Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Showroom Location:Egypt, Canada, Russia, Spain, Thailand, Morocco, UAE, Colombia, Romania, Malaysia, Australia

Condition:New

Application:Beverage, Chemical, Food, Other, Commodity, Machinery & Hardware, APPAREL, Textiles, For Any Liquid or semi-liquid

Packaging Type:Barrel, Bottles, CANS, case, Other

Packaging Material:Glass, Metal, Wood, Plastic, Other

Automatic Grade:Automatic

Driven Type:Pneumatic

Voltage:220V/110V 50-60Hz

Place of Origin:Shanghai, China

Brand Name:YUGANG MACHINE

Dimension(L*W*H):customaize

Weight:850 KG

Warranty:1 Year, one year

Key Selling Points:Competitive Price

Machinery Capacity:2000BPH, 1000BPH

Filling Material:Beer, Other, Oil, Juice

Filling Accuracy:+-0.5%, +-0.5%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Other, PLC, Gear, Engine

Machine Name:Automatic engine oil lube oil filling capping labeling machine

Machine Made:Stainless steel 304

Filling Range:800-5000ml

PLC controlled:Adopt SIMENS, MITSUBISHI

Pueumatic parts:Authentic AIRTAC (SMC,FESTO can be choose)

Use life:More than 8 years

Service:Supply technical supporting and spare parts anytime

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Egypt, Canada, Russia, Spain, Australia, Morocco, UAE, Colombia, Romania

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE/ISO

high quality Automatic motorcycle engine oil filling machinery production line

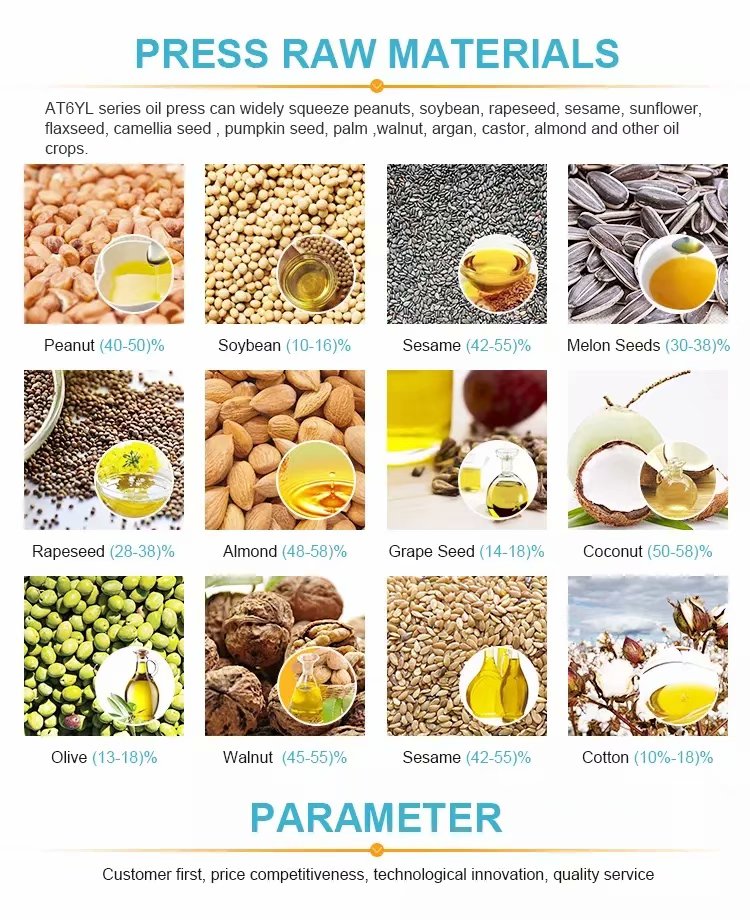

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Raw material

Screw press is suitable for pressing rapeseed, peanut kernel, soybean, olive, walnut kernel, corn germ, rice bran, tea seed, safflower seed, sea buckthorn seed, neem seed, rubber seed, pepper seed, tomato seed, watermelon Vegetable oils such as seeds, grape seeds, flaxseed, evening primrose, pepper seeds, castor beans, citrus seeds, cocoa beans, coffee beans, perilla, almonds, peach kernels, and rose hips.

Working priciple

Working priciple

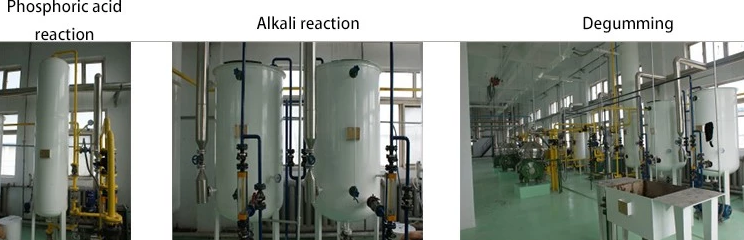

Screw expeller pressing is to extract the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of screw oil expeller, they have similar theories in screw expeller pressing. Because the screw type seed oil expeller is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process.

Advantage

1.Large processing capacity2.Combined Steaming & Cooking3.Lower energy consumption4.Automatic and Continuous Operation5.Flexible production6.Higher quality oil and cake & Steady oil yield7.Perfect Construction, Simple Control and Durable service

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-230 | Vertical | 35-55kg/h | 900×850×1550 |

| 6YY-260 | Vertical | 45-70kg/h | 1050*950*1650 |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are a professional manufacturer and exporter of mechanical equipment. Our products include edible oil process machines.Our well-equipped facilities,complete after-sale service system and excellent quality control system on all stages of production enable us to satisfy customers from different countries. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Service

1.Quality warranty period is two years (except the wearing parts).Equipment must be 100% brand new when leaving factory. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. 2. Whole lifetime maintenance free of charges. 3. Free training course at our plant. 4.Free technical support online or by phone communications&emails.5.Our engineer can be assigned to your country for testing and training as per your requirement.

FAQ

1.Q: How about the after service?A: We have a strong team, special for after service. We can arrange engineers to do service for you. And we insist “Quality is Life”.2.Q: Are you factory or trading company? Where is your factory located?A: We are a factory in machine development; Our factory is located in Zhengzhou Henan Province, welcome you come to China and have a visit.3.Q: Do you have English install step or vedio ?A: Sure, we have.Will send it to you when you need it.4.Q: How does your factory do regarding quality control?A: Quality is priority. We always attach great importance to quality controlling from the beginning.5.Q: why choose Our Machinery?A: We are one of leader in this field(in China). Our quality products and servicehave enabled us to expand our market from china to more than 60 countries.6. Q: How long will you send the machine after I pay?A: Normally, about 5-7 days. Also, if urgent, pls contact with us.7. Q: How can I pay?A: By T/T(wire transfer),Western Union, Money Gram, Alibaba Trade Assurance.Pls feel free to contact us if you want get more information or any question ! !