After-sales Service Provided:Free spare parts, Overseas Call Centers

Warranty:1 Year

Application:Outdoor, Hotel, Commercial, Household

Power Source:Electric

Type:Electric Contact Grill

Material:Stainless Steel

Non-Stick Material:PTFE

Function:Dismountable Oil Collector, Non-Stick Cooking Surface, temperature control, SMOKELESS

Interchangeable Plates:Sandwich Plates

Lower Grill Size:290*240mm

Upper Grill Size:290*240mm

Power (W):2000

Voltage (V):230

Place of Origin:Zhejiang, China

Brand Name:Sinocraft

Model Number:P47

Products Characteristic:New products

Certification:CB, ce, EMC, Emf, GS, LFGB, RoHS, SASO, UR,attrValueId:43730

Detachable contact grill CE GS RoHS ETL 180 degree 4 Slice Detachable Removable Panini griddle Contact grill

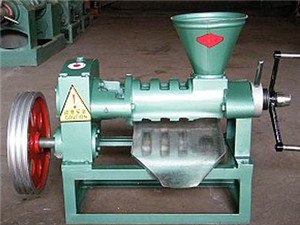

This oil press machine can be used to make cooking oil with raw materials such as flax seed, peanut, rapeseed, sesame,sunflower, etc.

Raw material

Our oil refining line Application:Our refining machine is suitable for refining various of crude oil, vegetable oil, such as palm kernel oil, sunflower seed oil, tea seed oil, peanut oil, soybean oil, corn oil, groundnut oil, rapeseed oil and so on.

Working priciple

Brief processes:Raw material–Magnitic seperating–Metal impurities–Cleaning–Other impurities–Husking–Sunflower seed hull–Cooking–Prepressing–Crude oil–Sunflower seed cake–Extracting Workshop

Advantage

Simple structure, easy to use, adaptable, high oil rate, energy-saving, and low noise. This series of machinery can be widely used to more than 20 kinds of easy and difficult plant oilseeds, such as peanuts, soybeans, rapeseed, cottonseed, sesame, olives, sunflowers, coconut, cocoa, seeds and so on. During pressing, it can be entirely squeezed one time except for some individual varieties.

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

Since 1982 oil press machine1. More than 20 years of foreign trade export experience.2. The professional design R&D team, backed by the university and guided by the market to updated the products.3. Our products exported to the United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Bulgaria and other countries and regions, and got very good reputation.

Service

We always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.