Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Food & Beverage Shops, Juice Filling Machine Drinking Water, Pure Water Filling Line

Showroom Location:Canada, Turkey, United Kingdom, Indonesia, Morocco, Colombia, South Africa, Ukraine, Uzbekistan, Tajikistan, Japan, Australia

Condition:New

Application:Food, Beverage, Filling Machine

Packaging Type:Cartons, Bottles, Barrel, Stand-up Pouch, Bags, Pouch, Water Bottle

Packaging Material:Paper, Glass, Plastic Bottle

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V

Place of Origin:Jiangsu, China

Brand Name:FILLEX

Dimension(L*W*H):2300x850x1400(mm)

Weight:3500kg

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, Water Filling Line

Filling Material:Beer, Milk, Water, Oil, Juice, Pure Water

Filling Accuracy:+-1mm

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine, Juice Filling Line

Usage:Beverage Filling Packaging

Product name:Fruit juice making filling bottling machine

Processing:Filling+stoppering+capping

Suitable for:Juice / Apple Juice / Orange Juice

Capacity:2000-24000bph

Bottle type:PET Plastic Bottle

Processing Types:Automatic Bottle Filling Sealing Machine

Model:Juice Filling Equipment

Advantage:20 Years Experiences

Feature:High Precision Filling Level

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Germany, Viet Nam, Peru, Saudi Arabia, Indonesia, Mexico, Russia, Spain, Malaysia, Australia, Morocco, South Korea

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE

Automatic Drinking Fruit Juice Making Filling Bottling Machine / Capping Production Line / Mixing Equipment

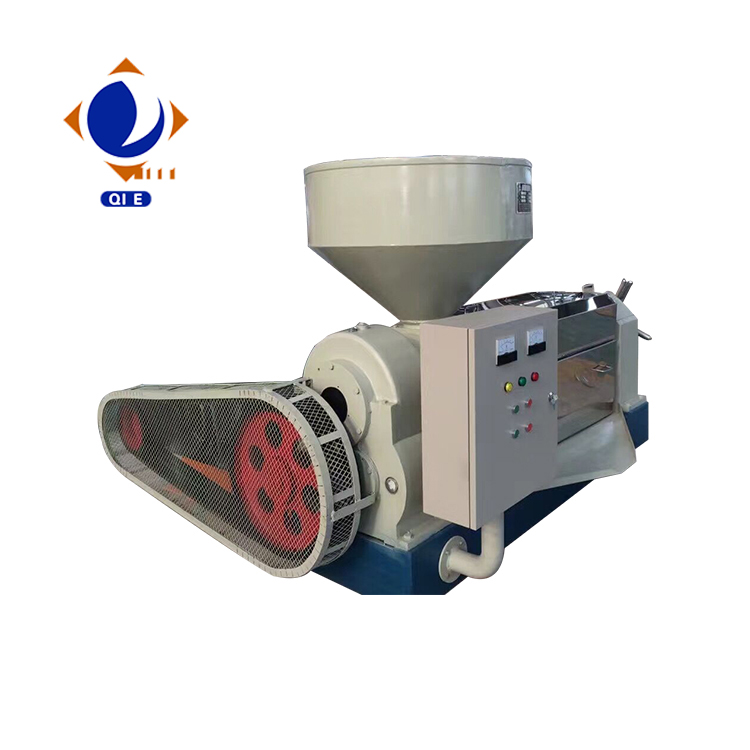

Although 6YL-68 Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Raw material

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more.

Working priciple

Working priciple

Magnitic seperating:In order to remove the metal impurities, so that can prevent damaging the equipment and occuring safety accidents.Cleaning: To remove the imourities in the raw matrial such as soil, stem and leaf, hull and moldy seeds.Husking: In order to improve the oil yielding rate and the quality of crude oil and meal, reduce the wear to the equipment, the hull must be removed.Cooking: This processing can improve prepressing oil yielding rate and the quality of the cake, adjust the moisture, temperature and plasticity of the flake.Prepressing:To squeeze out part of the oil in the raw material, and improve extracting effect.

Advantage

(1)The lubrication should be checked after every 50 hours of operation. The oil cup on the gearbox should not be short of oil. The screw shaft should be adjusted from the adjustment screw hole to the oil in the screw hole. Dry grinding is strictly prohibited.(2)The parts of the oil should be protected from dust and other impurities. The quality of the oil in the gearbox should be checked once a year. If it is found to be deteriorated, all oil should be replaced.(3) When the crushing amount is reduced and the cake or oil is not normal, the screw shaft should be taken out to check the wear of the screw, the strip and the cake ring, and the worn parts should be replaced in time.

Product Specification

Product Specification

| Model | 6YL-60 | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-160 | |

| Dia. | Φ53mm | Φ81mm | φ101mm | φ123mm | φ160mm | |

| Screw speed | 64 r/min | 47r/min | 38r/min | 35r/min | 32r/min | |

| Power | Motor | 1.5-2.2kw | 5.5kw | 7.5kw | 11kw | 22kw |

| Vacuum pump | 0.18kw(VP-1.5) | 0.55kw | 0.75kw | 1.1kw | 1.1kw | |

| Heater | 0.9kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | |

| Capacity | 4.-60kg/h | 80-100kg/h | 150-200kg/h | 250-300kg/h | 500-600kg/h | |

| Weight | 268kg | 880kg | 1250kg | 1500kg | 1800kg | |

| Size(mm) | 1020*720*798 | 1500*1200*1750 | 2000*1300*1850 | 2100*1300*1850 | 2300*1300*1950 |

Company Profile

We are a large scale oil machinery manufacturer integrating research, development, design, manufacture and installation. Established in 1982, we have 210 senior engineering technicians among 580 staff, with investment amount of USD60,000.000, covering 10 hectares of factory area, 8 production workshops, 2 machining workshops,12 installation departments.We have 202 sets of automatic processing equipment, annual processing capacity is more than 3000 sets.Our oil machines sell well in more than 30 provinces, cities and districts, and exported to Kazakhstan, Tajikistan, Uzbekistan, Russia, Bolivia, Peru, Egypt, Bangladesh, Myanmar, Malaysia, Indonesia,Solomon Islands, Sudan, Rwanda and other countries and regions, and now we have developed into a major oil machinery manufacturing base in China.

Service

1.12 months warranty ,including core parts;2.Video support and online technical guidancem forever;3.Offer video support and online technical guidence at any time;4.Supply spare parts all the world;5.The worldwide agents have good policies and greatest support.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.