Showroom Location:None

Video outgoing-inspection:Not Available

Machinery Test Report:Not Available

Marketing Type:New Product 2021

Warranty of core components:1 Year

Core Components:Filter Element

Condition:New

Place of Origin:China

Brand Name:aistar

Weight:0.45

Dimension(L*W*H):97*97*140mm

Warranty:1 Year

Application:Oil Filtration

Product name:Gilbarco Oil filter

Filter material:HV Filter Paper

Filter Type:impregnated cellulose media

Model:R18189-30

Material:Aluminum

Working medium:Oil

Structure:Fuel Oil Filter Cartridge

Usage:General Hydraulic Oil System

After Warranty Service:No service

Local Service Location:None

After-sales Service Provided:Video technical support,attrValueId:190000884

Gilbarco Oil filter machine for fuel dispenser of Tokheim bump

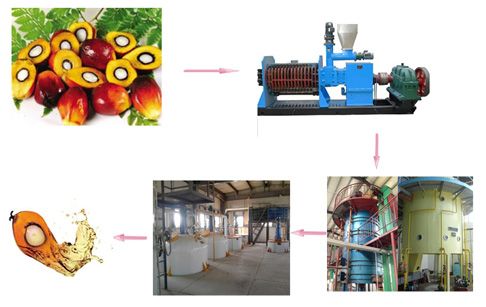

Our machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

Processing materials: sunflower seed, peanut, mustard, almond, black sesame, tea seed, cottonseed, etc

Working priciple

Working priciple

Main Parts Of The Automatic Oil Press Machine:1.screw shaft2.feeder3.pressing cage4.oil pan5.squeezing bolt6.vacuum oil filter system7.electric control system8.heating ring

Advantage

* High hardness and strength, good abrasion resistance and long using life.* vegetable oil seeds, corn ,sunflower ,soybeans, peanuts, cotton seeds, sesame seeds, palm kernel,coconut etc* Compact structure, stable function, simple maintenance.* High oil output rate* The quality of oil is pure.* Efficient oil producing, easy operating, high automatic.

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

We have abundant experience in product research, strong technical force, sophisticated production, and specializing in production of oil press machine, the main products are automatic Hydraulic oil press, and related products: wok, vibrating screen, peanut sheller, sesame feeding machine, oil filter machine, spiral hoist, automatic seed feeding machine. Our hydraulic oil press is suitable for a variety of oil crops(sesame, peanut, walnut, mustard, olive, sunflower and more), all parts of the machine are made up of premium alloy steel and excellent craftsmanship, won an excellent reputation and satisfaction among customers.Welcome customers from worldwide come for a visit to our factory!

Service

1, 1 year free warranty. Whole lifetime maintenance.2, Supplying wearing parts all year around.3, Supporting technical solutions at any time.4, Helping design and plan the oil plant’s construction.5, Providing installation video.6, Tried orders are available.7, Developing agents with good policies around worldwide.Service before sale1.One-on-one exclusive customer service staff, 24 hours online.2.Inquiry, email, message will be replied at first time.3.Supply professional technical parameters, video picture sharing, project design.Service on sale1.Ensure customer payment security.2.Ensure the customer’s price is stable and reasonable.3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good. Service after sale1.Arrange high-efficiency delivery and safe transport.2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.

FAQ

a discount.Q8: Do you have machines in stock?Yes, we have some models oil press in stock.Q9: How will my order be packed, can you provide the installation service?Packed in plywood case. We will send English manual. If the customer need, we will send one engineer for assembling and training for workers.