Product Type:Fruit Oil

Grade:EXTRA VIRGIN

Processing Type:Cold Pressed

Cultivation Type:Organic

Packaging:Plastic Bottle

Purity (%):100

Volume (L):5

Place of Origin:Spain

Brand Name:LACOVALTA

Category:ExtraVirgin Olive Oil

Product Name:Olive Oil 100% Pure Natural Extra Virgin Olive Oil

Classification:Extra Premium

Origin:100% SPAIN

Keywords:Superior Extra Virgin Olive Oil

Usage:Consumption

Size:250ml/500ml/750ml/5l/bulk/flexitank

Extra virgin olive oil:Extra Virgin Olive Oil Made

Color:Golden Green

Variety:Picual

Best Extra Virgin Olive Oil, Maximum Quality Product of Spain, Gourmet, Authentic Traditional Flavor, 100% Picual, Cold Press

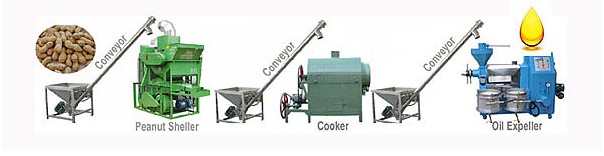

Hot and cold automatic modern oil press is a new product developed by our company. It can press rapeseed, peanuts, tea seed, soybean, sesame, sunflower and other oilseeds, the machine is equipped with micro electric control, infrared heating, filtration system, multistage press.

Raw material

This oil press with cold and hot pressing function,fit for more than 20 kinds of materials:such as Peanuts,sesame,walnut,rapeseed,sunflower,soybeans,castor beans,pumpkin seeds,eans,watermelon seeds,moringa seeds,pine nuts,hazelnut kernels,almonds.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

3)High hardness and strength, good abrasion resistance and long using life.4)Vegetable oil seeds, corn ,sunflower ,soybeans, peanuts, cotton seeds, sesame seeds,palm kernel,coconut etc.5)Compact structure, stable function, simple maintenance.6)Efficient oil producing, easy operating, high automatic.

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We have abundant experience in product research, strong technical force, sophisticated production, and specializing in production of oil press machine, the main products are automatic Hydraulic oil press, and related products: wok, vibrating screen, peanut sheller, sesame feeding machine, oil filter machine, spiral hoist, automatic seed feeding machine. Our hydraulic oil press is suitable for a variety of oil crops(sesame, peanut, walnut, mustard, olive, sunflower and more), all parts of the machine are made up of premium alloy steel and excellent craftsmanship, won an excellent reputation and satisfaction among customers.Welcome customers from worldwide come for a visit to our factory!

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.

FAQ

1.Q:Can you guarantee the quality of your machine?A:We are a professional manufacturer with strict quality requirementsoil press machine2.Q:Does your factory accept customization?A:As a professional manufacturer, we can do almost any kind of customization.3.Q:What’s the delivery time?A:Generally after paying the final payment 3-5 days.4.Q:How long can I receive the goods after placing the order?A:7-15 days if there is no unexpected.5.Q:What should I do if the oil making machine will not be installed?A:Don’t worry, we have a perfect after-sales service system and can provide you video supports for free.6.Q:What’s your terms of payment?A:50% in advance, balance before shipment.