Type:Centrifuge

Product Type:Infused Solution

Condition:New

Video outgoing-inspection:Provided

Machinery Test Report:Not Available

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel

Brand Name:Touch Science

Voltage:220v

Power:4000

Weight:900kg

Dimension(L*W*H):1670*1070*870mm

Warranty:1 Year

Key Selling Points:Easy to Operate

Applicable Industries:Manufacturing Plant, Farms, Retail, Lab

Showroom Location:None

Application Industries:Chemical Industry

Main Uses:Separation, Extaction

Material:SUS

Capacity:200L

Rotating Speed:800r/min

Drum Volume:200L

Separation factor:270wsqr/g

Motor Power:4kw

Drum thickness:6mm

Name:Bag Filter Centerfugal Marihana Cbd Oil Ethanol Extractor

After-sales Service Provided:Online support

After Warranty Service:Online support

Local Service Location:None,attrValueId:3270618

Jacketed Centrifuge Extractor Winterizer Bag Filter Centerfugal Marihana Cbd Oil Ethanol Extractor

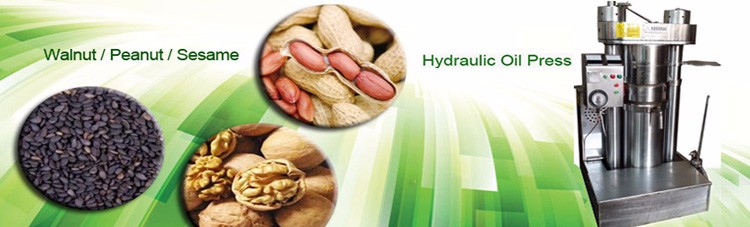

Pretreatment Applicable oil: soybean, rice bran, sunflower, rapeseed, cottonseed, walnuts, corn germ, peanuts, copra, castor bean, palm kernel, palm nuts, sesame, olive and the like.

Raw material

Hydraulic Screw Cold and Hot Oil press machine is suitable for the pressing of various materials: sesame, walnut, chestnut, cashew, pine nuts, baobab seed, cocoa butter, Argan nuts, avocados, olives, grape seeds, camellia seeds, prickly pear seeds etc.

Working priciple

Working priciple

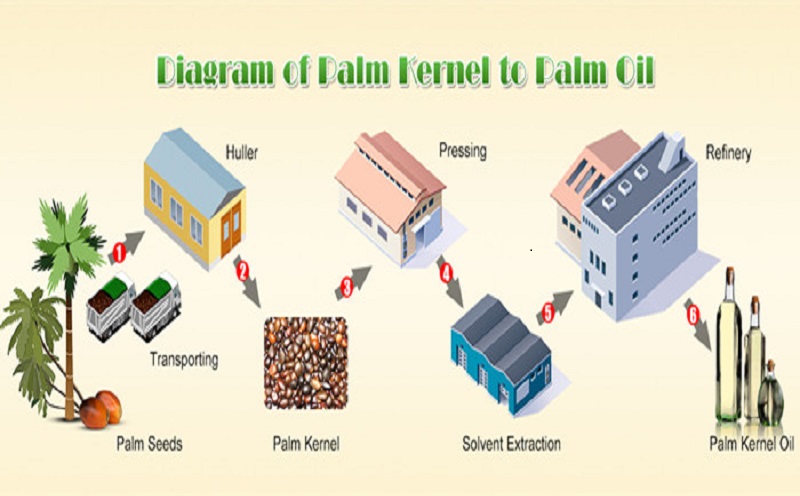

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

High oil yield – The oil yield can be improve 2 to 3 percentage points than older equipment.Energy saving – With same output reduces electricity power by 40%.Labor saving – With same output can save 60% of labor, and 1 to 2 people can organize production.Pure oil – Vacuum filtration residue to ensure the purity of oil, in line with health and quarantine standards.Small footprint – 10-20 square meters to meet the needs.Precision manufacturing – High alloy carbon steel, high frequency quenching and heat treatment, which improves the service life of the oil press.

Product Specification

Product Specification

| Model | Capacity(kg/h) | Power(kw) | Machine Size(mm) | Weight(kg) |

| 6YL-80 | 100kg/h | 5.5kw | 1307x550x1102 | 350kg |

| 6YL-95 | 200kg/h | 7.5-11kw | 2155x580x1250 | 620kg |

| 6YL-100 | 200kg/h | 7.5-11kw | 2050x550x1180 | 520kg |

| 6YL-120 | 300kg/h | 11-15kw | 2150x610x1300 | 620kg |

| 6YL-125 | 350kg/h | 11—15kw | 1750x570x1320 | 620kg |

| 6YL-130 | 450kg/h | 15-18.5kw | 2180x610x1480 | 800kg |

| 6YL-160 | 550kg/h | 18.5-22kw | 2180x610x1480 | 1000kg |

| 6YL-165 | 700kg/h | 22-30kw | 2280x620x1680 | 1700kg |

Company Profile

We have abundant experience in product research, strong technical force, sophisticated production, and specializing in production of oil press machine, the main products are automatic Hydraulic oil press, and related products: wok, vibrating screen, peanut sheller, sesame feeding machine, oil filter machine, spiral hoist, automatic seed feeding machine. Our hydraulic oil press is suitable for a variety of oil crops(sesame, peanut, walnut, mustard, olive, sunflower and more), all parts of the machine are made up of premium alloy steel and excellent craftsmanship, won an excellent reputation and satisfaction among customers.Welcome customers from worldwide come for a visit to our factory!

Service

Pre-Sales Service* professional sales team.* 24 hours online service.* visit our Factory.After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

FAQ

1.Are you a trading company or a manufacturer?We are a manufacturer.2.How to study to operate this machine?You may View the operation video to study how to operate it.3. If the machine is damaged during use, how to maintain it?Please contact us to obtain the spare parts support.4. What is the price?We offer a price range on the website, If you want to know the exact price, please inform us of the port of destination.5. I’m a stranger to large machines, what should I do?we provide paid services such as the installation, debugging and technical training to customers who buy large machines. Of course, You can also come to our factory for free training.6.How to become a local agent?If you want to be an agent to develop the local market, please contact us.