Model Number:TQ-300

Application:Liquid

Condition:New

Warranty:1 Year

Applicable Industries:Food & Beverage Factory

Key Selling Points:Competitive Price

Weight (KG):390

Showroom Location:Canada, India, Indonesia, Australia, Germany, Turkey, Uzbekistan, Italy, United Kingdom, Thailand, Viet Nam

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:Pressure vessel

Material:SUS304/SUS316L

Function:Extracting Concentrating

Usage:Liquid, hemp, herb, essential oil, plant oil extraction

Capacity:100~5000L, Customized

Heating source:Steam / electric

Extraction Type:Liquid extraction

Accessories:Agitator, Condenser, Defoamer, Bag Filter etc.

Sealing Mode:Mechanical Seal

Keywords:Herb oil extractor machine

Type:EXTRACTOR

After-sales Service Provided:Field maintenance and repair service, Online support, Free spare parts, Video technical support, Field installation, commissioning and training

After Warranty Service:Spare parts, Online support, Video technical support, Field maintenance and repair service

Local Service Location:Italy, Thailand, Turkey, Uzbekistan, India, Indonesia, Viet Nam, Germany, Canada, Australia, United Kingdom,attrValueId:3326219

Herb oil extractor machine

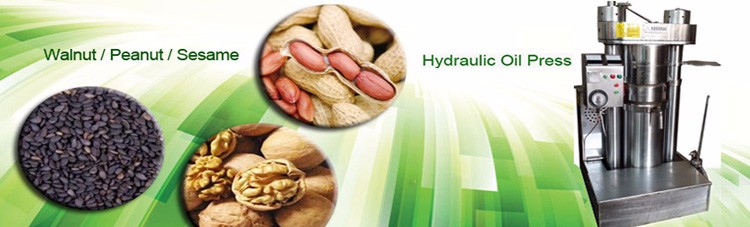

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Raw material

The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Working priciple

Working priciple

Palm oil is a tropical woody vegetable oil. It is the largest variety of vegetable oil in the world in terms of production, consumption and international trade. Because of the particularity of oil palm fruit structure, its oil-making technology and equipment are quite different from other oils. The oil-making process of palm oil mainly includes the following parts:sterilization and fermentation, threshing, mashing and cooking, pressing oil, crude oil purification, oil storage, separation of kernels and fibrous substances, separation of kernels and kernels, and storage of kernels.

Advantage

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

We are a professional manufacturer of oil covering an area of more than 20,000 square meters, with a standardized heavy industrial plant, is a collection of r & d production, sales as one of the powerful enterprises.

Service

Acceptance standardUnless stipulated in the technical documents accordingly, technology acceptance standards of designed main parts are in accordance with relevant state departments issued current relevant standards. providing main parts technology acceptance standard of technical design. Technical serviceDuring rice mill machinery installation, We cooperate with buyer for technological improvement to reach desired results. We explains rice mill machinery performance, structure and operation to buyer related people for free.Quality guaranteed We makes sure our rice mill machinery achieve promised performance with correct installation, commissioning, normal operation and maintenance. In warranty period, for quality problem, we repair and replace defective parts for free(except quick-wear part).

FAQ

Usually the delivery time is 3-15 working days after prepayment received.Q7: What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you