Year:2020

Dimension(L*W*H):5000*5000*2800mm

Weight:1800kgs

Place of Origin:Shandong, China

Voltage:220V/380V

Name:low temperature vacuum frying machine

Application:Crispy okra potato mango apple banana pineapple chips

Function:Frying

Material:SUS304

Capacity:10~300kgs/batch

Feature:Low temperature frying,automatically de-oil, discharge

Frying temperature:80℃-120℃

Vacuum Pressure:-0.1Mpa

Heating Method:Steam heating

Steam consumption:60-80 Kgs/h/batch

Applicable Industries:Hotels, Food & Beverage Factory, Restaurant, Home Use, Food Shop

After Warranty Service:Online support

Local Service Location:None

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:Motor

Condition:New

Type:Fryer

Power:30kw

Certification:ISO 9001

Warranty:18 months

Discount price Frying production line With Best High Quality

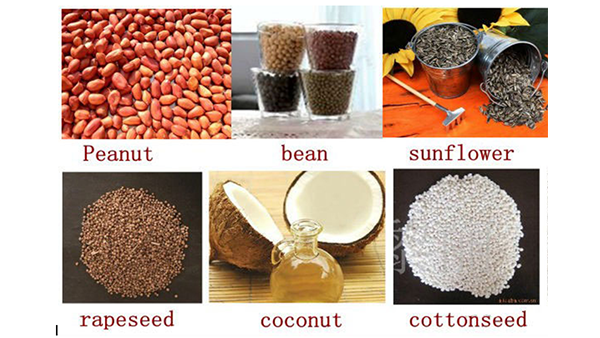

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Raw material

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

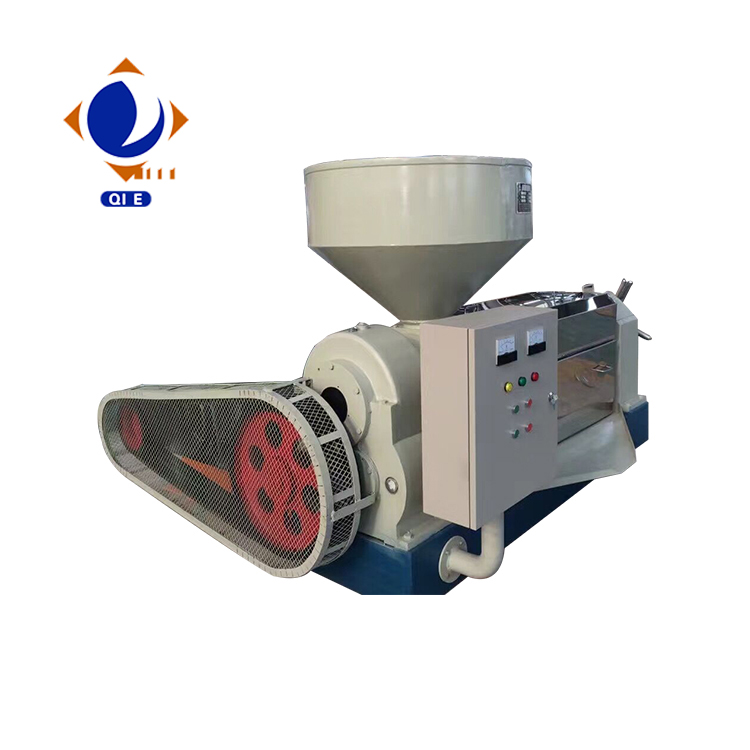

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1 sesame seeds: before entering the press will be the seeds of coffee color is better, (observe the seed color with the hands of Pi Niekai), there are burst phenomenon, stir fry seeds to keep two small fire, the middle of the fire. The pressing temperature 140-150 C, water 1-1.2%, cake for a long strip shape.2. Rapeseed: first with the fire fierce speculation to rapeseed hot, explosion sound so far, then switch to a small fire fried to rapeseed pinch opening was brownish red, pressing rapeseed temperature of 130 DEG C, moisture 1-1.5%, cake thick ness, a small flake, brownish red.3. Peanut: fried seeds before, will be peanuts soaked again, seeds frying in the process, the kernel is fried to eight mature, pinched by hand, achieve benevolence, skin separation, benevolence is a pale yellow, about 130 DEG C temperature, water 1-2%, 0.7 to 1.2 mm thick cake, cake is sliver shaped wrinkles, smooth oil.4 Cottonseed Kernel: before entering the squeeze oil to light yellow, temperature 120-130 C, water 1.5-2.5%, cake thickness 1-1.5 (south, north of the water is not a, proper control of water). 80-100 C, water 6-8%, every time the cake thickness 1.5-2mm, second times the cake thickness 0.7mm, but the two times the yield will be decreased.5 sunflower: raw material to be selected, the raw water before the seed soaking, medium heat and stir fry seeds, the pressing temperature 120-130 degrees Celsius, water 1-2%.6. Soybean: pressing before fry to burst edible, 120-130 degrees Celsius temperature, moisture 1.5-2.8%, cake thickness 0.7mm, dry again, but again dry cake material too coke, the protein loss is larger. Can be used to process two times dry, soybean fry six or seven mature, pressing temperature

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

Our company is a group company integrating food machinery,animal husbandry machinery,oil machinery and environmental protection machinery. Our products are exported to Nigeria, Mongolia, Cameroon, Uzbekistan, Egypt, South Africa, Korean, Spain, America, Bangladesh and so on. We have served more than 20countries and nearly 5,000 clients around the world. Our services received positive review by our customers. Due to the good quality and high cost performance, our machinery has been hot sale all over the world, Our service tenet is: do a leader of the industry, do a creator of the industry, do a service of the industry, Look forward to making progress together with you!

Service

Pre-sale services:Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment(1) Select equipment model;(2) Design and manufacture products according to clients’ special requirement;(3) Train technical personnel for clients.After-sale services:(1) Assist clients to prepare for first construction scheme;(2) Install and debug the equipment;(3) Examine the equipment regularly;(4)Take initiative to eliminate the troubles rapidly at site;(5)Provide technical exchanging;(6)Provide maintenance for big items

FAQ

What does need from me to quote a price?1.Raw material2.Production capacity per batchWhat is the oil yield?The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil. The oil residual of our small hydraulic oil press machine, cold press virgin coconut/avocado/olive oil extraction extracting machine is 1%Can I use the machine to extract several kinds of raw materials?Yes,of course. such as sesame, sunflwoer seeds, soybean, peanunt, coconut, etcCan I do extraction test with my own raw material?Yes,of course.We can do extraction test and send you videos and test report for your Reference.What is your material of your machine?Carbon steel or Stainless steel(Standard type is SUS304,it can be customized according to your request)How long does it take to produce the machine once I place my order ?Usually the delivery time is 5 working days after prepayment received.What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.Do you have machines in stock?Yes.