Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco

Packaging Type:CANS, Bottles, Capsule

Packaging Material:Plastic, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:110V, 220V

Place of Origin:Guangdong, China

Dimension(L*W*H):2000*1000*2100mm

Weight:500 KG

Warranty:5 years

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 2000BPH

Filling Material:Beer, Milk, Water, Oil, Juice, Powder

Filling Accuracy:±1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pump, PLC, Motor, Pressure vessel, Pump, PLC

Product name:Liquid filling machine

Processing Types:Filling Capping Labeling

Control:PLC+ Touch Screen

Material:SS304/316

Filling material:honey/jam/tomato paste/shampoo/oil

Filling volume:50-5000ml(customized)

Filling speed:100-3000BPM(customized)

Filling head:2/4/6/8/10(customized)

Air pressure:0.4-0.6 MPa

High-Efficiency Long Service Life Stainless Steel Automatic 4 Nozzle Paste Sealing Filling Machine

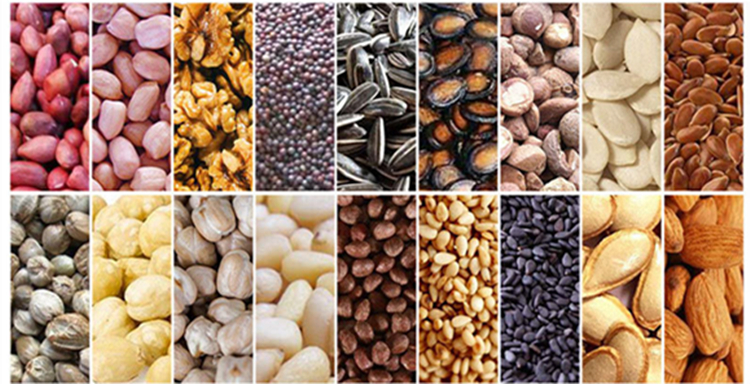

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Raw material

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

Working priciple

Working priciple

Main Process of cooking oil refinery machine:1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.3. Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Advantage

1.Large processing capacity2.Combined Steaming & Cooking3.Lower energy consumption4.Automatic and Continuous Operation5.Flexible production6.Higher quality oil and cake & Steady oil yield7.Perfect Construction, Simple Control and Durable service

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

We are one leading producer of oil equipment in China. We are specialized in vegetable oil production line for 40 years. Our company have special engineers for cooking oil making machine. They are reseaching and developing the technology.We have advanced processing vegetable oil production line and scientific management system. The vegetable oil production line have gained many achievements and awards. Our machines have been exported to Congo, Urganda, Uzbekistan, Kazakhstan, Cananda, Chile, Argentina, Ethiopia, Zambia, Nigeria, Russia, Turkey and so on.

Service

1.We are resonsible for installation and debugging; 2.Instruct operation workers about the operation skills and offer technical service. 3.Quality warranty of the whole set of equipment is offered;

FAQ

What does need from me to quote a price?1.Raw material2.Production capacity per batchWhat is the oil yield?The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil. The oil residual of our small hydraulic oil press machine, cold press virgin coconut/avocado/olive oil extraction extracting machine is 1%Can I use the machine to extract several kinds of raw materials?Yes,of course. such as sesame, sunflwoer seeds, soybean, peanunt, coconut, etcCan I do extraction test with my own raw material?Yes,of course.We can do extraction test and send you videos and test report for your Reference.What is your material of your machine?Carbon steel or Stainless steel(Standard type is SUS304,it can be customized according to your request)How long does it take to produce the machine once I place my order ?Usually the delivery time is 5 working days after prepayment received.What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you a discount.Do you have machines in stock?Yes.