Place of Origin:Henan, China

Applicable Industries:Manufacturing Plant

After Warranty Service:Online support

Local Service Location:Uzbekistan

Showroom Location:Uzbekistan

Warranty:1 Year

After-sales Service Provided:Field installation, commissioning and training, Engineers available to service machinery overseas

Application fields:Cannery, Commercial catering, Seasoning plant, Bakery

Type:Grain Processing Equipment

Usage:Maize corn

Name:Corn starch processing line

Color:Customer demand

Raw material:Maize corn

Application:Corn starch making

Final products:Corn starch

Corn Starch Making Machine/Corn Starch Processing Line

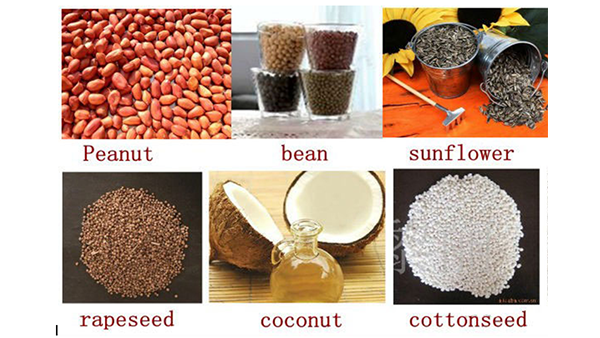

All kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

The Oil press is used to get the edible oil or bio-diesel from vegetable oilseed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, seasame seed, cottonseed, coconut,, etc

Working priciple

Working priciple

Flow Chart of Small scale edible oil refinery plant coconut oil processing machine production line:Crude Oil→ Filter→ Degumming→ Deacidification→ Decoloring→ Deodorizing→ Dewaxing→ Defeat→ First Grade Oil

Advantage

1. Energy Saving:The electric power can be reduced by 40% under the same output. For example, the machine can save 6 kilowatt at an average of one hour. In that case, it could save about 30 RMB per day.2. Labor Saving:60% labor can be saved under the same output. One or two person can organize the production. It can save about 40 RMB of labor cost every day.3. Widely Usage:The machine is multi-function. It can process more than 20 kinds of oil crops, such as, peanut, linseed, sesame,rapeseeds, sunflower, cottonseeds, soybean, etc.4. Oil Pure:Vaccum filter can filter the residue and ensure the oil quality. The oil can meet the standard of health quarantine.5. Small Area Covering: 10 ~ 20 m2can meet the production needs.

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

We are a professional oil and grain processing and refining equipment manufacturer in China, which is specialized in the research, design and manufacture of high quality equipment for making edible oils and other auxiliary products.Our company has engineer with more than 30 years of experience in the oil and grain industry and refining and fractionation industry. They are in charge of designing the machines, arranging the product line layouts, installing and adjusting equipment, training staff and working out the best formula for each client.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.

FAQ

Q1: What is the Material?A1: Stainless steel or carbon steel.Q2: When can I get the price?A2: Within 24 hours, if urgent, please directly call us.Q3: Whether the machine price can be more discount?A3: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our Manager to appropriatelygive you a little discount.Q4: How to ask quotation?A4: Please note us what tpye of raw seeds , and how many tons of raw seeds you want to treat per day, then we will send youquotation as soon as we can.Q5:Does the screw oil press need to be heated?A5:Yes, it does. Preheat with dry oil cake for 30 minutes before feeding seeds normally.Q6: How many people are required to operate this screw oil press?A6: 1-2 people can operate.