Showroom Location:None

Condition:New

Usage:Sunflower olive palm peanuts sesame nuts corn

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:60%-70%

Place of Origin:Jiangxi, China

Brand Name:dulong

Voltage:380V/220V

Dimension(L*W*H):115*45*135cm

Weight:300 KG

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil

Max Capacity:60 kg/h

Material::Stainless steel

Advantage::Easy use,energy saving,simple

Input(raw material ):40-60kg/h

Feature::Cold pressing and hot pressing

Control mode:full automatic

Packaging Detail::Wooden case

Working Life::6-8 years

Type::Cold & Hot Pressing Machine

Use for::Peanut,beans,sesame,sunflower,rapeseed etc

MOQ::1 set

After Warranty Service:Online support

Local Service Location:None

After-sales Service Provided:Online support

Certification:CE

40-60kg/h CE approved small cold press oil machine/coconut oil extractor

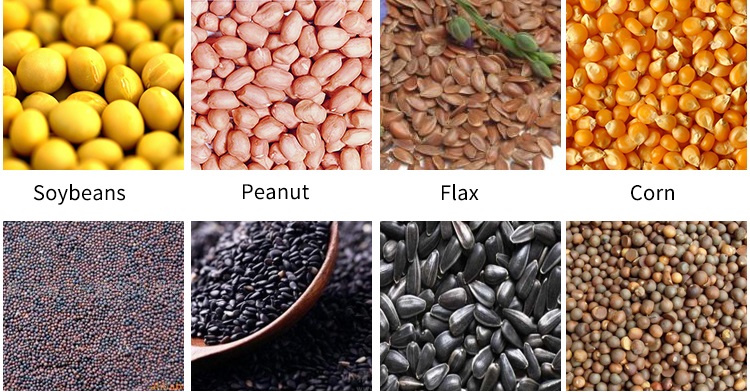

This oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ,etc.

Raw material

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

Simple structure, easy to use, adaptable, high oil rate, energy-saving, and low noise. This series of machinery can be widely used to more than 20 kinds of easy and difficult plant oilseeds, such as peanuts, soybeans, rapeseed, cottonseed, sesame, olives, sunflowers, coconut, cocoa, seeds and so on. During pressing, it can be entirely squeezed one time except for some individual varieties.

Product Specification

Product Specification

| Processing capacity | 3.5T–11T Per day. |

| Residue oil of the cake | ≤7.8% |

| Temperature control power | 3.0kw |

| Main electromotor power | 11kw |

| Spiral axes rotate speed | 32-40 |

| Weight | 1000kg-1400kg |

Company Profile

We are a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Service

Pre-sale service1. Offer the professional solution and design drawing.2. Accept the customized model machine3. Accpect to visit factory4. Ffree testing5. Offer professional quotation6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service.

FAQ

1.Are you a trading company or a manufacturer?We are a manufacturer.2.How to study to operate this machine?You may View the operation video to study how to operate it.3. If the machine is damaged during use, how to maintain it?Please contact us to obtain the spare parts support.4. What is the price?We offer a price range on the website, If you want to know the exact price, please inform us of the port of destination.5. I’m a stranger to large machines, what should I do?we provide paid services such as the installation, debugging and technical training to customers who buy large machines. Of course, You can also come to our factory for free training.6.How to become a local agent?If you want to be an agent to develop the local market, please contact us.