Applicable Industries:Food & Beverage Factory, Retail, Other

Showroom Location:None

Condition:New

Application:Beverage, Chemical, Commodity, Food, Medical

Packaging Type:Cartons

Packaging Material:Paper

Automatic Grade:Automatic

Driven Type:Pneumatic

Voltage:220v/110v

Place of Origin:Zhejiang, China

Brand Name:SAN YING

Dimension(L*W*H):1200*300*700

Weight:45 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:8000BPH

Filling Material:Beer, Other, Milk, Water, Oil, Juice

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Other, Gear

After-sales Service Provided:Engineers available to service machinery overseas

Name:Double head paste filling machine

Air pressure:0.4~0.6mpa

Filling error:±0.5%

Filling range:5-100ml 10-300ml 100-1000ml 500-2500ml 1000-5000ml

Machine weight:40Kg 45Kg 50Kg 60Kg 70 Kg\t80kg

Filling speed:10-60times/min

Hopper volume:50L

Package size:Please inquire

G2WG Double head paste filling machine(5-100ml)

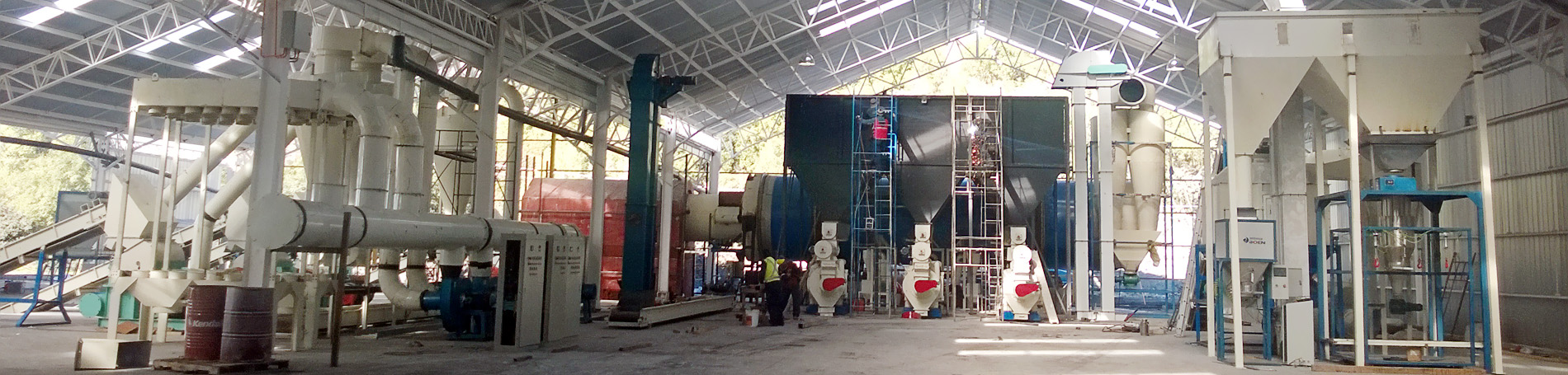

various raw materials, as ground nuts, bean, rape and cotton seeds, sesame, olive, sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

Raw material

the plant is suitable for Soybeans, peanuts, corn, flax, linseed, tea seed(camellia seed), sesame,walnuts, rapeseed, grape seed,castor, sunflower, cottonseed etc.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

1.304/316 SUS 2.Customized crude oil refining line capacity. We customize plant as per your requirement for the capacity.3. Flexible usage. The crude oil refining line can work independently or together with whole oil production line.4. Two sets centrifugal machine make sure all continuous production , degumming result is very good.5.The refined oil has high quality and is good for long time storage.6. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

Since 1982 oil press machine1. More than 20 years of foreign trade export experience.2. The professional design R&D team, backed by the university and guided by the market to updated the products.3. Our products exported to the United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Bulgaria and other countries and regions, and got very good reputation.

Service

1.we can free offer complete set 3-500 tons/24 hour cooking oil plant project offer . 2.we can do turn-key project, including design,installation, test and training 3.One-year free spare parts. 4.One-year quality gurantee. 5.Lifetime service.

FAQ

QHow can I get the sample to check your quality?AAfter price confirmation, you can require for samples to check our product’s quality.QWhat can I get the price?AWe usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.QWhat is your term of delivery?AWe accept EXW, FOB Shanghai or FOB Qingdao. You can choosethe one which is the most convenient or cost effective for you.QWhat about the lead time for the production?AHonestly, it depends on the order quantity and the season you place the order. In common 7~15 days.