*2.5m*4.5m(L*W*H) |

Company Profile

Pre-Sales Service* Inquiry and consulting support. After-Sales Service* Training how to install and function the machine.* Engineers available to service machinery overseas.* 12 months warranty and life spand service available.* Flowchart and factory design. * View our Factory.

Service

1.12 months warranty ,including core parts;2.Video support and online technical guidancem forever;3.Offer video support and online technical guidence at any time;4.Supply spare parts all the world;5.The worldwide agents have good policies and greatest support.

FAQ

Q1 : Which kind of other materials can be processed?All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel, coconut, peanut, soybean, sesame, cottonseeds, rapeseed, etc.but will have some oil equipment is different,we will design the best palm oil mill for you.Q2 : What’s the capacity of this refined oil mill?Generally, 10-5000 tons per day. We can also manufacture as per customers’ requirements.Q3: What is the Material of this machine?Stainless steel and carbon steel,and we accept customization.Q4 : How long is the warranty?The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.Q5 : Can the machine be installed locally?We can do the turn-key projects or other services according to customers’ requirements, according to this condition, our services include manufacturing, purchasing, transporting, installation, training labors etc.Q6 : How long can we get the goods?We usually delivery in 3-5 working days, we will inform you shipping time based on your seaport.