Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Production Capacity:60%

Place of Origin:Henan, China

Brand Name:Mingxin

Voltage:220V/380v

Dimension(L*W*H):1200*780*1100mm

Weight:800-2000KG

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Name:Automatic mustard oil screw machine small oil expeller

Raw material:peanut, sunflower, coconut, cocoa butter

Capacity:30-350kg/h

Material:Steel

Package:Wooden Case

Market:Global

Application:Making Oil

Quality:Stable Quliaty

Method to press:Screw Squeezed Press

Keyword:Sunflower Seed Oil Mill Press Machine

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Field installation, commissioning and training, Video technical support, Online support

Certification:iso9001 CE

Automatic mustard oil screw machine small oil expeller price in Pakistan

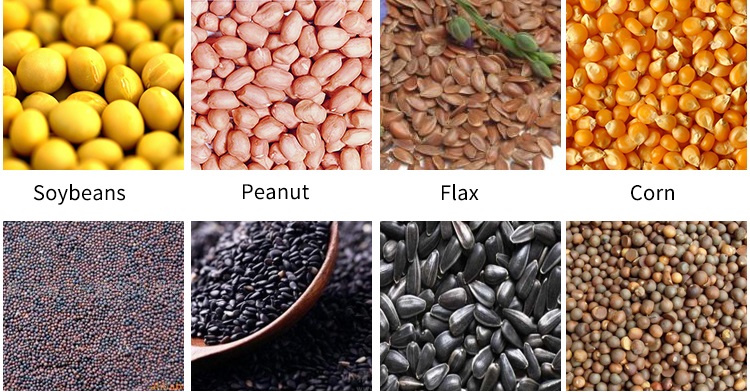

This oil press with cold and hot pressing function,fit for more than 20 kinds of materials:such as Peanuts,sesame,walnut,rapeseed,sunflower,soybeans,castor beans,pumpkin seeds,eans,watermelon seeds,moringa seeds,pine nuts,hazelnut kernels,almonds.

Raw material

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Product Specification

Product Specification

| Model | Capacity | oil content in cake | Motor power(kw) |

| 202 | 40-50 TPD | less than 13% | 30 |

| 204 | 75-80TPD | 15-18% | 30 |

| LYZX24 | 20-25TPD | 10-19% | 30+5.5+3 |

| LYZX28 | 40-60TPD | 15-19% | 45+11+1.5 |

| LYZX32 | 80-100TPD | 15-19% | 90+.5+1.5 |

| LYZX34 | 150-180TPD | 11-15% | 160 |

| SYZX12 | 4-6TPD | 4-6.5% | 18.5+1.1 |

| SYZX24 | Hot pressing 80-100 TPD | 10-17% | 55+7.5 |

| Cold pressing 40-50 TPD | 5-7% |

Company Profile

1.We have successfully obtained 27 national patents (including 8 invention patents), 6 international awards, 4 national awards and 2 provincial awards.2.We have the most complete production certificates of oil machines, such as “Design license of pressure vessel”,”Manufacture license of pressure vessel”,”Design license of pressure pipeline”,”Installation,reconstruction and maintenance license of pressure pipeline”, “Manufacture license of organic heat carrier furnace” and installation certification of mechanical and electrical equipment”.3. We are outstanding member enterprise of CCOA (Chinese Cereals and Oils Association), so we produce machines according to standard, and refined oil reaches the best edible oil standard.4.We have strong R & D team, production team and installation team, offer perfect after-sale service, after delivering goods, we will dispatch technicians to instruct installation, commissioning and train your workers to operate machines by yourselves.5.We are provincial enterprise abiding by contracts and keeping promises, we have produced oil machines for 65 years, with rich experience and own brand, so we are responsible for all of our projects, especially for oversea projects.6.Overseas projects: we are establishing every perfect overseas sample project all over the world, such as Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia, Bangladesh, Thailand, the Philippines, Myanmar, Egypt, Sudan, Nigeria, Rwanda, Tanzania, etc.Our company can provide you with 10 to 25 kilograms (test equipment), 2 to 1,000 tons / day of oil refining projects , QiGroup naturally is your preferred partner for different oil quality. in Henan Huatai here are different options, batch chemical refining, semi-continuous physical refining, continuous physical refining program, where Henan Huatai provide you with the design (process, civil, electrical), manufacturing, installation, commissioning, training of technical personnel to the sale a full-service; advanced automatic control system to ensure that the entire production line of automatic, smooth operation; heat saving each segment to ensure that the processing costs to a minimum.

The main refining plant processes: degumming, dehydration, bleaching, deacidification, deodorization, dewaxing, degreasing. Crude oil in squeeze, extraction crude oil can be obtained national quality standards of edible oil through

Service

Pre-sales service1.Quick response2.Detailed quotation3.Professional production and transportation solutionAfter-sales service1.Warranty policy one year from shipment2. We will send you the replacement after received the broken part3. Evaluate the customs risk and choose safest shipping company before shipping.4. Follow status up time by time until the goods arrived.

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.