Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Production Capacity:10T/24h

Place of Origin:Henan, China

Brand Name:Ocean

Voltage:380V

Dimension(L*W*H):2005*1610*2010mm

Weight:806kg

Warranty:1 Year, 12 Months

Key Selling Points:Long Service Life

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Gear, Bearing, Gearbox

Raw material:Soybean/ Seasame/ Sunflower seed/

Function:Oil Pressing

Application:Screw Oil Expeller

Color:Customized

Material:Stainess Steel

Feature:High Oil Yield Efficiency

Quality:Stable

Used for:Oil Processing

Product name:New type screw soybean oil extraction machine

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Certification:CE/OHSAS

New type extrusora de soja soyabean oil pressing machine soybean processing machine

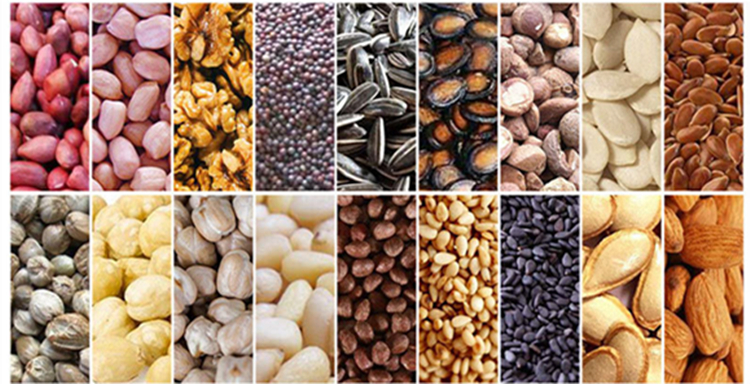

It can be used for various materials such as Peanuts, Rapeseeds, Sesame seeds, Soybeans, Cottonseeds, Tea seeds, Sunflower seeds, Palm kernel etc.

Raw material

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1. 304/316 SUS 2.Multifunctional, Degumming,deacidification,decolorization,Dehydration3. Smart control, no leakage and overload. 4. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Made in china seeds oil press machines/cottonseed oil expellerSpecification : | ||||

| Model | Capacity (ton/day) | Power (KW) | Packing size( mm) | Gross Weight (KG) |

| AST-80 | 2~3 | 5.5 | 1510x440x695 | 370 |

| AST-95-1 | 3~5 | 7.5 | 1920x620x770 | 700 |

| AST-100 | 3~5 | 7.5 | 1920x650x770 | 710 |

| AST-120 | 4~6 | 11 | 2060x630x790 | 720 |

| AST-120C | 6~8 | 15 | 2100x700x800 | 750 |

| AST-130 | 9~12 | 18.5 | 2300x700x770 | 850 |

| AST-160 | 15~20 | 22 | 2500x700x850 | 980 |

Company Profile

We are a large scale oil machinery manufacturer integrating research, development, design, manufacture and installation. Established in 1982, we have 210 senior engineering technicians among 580 staff, with investment amount of USD60,000.000, covering 10 hectares of factory area, 8 production workshops, 2 machining workshops,12 installation departments.We have 202 sets of automatic processing equipment, annual processing capacity is more than 3000 sets.Our oil machines sell well in more than 30 provinces, cities and districts, and exported to Kazakhstan, Tajikistan, Uzbekistan, Russia, Bolivia, Peru, Egypt, Bangladesh, Myanmar, Malaysia, Indonesia,Solomon Islands, Sudan, Rwanda and other countries and regions, and now we have developed into a major oil machinery manufacturing base in China.

Service

Pre-Sales Service* professional sales team.* 24 hours online service.* visit our Factory.After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

FAQ

a discount.Q8: Do you have machines in stock?Yes, we have some models oil press in stock.Q9: How will my order be packed, can you provide the installation service?Packed in plywood case. We will send English manual. If the customer need, we will send one engineer for assembling and training for workers.