Showroom Location:None

Condition:New

Usage:mini oil refinery plant

Type:mini oil refinery plant

Automatic Grade:Automatic

Production Capacity:2500Kg/day

Place of Origin:China

Brand Name:Kinetic

Voltage:380V/50HZ

Dimension(L*W*H):3000*830*1700mm

Weight:350kg

Warranty:1 Year, One Year

Key Selling Points:High Productivity

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

After-sales Service Provided:Engineers available to service machinery overseas, Field installation, commissioning and training, Video technical support, Online support

Product name:mini oil refinery machine

Function:Degumming and deacidification and decolorization

Application:Oil Production Line

Material:Stainless Steel

Capacity:500-2500kg/day

Price:factory price

Name:mini oil refinery machine

Model Number:JLJ-75B

After Warranty Service:Online support

Local Service Location:None

Certification:CE ISO

Flaxseed korea mini Double tanks crude black oil gas refinery castor oil refining mill Rice bran oil pressing machinery

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

Raw material

Automatic Cold Pressed Oil Extraction Castor Walnut Press Palm Refining Groundnut Peanut Oil Making Oil Expeller Machine is Suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame, sesame seed, tea seed, walnut, olive, corn germ, rice bran, tea seed, safflower seed, seeds of hippophae rhamnoides and so on.

Working priciple

Working priciple

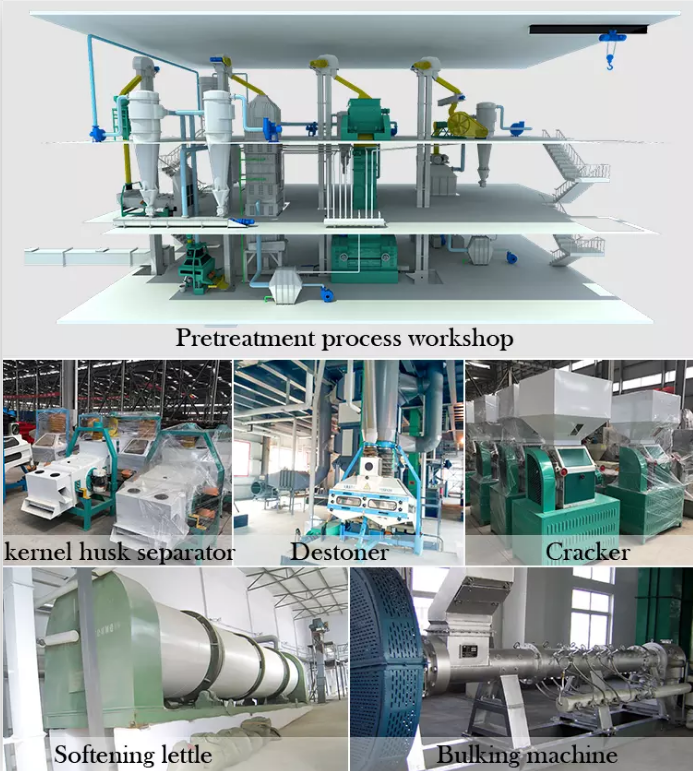

Magnitic seperating:In order to remove the metal impurities, so that can prevent damaging the equipment and occuring safety accidents.Cleaning: To remove the imourities in the raw matrial such as soil, stem and leaf, hull and moldy seeds.Husking: In order to improve the oil yielding rate and the quality of crude oil and meal, reduce the wear to the equipment, the hull must be removed.Cooking: This processing can improve prepressing oil yielding rate and the quality of the cake, adjust the moisture, temperature and plasticity of the flake.Prepressing:To squeeze out part of the oil in the raw material, and improve extracting effect.

Advantage

* Wide application for a great number of vegetable plant seed.Small investment, fewer land space, but with the complete function of oil processing to get higher oil yield.Easier to operate, easier to install and commissioning.Healthy cooking oil can be obtained by mechanical pressingWe pursue the quality of the machines, and each machine will undergo a complete inspection before shipmentThe details and accessories of the machine are also our focus. We guarantee to supply machine accessories at low prices all year round.

Product Specification

Product Specification

| Usage | sunflower oil production line |

| Type | Cold & Hot Pressing Machine |

| Automatic Grade | Automatic |

| Place of Origin | China |

| Voltage | 220V/380V/440V |

| Oil type | Sunflower Seed Oil |

| Max Capacity | 3000tpd |

| Product name | Vegetable Oil Sunflower Cooking Oil Production Line Of Edible Oil |

| Raw material | Sunflower seeds |

| Factory visit | welcome |

Company Profile

We have 8 standard production workshops, 2 machining workshops and 12 engineering installation teams. Huatai Machinery Company has 120 sets of processing equipment, including more than 80 sets of lathes, planers, milling machines and drilling machines,over 10 sets of shears forming equipment, 6 sets of submerged arc automatic welding machines, more than 80 sets of welding machines , and also equipped with various auxiliary equipment and detection equipment.Our oil making machine sells well in more than 30 provinces,cities and districts, and are exported to Russia,Malaysia,Kazakhstan,Thailand, Indonesia,Egypt, Philippines Russia,Kazakhstan,Uzbekistan,Tajikistan, Bolivia, Peru, Indonesia and other countries & regions,and now we have developed into a major oil machinery manufacturing.

Service

1.We are resonsible for installation and debugging; 2.Instruct operation workers about the operation skills and offer technical service. 3.Quality warranty of the whole set of equipment is offered;

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.