Showroom Location:United States, Philippines

Condition:New

Usage:Other

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:98%-100%

Place of Origin:Henan, China

Brand Name:qifeng

Voltage:380V/50HZ

Dimension(L*W*H):1800*1500*2100mm

Weight:1100kg

Warranty:1 Year

Key Selling Points:High-accuracy

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL, Palm Oil

Max Capacity:150 kg/h

After-sales Service Provided:Overseas third-party support available, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Keyword:Mini Oil Expeller

Material:304 Stainless Steel

Feature:High Oil Yield Efficiency

Used for:Pressed Vegetable Oil

Application range:Competitive Mini Oil Press Machine

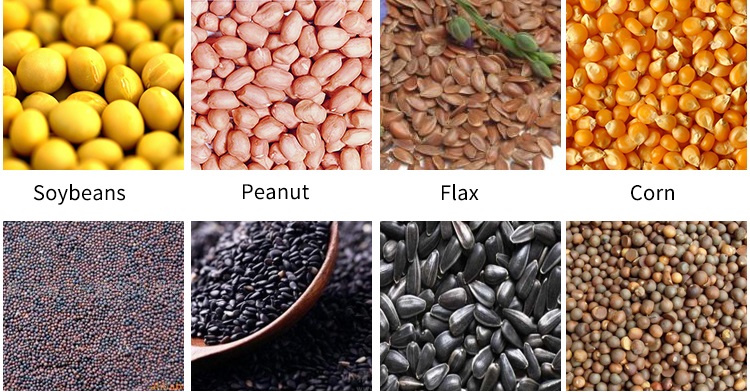

Raw materials suitable:Soybeans Sesame Rapeseed Peanut Seed

Price Level:Castor Oil Processing Equiment

Character:Easy Movable

Capacity:10t/d

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Philippines, Saudi Arabia, Pakistan, Russia

Certification:CE ISO

Cold Press Coconut Oil Production Line, Practical & Reliable

Hot and cold automatic modern oil press is a new product developed by our company. It can press rapeseed, peanuts, tea seed, soybean, sesame, sunflower and other oilseeds, the machine is equipped with micro electric control, infrared heating, filtration system, multistage press.

Raw material

Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm seeds and jatropha seeds.

Working priciple

Working priciple

vegetable oil processing plant/oil extracting machine/oil refinery machinepretreatment/pre-press equipment.

Elevator- shelling – elevator – cleaning -elevator – magnetic drum – flaking- elevator -cooking – pre-press- to extraction work

Advantage

1.This type of automatic screw cold oil making press machine equipment is able to do both cold press and hot press.2.Widely-used:the oil press can be used for more than 20 kinds oil crops.3.Pure oil quality:the vacuum oil filtering is used to remove residue so as to ensure the pure oil quality and meet the standard of health quarantine.4.Save space and labor:an area of 10-20 square meters workshop and 1 to 2 worker can meet the need of production.5. Good quality, durable: made of high-quality materials, high temperature resistance, strong wear resistance.High hardness, high strength, no deformation, long service life. 6. Easy to operate: simple structure, easy to use.One person can complete the entireoperation process .7. Factory direct selling, cost-effective: price concessions, more than one machine, one time squeeze net. 8.Mature technology: mature technology, advanced processing equipment and precise internal structure are adopted. 9. Clean, energy efficient, hygienic: The filtered oil can be used directly and the extracted oil is beautiful.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We have a group of experienced and excellent after-sales service members who provide following up services for worldwide customers.Customers’ need is what we are trying to create. Customer satisfaction is what we are seeking.Over the last couple of decades, Benteng people have created continuously, transcending ourselves and insisting on the concept of “Development is of overriding importance”. Develop the brand with quality. Promote the brand with service. We, Benteng people, are forging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Service

Pre-sale services:1. Providing professional technical support.2. Send the product catalog and instruction manual.3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!4. Personal call or visit are warmly welcome.Sale of services:1. We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.2. We guarantee punctuality, quality and quantities strictly implement the terms of contractAfter-sales service:1. Where to buy our products for 1 years warranty and life long maintenance.2. 24-hours telephone service.3. A large stock of components and parts, easily-worn parts.

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.