Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Retail, Factory Production workshop

Showroom Location:None

Condition:New

Application:Food, Beverage, Chemical, The function of the production line can be customized

Packaging Type:Bottles, Packaging type can be customized according to the filled product.

Packaging Material:Plastic, Metal, Glass, Packaging type can be customized according to the custom require

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V

Place of Origin:Guangdong, China

Brand Name:zhenxiang smart

Dimension(L*W*H):standard

Weight:standard

Warranty:1 Year

Key Selling Points:Automatic

Machinery Capacity:standard or custom

Filling Material:Other, Oil, Juice, Powder, custom

Filling Accuracy:±1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:can be customized

Product name:Sterile Syringe Injectable Vial Filling Line Systems Equipment

Filling speed:can be customized

Processing Types:Automatic liquid filling production line

Filling head:can be customized

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Online support

Certification:CE,ISO

China Manufacturing High Speed Sterile Syringe Injectable Vial Filling Line Systems Equipment

The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

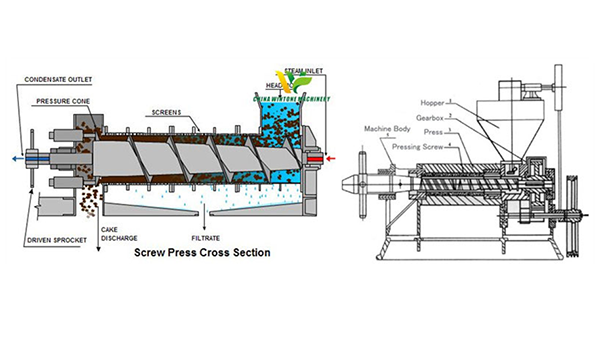

Working priciple

Working priciple

Oil solvent extraction section of vegetable oil production line:Cooking oil solvent extraction machine mainly include oil extraction system, desolventizing and toasting system, evaporation system and condensation system. Main theory is to use appropriate solvent extract oil from oilseeds embryo, then remove the solvent in mixed oil. Our oil extraction process technology to produce mixed oil without any chemical solvents, and can remove the tail gas directly, benefits environment protection.

Advantage

With Our core part the outstanding press chamber and special feeding and transmitting power systems,we realize the advanced multistage press and gradual pushing compress technology, which add more pressure points and strengthen higher press degree of the materials. Our reasonable and unique design of the inner chamber, more advanced compared with the traditional, for example, the cold press machine is main bar Exhaust type leakage design out of the press chamber , but the hot press machine is main the round Exhaust type leakage design. The other difference between the hot and cold press is the feeding and transmitting system, our super design;

Product Specification

Product Specification

| Model | 6YL-60 | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-160 | |

| Dia. | Φ53mm | Φ81mm | φ101mm | φ123mm | φ160mm | |

| Screw speed | 64 r/min | 47r/min | 38r/min | 35r/min | 32r/min | |

| Power | Motor | 1.5-2.2kw | 5.5kw | 7.5kw | 11kw | 22kw |

| Vacuum pump | 0.18kw(VP-1.5) | 0.55kw | 0.75kw | 1.1kw | 1.1kw | |

| Heater | 0.9kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | |

| Capacity | 4.-60kg/h | 80-100kg/h | 150-200kg/h | 250-300kg/h | 500-600kg/h | |

| Weight | 268kg | 880kg | 1250kg | 1500kg | 1800kg | |

| Size(mm) | 1020*720*798 | 1500*1200*1750 | 2000*1300*1850 | 2100*1300*1850 | 2300*1300*1950 |

Company Profile

We offer many different products to cater to different markets all-over the world and to offer a more customized experience and services to individual customers.we own a complete production line for brick machines only as well as block machines. By having great business relationships with location companies, we have ensured a steady supply of materials,which makes short wait times and excellent customer purchasing experience. This makes customers a worry free, “one-stop”shopping location for our customers.

Service

1.We are resonsible for installation and debugging; 2.Instruct operation workers about the operation skills and offer technical service. 3.Quality warranty of the whole set of equipment is offered;

FAQ

Chrome steel or Stainless steelQ6: How long does it take to produce the machine once I place my order ?