Applicable Industries:Manufacturing Plant, Food & Beverage Factory

Showroom Location:Spain

Condition:New

Application:Food, Beverage, Chemical, oil

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V 50HZ

Place of Origin:Jiangsu, China

Brand Name:ZT-PACK

Dimension(L*W*H):2440*1150*2300mm

Weight:1850 KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 6000BPH, 2000BPH, 1000BPH

Filling Material:Oil, Lubricant oil

Filling Accuracy:0.2%

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, PLC

Product name:Oil filling machine

Function:Automatic Filler

Bottle type:PET Plastic Bottle Glass Bottle

Capacity:1000-5000BPH

Filling range:100ml-1000ml ; 1-5L

Suitable for:Oil kinds

Control:Servo Motor Control Filling Volume

Advantage:remote control

Filling nozzles:6-16 nozzles can be choose

Packing type:Safety Wooden Case

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Spain

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE/ISO

China Factory Hot Sell Edible oil bottle filling and bottling plant/ oil packaging machine

This oil press machine can be used to make cooking oil with raw materials such as flax seed, peanut, rapeseed, sesame,sunflower, etc.

Raw material

Our machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

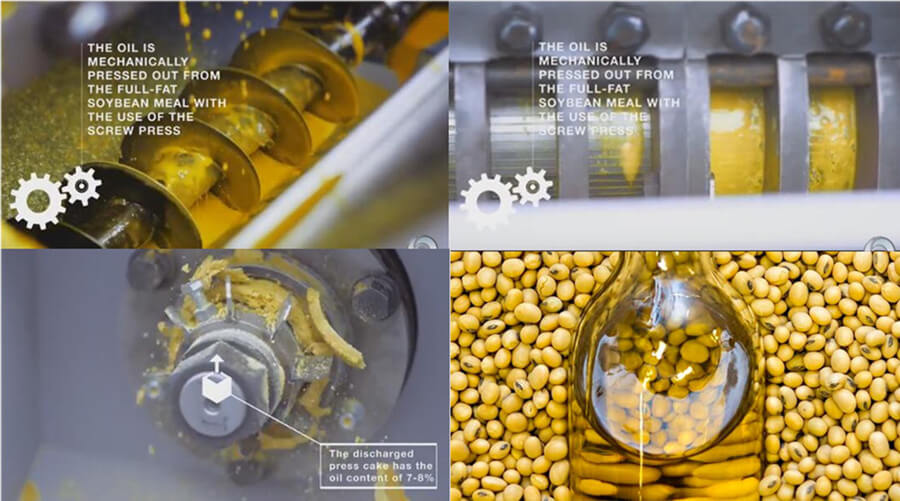

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

This series are equipped with the air-pressure / vacuum filtration system, which make it the press integrated with the filtration, more convenient and automatic;

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We are a professional manufacturer and exporter of mechanical equipment. Our products include edible oil process machines.Our well-equipped facilities,complete after-sale service system and excellent quality control system on all stages of production enable us to satisfy customers from different countries. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Service

1. We can manufacture according to your sample, design and technical indexes;2. We’ll provide you the whole program solution according to ur local customs, oil crops, local market demand;3. After sale, we’ll send our professionals to install and debug the machinery till you have learned all by yourself.

FAQ

1. Q: Which kind of raw materials can be process?A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-3000 tons per day. We can manufacture as customized order. 3.Q: How long is your guarantee ?A: One Year guarantee. We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How about the quality of your products ?A : Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: We will send our engineers to local place to help installing the machine and provide technical guidance.6.Q: What’s the payment terms?A:T/T, Trade Assurance, L/C, Cash etc.