Showroom Location:Japan

Condition:New

Usage:Cooking oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:95%

Place of Origin:Henan, China

Brand Name:MONA

Voltage:220V/380V

Dimension(L*W*H):2200*1650*1750

Weight:780 KG

Warranty:1 Year

Key Selling Points:Long Service Life

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Gear

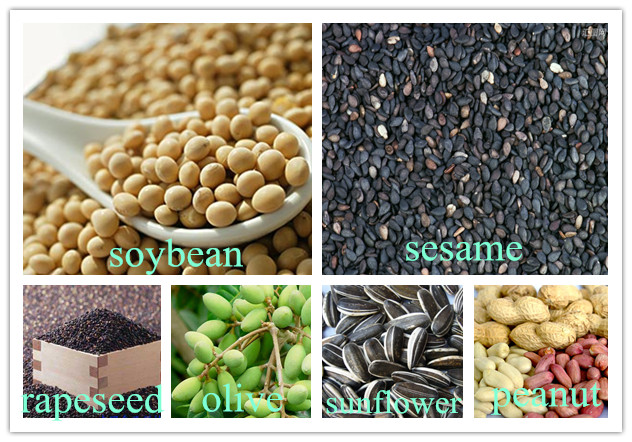

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, Coconut Oil, OLIVE OIL, Palm Oil

Max Capacity:150 kg/h

After-sales Service Provided:Engineers available to service machinery overseas

Name:Oil Presser

Application:Oil Production Line

Material:Stainless Steel 304

Raw material:Soybean Cottonseed rapeseed peanut sesame etc

Capacity:50-1000kg/h

Character:screw oil press,combined oil press

Black Soldier Fly Larvae Oil Expeller Oil Filter Press Machine

rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Working priciple

Working priciple

The technology flow of cooking oil solvent extraction machine:The process is like oil extracted – wet meal desolvation – mixed oil vaporation – stripping by steam – solvent recoveryMaterial embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing ↓Mixed oil→Filter→Negative pressure evaporation → Crude oil ↓Solvent recovery

Advantage

1.This type of automatic screw cold oil making press machine equipment is able to do both cold press and hot press.2.Widely-used:the oil press can be used for more than 20 kinds oil crops.3.Pure oil quality:the vacuum oil filtering is used to remove residue so as to ensure the pure oil quality and meet the standard of health quarantine.4.Save space and labor:an area of 10-20 square meters workshop and 1 to 2 worker can meet the need of production.5. Good quality, durable: made of high-quality materials, high temperature resistance, strong wear resistance.High hardness, high strength, no deformation, long service life. 6. Easy to operate: simple structure, easy to use.One person can complete the entireoperation process .7. Factory direct selling, cost-effective: price concessions, more than one machine, one time squeeze net. 8.Mature technology: mature technology, advanced processing equipment and precise internal structure are adopted. 9. Clean, energy efficient, hygienic: The filtered oil can be used directly and the extracted oil is beautiful.

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

We are a professional oil and grain processing and refining equipment manufacturer in China, which is specialized in the research, design and manufacture of high quality equipment for making edible oils and other auxiliary products.Our company has engineer with more than 30 years of experience in the oil and grain industry and refining and fractionation industry. They are in charge of designing the machines, arranging the product line layouts, installing and adjusting equipment, training staff and working out the best formula for each client.

Service

Pre-sale services:Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment(1) Select equipment model;(2) Design and manufacture products according to clients’ special requirement;(3) Train technical personnel for clients.After-sale services:(1) Assist clients to prepare for first construction scheme;(2) Install and debug the equipment;(3) Examine the equipment regularly;(4)Take initiative to eliminate the troubles rapidly at site;(5)Provide technical exchanging;(6)Provide maintenance for big items

FAQ

Q1 : Which kind of other materials can be processed?All kinds of oil seeds. For example, sunflower seeds, rice bran, corn germ, palm fruit, palm kernel, coconut, peanut, soybean, sesame, cottonseeds, rapeseed, etc.but will have some oil equipment is different,we will design the best palm oil mill for you.Q2 : What’s the capacity of this refined oil mill?Generally, 10-5000 tons per day. We can also manufacture as per customers’ requirements.Q3: What is the Material of this machine?Stainless steel and carbon steel,and we accept customization.Q4 : How long is the warranty?The main parts of the machine come with one year warranty and after the expiration our engineer is available overseas to do the maintenance work.Q5 : Can the machine be installed locally?We can do the turn-key projects or other services according to customers’ requirements, according to this condition, our services include manufacturing, purchasing, transporting, installation, training labors etc.Q6 : How long can we get the goods?We usually delivery in 3-5 working days, we will inform you shipping time based on your seaport.