Brand Name:LONKIA

Power Source:Electric

Warranty:3 years

Dimension(L*W*H):65X80X95 cm

Power:7.5kw

After-sales Service Provided:Field installation, commissioning and training

Weight:100kgs

Condition:New

Voltage:220v/380v

Applicable Industries:Garment Shops, Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Energy & Mining, Food & Beverage Shops

Key Selling Points:High Productivity

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:United States, Italy, Kenya, UAE

Showroom Location:United States, Italy, Kenya, UAE

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:3 years

Core Components:Pressure vessel, Gear, Motor

Product name:Chicken Deep Fryer Machine

Application:Fry Snacks

Keyword:Multi-functional Deep Fryer

Feature:Save Oil

Usage:Frying Processing Line

Advantage:High Efficient Low Running Cost

Function:Multifunction

Material:SUS304 Stainless Steel

Color:Silver White

Capacity:100-1000kg/h

Certification:CE, ISO

Fryer Machine banana Fruit Fryer Industrial Commercial Factory Price Potato Chips Continuous Fryer

Vegetable oil making machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

Screw press is suitable for pressing rapeseed, peanut kernel, soybean, olive, walnut kernel, corn germ, rice bran, tea seed, safflower seed, sea buckthorn seed, neem seed, rubber seed, pepper seed, tomato seed, watermelon Vegetable oils such as seeds, grape seeds, flaxseed, evening primrose, pepper seeds, castor beans, citrus seeds, cocoa beans, coffee beans, perilla, almonds, peach kernels, and rose hips.

Working priciple

Working priciple

1.Material enters the extruding chamber from the hopper.2.There is quite strong friction among press screw, chamber and the oil materials.3.Root diameter of the pressing screw carries larger from one end to the other.4.Last,helping protein change property, damage colloid, increase plasticity, decrease oil’s elasticity, resulting in high oil.

Advantage

Advantages of cooking oil making machineThe whole extraction workshop is selected on the base of safety,reliable,energy-saving, less fault,easy maintenace,and long using life,adopting world advanced technology and equipment to achieve the beat process effects.Features of cooking oil processing machine:Applicable for various kinds of low oil content raw material,like rice bran, rapeseed, cotton, corn germ etc cakes for max oil yield. After extracting ,the resid oil is lower than 1%.

Product Specification

Product Specification

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 |

| Speed of press screw(r/min) | 30-40 | 30-40 | 30-40 | 28-40 | 28-40 |

| Boundary dimension(mm) | 1650*1150*1750 | 900*1300*1850 | 2200*1650*2100 | 2300*1600*2100 | 2400*1700*2100 |

| Capacity(kg/h) | 80-150 | 150-250 | 200-300 | 300-400 | 400-600 |

| Heater(kw) | 2 | 3 | 3.3 | 3.8 | 4 |

| Residual oil rate | 6-7% | 6-7% | 6-7% | 6-7% | 6-7% |

| Weight(kg) | 680 | 870 | 1280 | 1420 | 1600 |

| Power(KW) | 5.5 | 7.5 | 11 | 15 | 380V, 18.5 KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW |

| Product condition | 1 Staff ,plant 20-30㎡ | 1-2 Staff ,plant 30-50㎡ | 2 Staff , plant 40-50㎡ |

2-3 Staff ,plant 40-60㎡ | 2-3 Staff ,plant 60-80㎡ |

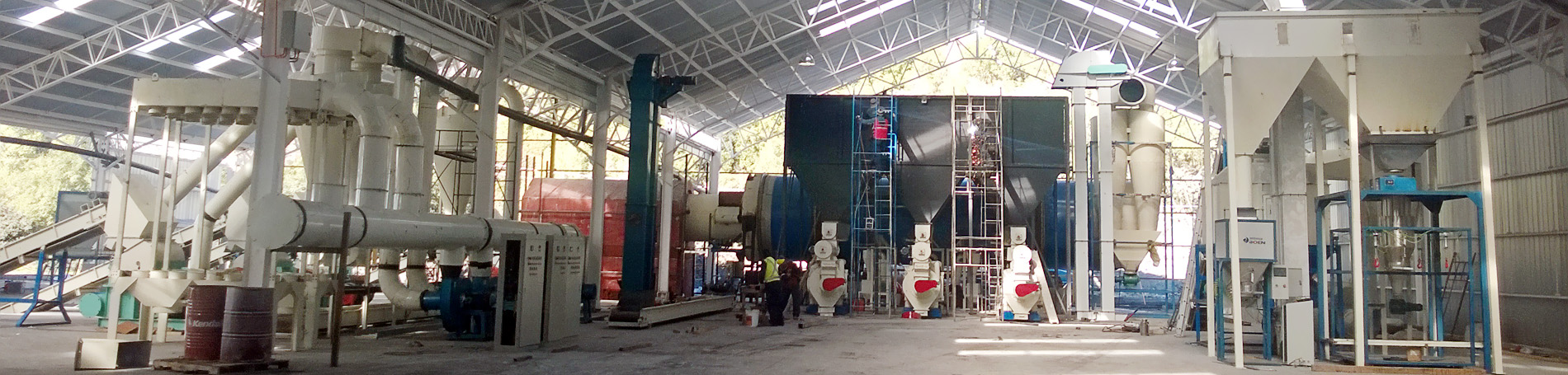

Company Profile

We are a professional oil and grain processing and refining equipment manufacturer in China, which is specialized in the research, design and manufacture of high quality equipment for making edible oils and other auxiliary products.Our company has engineer with more than 30 years of experience in the oil and grain industry and refining and fractionation industry. They are in charge of designing the machines, arranging the product line layouts, installing and adjusting equipment, training staff and working out the best formula for each client.

Service

1, 1 year free warranty. Whole lifetime maintenance.2, Supplying wearing parts all year around.3, Supporting technical solutions at any time.4, Helping design and plan the oil plant’s construction.5, Providing installation video.6, Tried orders are available.7, Developing agents with good policies around worldwide.Service before sale1.One-on-one exclusive customer service staff, 24 hours online.2.Inquiry, email, message will be replied at first time.3.Supply professional technical parameters, video picture sharing, project design.Service on sale1.Ensure customer payment security.2.Ensure the customer’s price is stable and reasonable.3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good. Service after sale1.Arrange high-efficiency delivery and safe transport.2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.

FAQ

1. Q: Which kind of raw materials can be process?A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-3000 tons per day. We can manufacture as customized order. 3.Q: How long is your guarantee ?A: One Year guarantee. We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How about the quality of your products ?A : Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: We will send our engineers to local place to help installing the machine and provide technical guidance.6.Q: What’s the payment terms?A:T/T, Trade Assurance, L/C, Cash etc.