Showroom Location:Canada, United Kingdom, United States, Saudi Arabia, Kenya, Argentina, UAE

Condition:New

Usage:sunflower oil,Olive oil, palm oil ,peanut oil,sesame oil,soybean oil ,

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:98%-100%

Place of Origin:Shanghai, China

Brand Name:GOLDSEN

Voltage:220V/380V

Dimension(L*W*H):1050*800*1400mm

Weight:330 KG

Warranty:2 years, One Year

Key Selling Points:High Productivity

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Bearing

Oil type:Flax Seed Oil, Soybean Oil, SESAME OIL, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil

Max Capacity:1000 kg/h

Capacity:100-110Kg/Hour

Material:stainless steel and carbon steel

Usage range:sunflower oil,Olive oil, palm oil ,peanut oil,sesame oil,soybean oil ,

Oil-content rate:less than 8%

Wearing parts:Loops\\spirals\\bars

HS CODE:8479200000

Name:sesame/olive/peanut/soybeans oil press machine

Certification:ISO CE

ground nut frankincense basil peanut sunflower seed castor sesame palm kernel oil extraction machine

Crushing peanuts,sesame, pumpkin seeds, linseed, mountain seed, cocoa bean, coffee bean, pepper seeds, walnuts, tea seed, castor, camellia, pumpkin seeds, nuts, olive, black seed, walnut, animal oil fat, almond and other oil crops.

Raw material

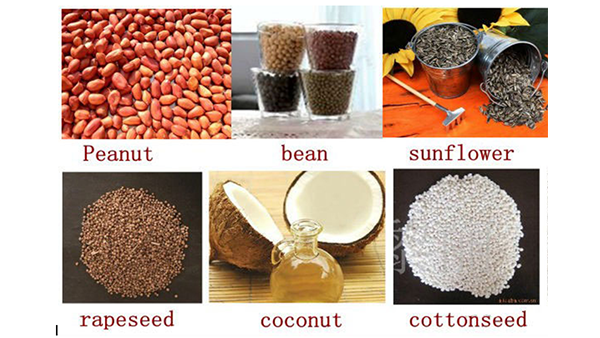

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Processing capacity | 3.5T–11T Per day. |

| Residue oil of the cake | ≤7.8% |

| Temperature control power | 3.0kw |

| Main electromotor power | 11kw |

| Spiral axes rotate speed | 32-40 |

| Weight | 1000kg-1400kg |

Company Profile

our company as manufactures for oil press machine,we have more than 20 years of experience, our products all achieved patent certificates, and our company has many times achieved the title of honor: ” Observe Contract and Keep Promise” ” Quality,Trustworthy Product” “Good After-sales Service Reputation”, etc.it developed from a pure equipment manufacturers to a high-tech enterprises includes research&development, manufacturing, marketing, service and e-commerce. Our group is composed of highly dedicated employee from around the world, ensuring the success of customers and close cooperation. We are committed to mining to provide customers with world-class products and services. “Customers Trust, Preferred Supplier” is the persistent pursuit of our people.

Service

Pre-sale service1. Offer the professional solution and design drawing.2. Accept the customized model machine3. Accpect to visit factory4. Ffree testing5. Offer professional quotation6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service.

FAQ

1.Ask:What is this Automatic oil press machine application?Answer:suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame, sesame seed, tea seed, walnut, olive, corn germ, rice bran, tea seed, safflower seed, seeds of hippophae rhamnoides, neem seed, rubber seed, pepper seeds, tomato seeds, watermelon seeds, grape seeds, flax seed, evening primrose, pepper seeds, Castor seeds, Citrus Seeds, beans, beans, almonds, Coffee perilla, peach, rose fruit oil plants.2.Ask:The features of this automatic oil press machine?Answer:Oil Press Machine temperature control, vacuum filtration, three squeeze, high oil, pure color and so on.