Showroom Location:None

Condition:New

Usage:oil press machine

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:40-600kg/h

Place of Origin:Henan, China

Brand Name:HDC

Voltage:380V/50HZ/Triple phase

Dimension(L*W*H):Depend on different model

Weight:Depend different model on

Warranty:1 Year

Key Selling Points:High Productivity

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, sunflower seed oil, Almond Oil, Peanut Oil, Coconut Oil

Max Capacity:750 kg/h

Raw material:Peanut, Sunflower, Sesame, Olive, Rapeseed, Soybean etc.

Name:Screw Oil Press Machine

Product name:Screw Press Oil Expeller

Function:Oil Pressing Peanut, Sunflower, Sesame, Olive, Rapeseed, Soybean etc.

Application:Oil Production Line

Advantage:Energy Saving, High Oil Yield etc.

Material:Carbon steel or stainless steel

Output:40-600kg/h

Keyword:Screw Type Oil Expeller

Section:Pretreatment, press, meal extraction & oil refinery machine section

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Video technical support, Online support

Certification:CE, ISO

Automatic Cold and Hot coconut Sunflower Oil Presser Screw Press Machine

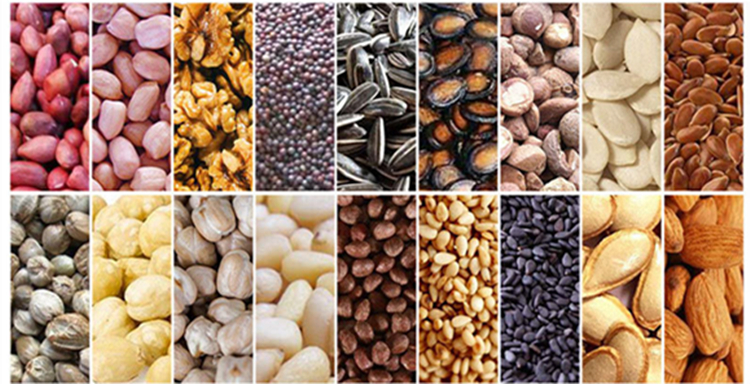

This machine for coconut oil ,are also be fit for Almost all of the grain seeds can be pressed to make edible oil, such as corn, soybean, peanut, sunflower seed, flax seed ,coconut ,palm , rape seed.sesame, Olive, walnut,cocoa bean.,rice brain ,cotton seed ,castor seed.

Raw material

Hot and cold automatic modern oil press is a new product developed by our company. It can press rapeseed, peanuts, tea seed, soybean, sesame, sunflower and other oilseeds, the machine is equipped with micro electric control, infrared heating, filtration system, multistage press.

Working priciple

Working priciple

Crude seeds→ cleaning → softening → expanding → drying → to extraction workshop; Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect.

Advantage

(4)After the end of each shift, the residual cake in the machine should be removed and the dust and grease on the surface of the machine should be wiped clean.(5) When storing for a long time after the end of the production season, maintenance should be carried out once, and the snails, the squeezed strips, the cake strips should be removed and washed and re-applied, and placed in a dry place.

Product Specification

Product Specification

| Usage | sunflower oil production line |

| Type | Cold & Hot Pressing Machine |

| Automatic Grade | Automatic |

| Place of Origin | China |

| Voltage | 220V/380V/440V |

| Oil type | Sunflower Seed Oil |

| Max Capacity | 3000tpd |

| Product name | Vegetable Oil Sunflower Cooking Oil Production Line Of Edible Oil |

| Raw material | Sunflower seeds |

| Factory visit | welcome |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

1.Fast DeliveryWe are factory direct sale; we produce and export machine directly2.Competitive priceDirect raw material+cheaper labor= our competitive price3.On-time shipmentCredit&Quality is first! Machine is ready for our own sea/air shipping.4.Quality inspectionOwn advanced manufacturing equipments andcomputercontrolled making machine, so our factory implementassembly line entirely.5.QCStrict quality control system to guarantee 100% high quality.6.SincerityCooperation=whole life friendship. Not only the machine, but our Credit!

FAQ

Q:Are you a manufacturer or a foreign trade company?A:We are a manufacturer.Q:What if I could not operate this product?A:There is peration video and manual for you. If necessary, we will send engineers to train for you personally.Q:Can you provide more information about production and quote the best price?A:Of course, but first we have to confirm your needs. According to your needs, we will choose the right product for your reference. When we determine one or several products, we will quote you the best price.Q:How to place an order?A:First send us the enquiry below, including the device name, daily production, work hours, main processing materials, etc., then our sales manager will send you the information for your reference.Q:How long does it take to receive my product?A:It is not yet possible to determine the time because the shipping distance and production cycle are uncertain.our business manager will recommend the appropriate transportation route for you to ensure safe and fast delivery of the goods.Q:How is the quality of your products guaranteed?A:After the completion of production, our quality inspection can not test the product. If you need it, we can provide third-party testing service to ensure the stable production of the equipment.