Applicable Industries:Hotels, Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location:None

Application:Food, Beverage, water/drink/beverage/juice

Packaging Type:CANS, Bottles, Barrel, case

Packaging Material:Plastic, Metal, Glass, Wood, Other

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V

Place of Origin:China Guangzhou

Brand Name:TZ

Weight:480 KG

Warranty:1 Year

Key Selling Points:Energy saving

Machinery Capacity:1000~5000BPH

Filling Material:Milk, Water, Oil, Juice, sauce jam

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Bearing, Engine

Product name:small drinking water high quality pure Water

Keywords:Automatic Fillling Machine

speed:about 1000-5000 bottles / hour

Program control:PLC + touch screen

Number of label:1pc

labeling accuracy:99%

Power:about 2.5KW/AC220V/380V 50/60HZ

Conveyor belt:82mm 114mm 192mm wide stainless steel chain belt, speed 0-15 m / min

After Warranty Service:Video technical support

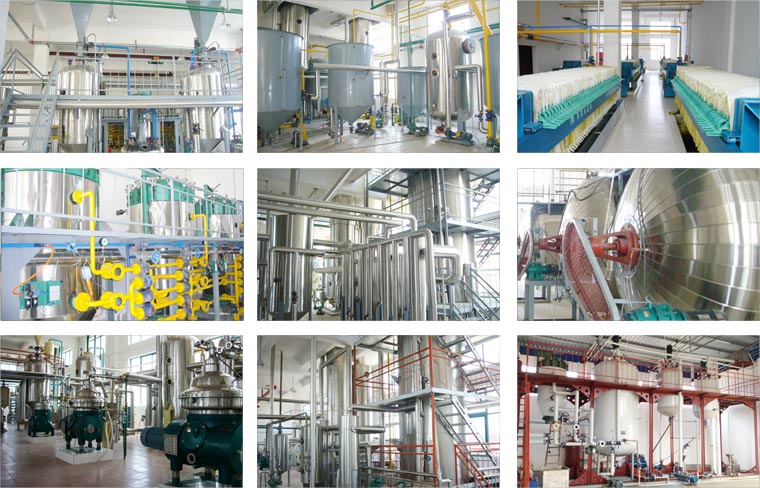

Automatic peanut butter jam oil food liquid sauce paste filling machine Production Processing line

Hot and cold automatic modern oil press is a new product developed by our company. It can press rapeseed, peanuts, tea seed, soybean, sesame, sunflower and other oilseeds, the machine is equipped with micro electric control, infrared heating, filtration system, multistage press.

Raw material

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

1.304/316 SUS 2.Customized crude oil refining line capacity. We customize plant as per your requirement for the capacity.3. Flexible usage. The crude oil refining line can work independently or together with whole oil production line.4. Two sets centrifugal machine make sure all continuous production , degumming result is very good.5.The refined oil has high quality and is good for long time storage.6. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you!

Service

1, 1 year free warranty. Whole lifetime maintenance.2, Supplying wearing parts all year around.3, Supporting technical solutions at any time.4, Helping design and plan the oil plant’s construction.5, Providing installation video.6, Tried orders are available.7, Developing agents with good policies around worldwide.Service before sale1.One-on-one exclusive customer service staff, 24 hours online.2.Inquiry, email, message will be replied at first time.3.Supply professional technical parameters, video picture sharing, project design.Service on sale1.Ensure customer payment security.2.Ensure the customer’s price is stable and reasonable.3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good. Service after sale1.Arrange high-efficiency delivery and safe transport.2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.