Showroom Location:None

Condition:New

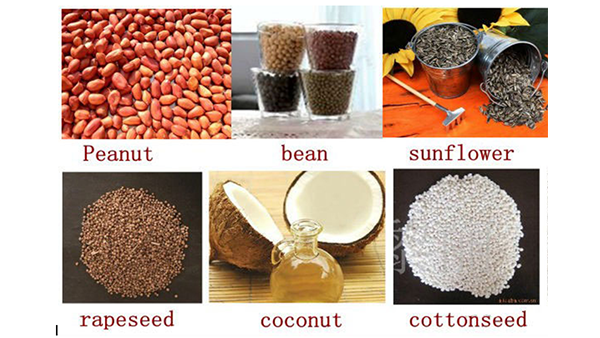

Usage:for sunflower seeds, rapeseed, tea seeds, sesame seeds, peanuts

Type:Oil press

Automatic Grade:Automatic

Place of Origin:Guangdong, China

Brand Name:YTK

Voltage:220/110V

Dimension(L*W*H):66cmX30cmX45cm

Weight:16 KG

Warranty:1 Year

Key Selling Points:Energy saving

Marketing Type:Ordinary Product

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Oil type:Soybean Oil, SESAME OIL, sunflower seed oil, Peanut Oil, OLIVE OIL

Max Capacity:12.5kg/h

Product name:Oli Press Machine

Function:Press Oil Seeds

Material:Stainess Steel

Application:for sunflower seeds, rapeseed, tea seeds, sesame seeds, peanuts, etc.

Raw material:Cottonseed, soybeans, seasame, walnut, oliver, coconut, oil seeds…

Advantage:simple operation

Keyword:Pumpkin Seed Oil Press Machine

Keyword 1:Screw Oil press high extraction

Keyword 2:Stainless Steel Oil Extraction Equipment

Keyword 3:Frankincense Oil Extract Machine

Commercial Corn Olive Press Machine Control Temperature Oil Press Machine Food Grade

the plant is suitable for Soybeans, peanuts, corn, flax, linseed, tea seed(camellia seed), sesame,walnuts, rapeseed, grape seed,castor, sunflower, cottonseed etc.

Raw material

Our Integrated oil press is used widely for processing rapeseeds, cottons, soybeans, peanuts, sesames, sunflowers, tung seeds, olive coconut meat,palm and other granulated oil materials, as well as using for rice bran, corn embryo and powered oil materials and safflower and other wild plant oil materials. It’s regeneration products for medium-small scale plant oil mill in country and private factory,and ideal choice for users to realize well-off life.

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1. 304/316 SUS 2.Multifunctional, Degumming,deacidification,decolorization,Dehydration3. Smart control, no leakage and overload. 4. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

1.We have successfully obtained 27 national patents (including 8 invention patents), 6 international awards, 4 national awards and 2 provincial awards.2.We have the most complete production certificates of oil machines, such as “Design license of pressure vessel”,”Manufacture license of pressure vessel”,”Design license of pressure pipeline”,”Installation,reconstruction and maintenance license of pressure pipeline”, “Manufacture license of organic heat carrier furnace” and installation certification of mechanical and electrical equipment”.3. We are outstanding member enterprise of CCOA (Chinese Cereals and Oils Association), so we produce machines according to standard, and refined oil reaches the best edible oil standard.4.We have strong R & D team, production team and installation team, offer perfect after-sale service, after delivering goods, we will dispatch technicians to instruct installation, commissioning and train your workers to operate machines by yourselves.5.We are provincial enterprise abiding by contracts and keeping promises, we have produced oil machines for 65 years, with rich experience and own brand, so we are responsible for all of our projects, especially for oversea projects.6.Overseas projects: we are establishing every perfect overseas sample project all over the world, such as Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia, Bangladesh, Thailand, the Philippines, Myanmar, Egypt, Sudan, Nigeria, Rwanda, Tanzania, etc.Our company can provide you with 10 to 25 kilograms (test equipment), 2 to 1,000 tons / day of oil refining projects , QiGroup naturally is your preferred partner for different oil quality. in Henan Huatai here are different options, batch chemical refining, semi-continuous physical refining, continuous physical refining program, where Henan Huatai provide you with the design (process, civil, electrical), manufacturing, installation, commissioning, training of technical personnel to the sale a full-service; advanced automatic control system to ensure that the entire production line of automatic, smooth operation; heat saving each segment to ensure that the processing costs to a minimum.

The main refining plant processes: degumming, dehydration, bleaching, deacidification, deodorization, dewaxing, degreasing. Crude oil in squeeze, extraction crude oil can be obtained national quality standards of edible oil through

Service

1.Quality warranty period is two years (except the wearing parts).Equipment must be 100% brand new when leaving factory. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. 2. Whole lifetime maintenance free of charges. 3. Free training course at our plant. 4.Free technical support online or by phone communications&emails.5.Our engineer can be assigned to your country for testing and training as per your requirement.

FAQ

Q:Are you manufacturer?A:Yes,we are manufacturer with more than 20 year’experience.Q:Can you ship the machine to my address?A:Yes,we could use DHL to delivery the machine while the transport cost will be not cheap.And it is suitable for this kind of machine.Q:Where are you?Can we go to China and visit your factory?A:Yes,of course.We are in Henan,China.Welcome to our factory.Q:Do you have manual with the machine?A:Yes,of course.It is in English version.Q:Can you offer us the necessary paper to do the customs clearance?A:Yes,of course.We will send you the commercial invoice,sales contract,packing list,bill of lading(FOB or CFR,CIF terms),insurance policy(if CIF terms),also CO if you need.