Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Advertising Company

Weight (KG):300

Showroom Location:Canada, Germany, Viet Nam, Philippines, Brazil, Peru, Indonesia, India, Mexico, Spain, Thailand, South Korea, Chile, UAE, Colombia, Algeria, Romania, South Africa, Nigeria, Malaysia, Australia, Morocco

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1.5 years

Core Components:PLC, Engine, Motor

Place of Origin:China

Key Selling Points:High Productivity

item:Cotton Seeds Hemp Oil Extractor

spare part:Oil press filter cloth

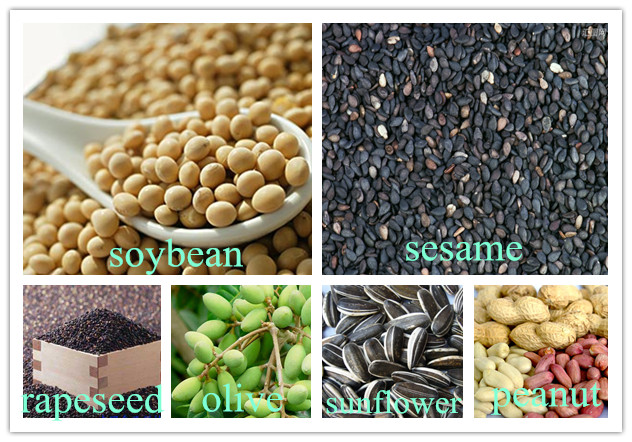

Raw material:Soybean Peanut Sesame

Used for:Sesame Oil Making

Application range:Food Edible Oil Produce

Keyword:Screw Oil Extracting Machine

Extraction of Oilseeds:90% Oil Yield

Oil rate:45%-60%

Delivery:7 Days

Function:Making Edible OilThis oil press with cold and hot pressing function,fit for more than 20 kinds of materials:such as Peanuts,sesame,walnut,rapeseed,sunflower,soybeans,castor beans,pumpkin seeds,eans,watermelon seeds,moringa seeds,pine nuts,hazelnut kernels,almonds.various materials: sesame, walnut, chestnut, cashew, pine nuts, baobab seed, cocoa butter, Argan nuts, avocados, olives, grape seeds, camellia seeds, prickly pear seeds etc.

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.Below features are based on oil plants above the average quality smoothly and continuously squeezed after such treatments as screening, husking, flaking and cooking, etc.Screw Soybean Seeds Oil Press / Groundnut Oil Mill Machine.Our machine adopt sea worthy wooden case packaging, safe and reliable.

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.Below features are based on oil plants above the average quality smoothly and continuously squeezed after such treatments as screening, husking, flaking and cooking, etc.Screw Soybean Seeds Oil Press / Groundnut Oil Mill Machine.Our machine adopt sea worthy wooden case packaging, safe and reliable.

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

We are a professional manufacturer and exporter of mechanical equipment. Our products include edible oil process machines.Our well-equipped facilities,complete after-sale service system and excellent quality control system on all stages of production enable us to satisfy customers from different countries. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.Pre-saleSystem evaluation: Project basic situactionSolution: The investment budget ,Technical discussionProduct selection: Factory inspection,Technical discussion Supply professional drawing and listsWin-win cooperation: Sign the contract,Wstablish mutual benefit In-saleDesign evaluation: Detailed technical assessment, Design of process and equipment layoutProcurement: Strictly inspection,optimized selection.Installation: Quality and quantity guaranteed,Completion of hand overAcceptance: Acceptance test , Accepted deliverables After-saleTechnical service: Long time technical serviceAccessories supplying: Supplying spare parts with costComplaint handling: 12-24 hours response mechanismClient Review: Call-back , Regular return visit.Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.