Showroom Location:Egypt, Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Tajikistan, Japan, Malaysia, Australia

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:filter press cloth yarn material, filter press cloth yarn knitting method, filter press cloth micron rating

Condition:New

Automatic Grade:Automatic

Place of Origin:Zhejiang, China

Brand Name:Leo Filter Press

Voltage:refer to filter press

Power:refer to filter press

Weight:refer filter cloth material

Dimension(L*W*H):upto filter press plate

Warranty:0

filter press cloth:different filter press specifciation

filter press cloth specification:different filter press cloth

filter press cloth micron rating:various for filtering mesh

filter press cloth size:filter press plate from 400mm to 2000mm

filter press cloth material:various type

filter press filtering size:different filter cloth mcron rating

filter press cloth supplier:Leo Filter Press

filter cloth material:different knitting yarn,polypropylene,nylon,PE,PA

filter press cloth thickness:different filter cloth thickness

filter press cloth quantity:the same as the filter press cloth quantity

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Local Service Location:Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine

After-sales Service Provided:Online support

Certification:CE,ISO

Filter Press Cloth for Different Size Cloth Replacement in Various Material and Filtering Micron Mesh from Leo Filter Press

soybeans, perilla seed, shelled hemp, flax seed, flax seed,camellia seed, walnut, black sesame, rapeseed, sesame, sunflower seed.Sunflower seeds, almonds, red / white pepper seeds, peanut, pumpkin seeds, pine nut, coconut meat.

Raw material

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more.

Working priciple

Working priciple

The Motor offers power to Hydraulic Box to squeeze the kinds of materials up and down in the kettle, through the Control System control the working pressure and temperature, stop working when the pressure over the set point(60mpa) automatically, when the pressure reduces to about 50mpa the machine will work again, this cyclic processing can squeeze materials roundly and improve the oil yield.

Advantage

(1)The lubrication should be checked after every 50 hours of operation. The oil cup on the gearbox should not be short of oil. The screw shaft should be adjusted from the adjustment screw hole to the oil in the screw hole. Dry grinding is strictly prohibited.(2)The parts of the oil should be protected from dust and other impurities. The quality of the oil in the gearbox should be checked once a year. If it is found to be deteriorated, all oil should be replaced.(3) When the crushing amount is reduced and the cake or oil is not normal, the screw shaft should be taken out to check the wear of the screw, the strip and the cake ring, and the worn parts should be replaced in time.

Product Specification

Product Specification

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

Company Profile

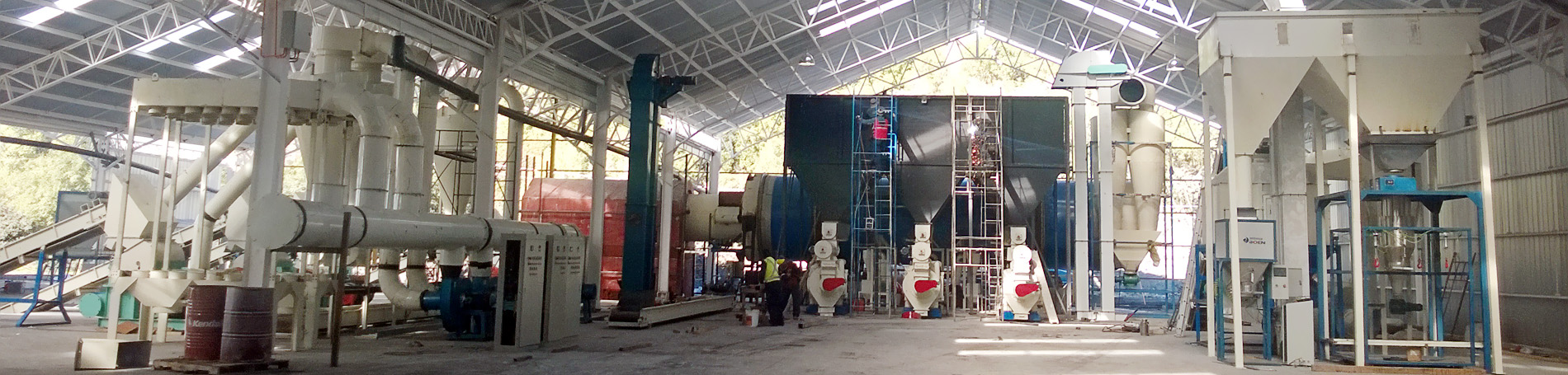

We are a large scale oil machinery manufacturer integrating research, development, design, manufacture and installation. Established in 1982, we have 210 senior engineering technicians among 580 staff, with investment amount of USD60,000.000, covering 10 hectares of factory area, 8 production workshops, 2 machining workshops,12 installation departments.We have 202 sets of automatic processing equipment, annual processing capacity is more than 3000 sets.Our oil machines sell well in more than 30 provinces, cities and districts, and exported to Kazakhstan, Tajikistan, Uzbekistan, Russia, Bolivia, Peru, Egypt, Bangladesh, Myanmar, Malaysia, Indonesia,Solomon Islands, Sudan, Rwanda and other countries and regions, and now we have developed into a major oil machinery manufacturing base in China.

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

1.Q:Can you guarantee the quality of your machine?A:We are a professional manufacturer with strict quality requirementsoil press machine2.Q:Does your factory accept customization?A:As a professional manufacturer, we can do almost any kind of customization.3.Q:What’s the delivery time?A:Generally after paying the final payment 3-5 days.4.Q:How long can I receive the goods after placing the order?A:7-15 days if there is no unexpected.5.Q:What should I do if the oil making machine will not be installed?A:Don’t worry, we have a perfect after-sales service system and can provide you video supports for free.6.Q:What’s your terms of payment?A:50% in advance, balance before shipment.