Brand Name:WE

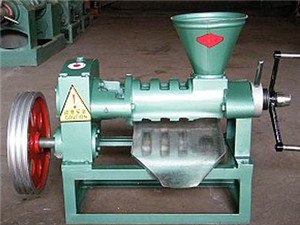

Dimension(L*W*H):800*400*900mm

Weight:65kg

Place of Origin:Henan, China

Voltage:380V

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Brazil, Saudi Arabia, Kenya

After-sales Service Provided:Online support

Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use

Showroom Location:United States, Kenya, Algeria

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:Motor

Warranty:1 Year

Application fields:Fruit processing plant, Cooking oil factory, Cannery, Meat processing plants, Vegetable processing plant, Seasoning plant, Frozen food Factory, Snack food factory, Bakery

Raw material:Nuts, Soybean

Output product name:Peanut butter/paste/Tahini

Power:1.5kw

Certification:CE ISO

Automatic Shea Almond Nut Butter Making Machine Peanut Butter Production Line

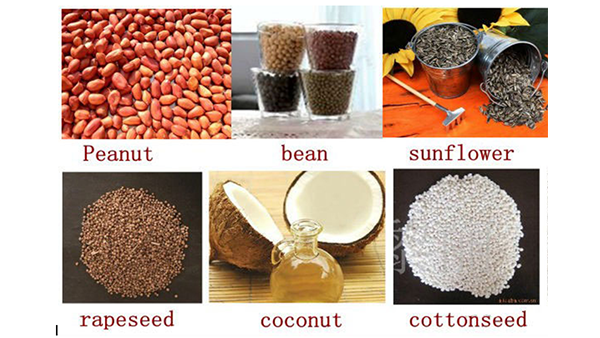

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Raw material

This oil press with cold and hot pressing function,fit for more than 20 kinds of materials:such as Peanuts,sesame,walnut,rapeseed,sunflower,soybeans,castor beans,pumpkin seeds,eans,watermelon seeds,moringa seeds,pine nuts,hazelnut kernels,almonds.

Working priciple

Working priciple

The Motor offers power to Hydraulic Box to squeeze the kinds of materials up and down in the kettle, through the Control System control the working pressure and temperature, stop working when the pressure over the set point(60mpa) automatically, when the pressure reduces to about 50mpa the machine will work again, this cyclic processing can squeeze materials roundly and improve the oil yield.

Advantage

1)Occupied workshop area is small.2)Special gear box structure make the rotating speed averagely.

Product Specification

Product Specification

| Made in china seeds oil press machines/cottonseed oil expellerSpecification : | ||||

| Model | Capacity ( t/day) | Power(KW) | Outside Size(mm) | Weight(kg) |

| AST-80A | 2.5~3 | 5.5 | 1760*1050*1850 | 600 |

| AST-95CA | 3~5 | 7.5 | 2050*1050*1850 | 940 |

| AST-100A | 3~5 | 7.5 | 2050*1050*1850 | 940 |

| AST-120A | 4~7 | 11 | 2220*1050*1850 | 1200 |

| AST-120CA | 6~8 | 15 | 2340*1050*1850 | 1300 |

| AST-130A | 9~12 | 18.5 | 2450*1100*1950 | 1500 |

| AST-165A | 15~20 | 22 | 2600*1200*1950 | 1680 |

Company Profile

Our company has been specially engaged in research, develop and manufacture oil press machines. Our main products are Screw Hot Oil Press machine, Screw cold&hot Oil Press machine, automatic Hydraulic Oil press machine,and the auxiliary products such as Material&Cake lifters, enviromental Electric Roller Roaster, peanut Sheller, Tea seed Sheller, Seed Cleaners , edible oil refining equipment, Oil Filters and so on . Our service network has covered the whole country and exported to Southeast Asia, the Middle East, West Africa, Russia abroad.All our parts are made of the high quality 20CrMnTi alloy steel , processed with the imported equipment through the process of cementit quenching and high frequency quenching.So the high hardness parts make our series of oil press machines distinguished in high oil yield and least wearing and tearing.Qi Feng adhere to the “people-oriented, technology innovation” business philosophy, adhere to the “science and technology service for society, quality seek survival, seek development with prestige” business purpose.Our company staffs warmly welcome customers at home and abroad to negotiate further business to pay visits to our factory for live experience!

Service

Pre-sale services1) Selecting equipment type;2) Designing and fabricating the products in accordance with the special requirements of the clients;3) Training technical personnel for our clients;4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.After-sale services1) Assisting the clients preparing for the first construction scheme;2) Installing and testing the equipment;3) Training the first-line operators on site;4)Supplying spare parts with cost.

FAQ

1.Q :Are you the factory? A:Yes, We are a professional manufacturer for more than 10 years.2.Q: Where is your factory located? A:Our factory is located in Zhengzhou, Henan Province.3.Q:How about the INSTALLATION? A:Engineers are available to service machinery overseas,including installation,commission and training,etc. 4.Q:Can your company accept the customized product? A:Yes,OEM &ODM service is available.We can make the products according to your size,design,color, It will be better if you can send us the product pictures for our reference.5.Q: How does your factory do regarding quality control? A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.Any questions, please don’t hesitate to contact us!