Applicable Industries:Manufacturing Plant, Retail

Showroom Location:None

Condition:New

Application:Chemical

Packaging Type:CANS

Packaging Material:Wood

Automatic Grade:Automatic

Driven Type:Pneumatic;ELECTRIC, Pneumatic and electric

Voltage:380V/220V

Place of Origin:Guangdong, China

Brand Name:AILE

Dimension(L*W*H):20000*2500*2000

Weight:2000 KG

Warranty:1 Year

Key Selling Points:Energy saving

Machinery Capacity:2400-3600 CANS/H

Filling Material:Water, Oil

Filling Accuracy:99.9%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pump, PLC

Product name:aerosol filling machine

Filling material:Gas and Liquid

Function:filling crimping inflating

Material:Stainless Steel 304

Filling volume:30-750ml

Filling speed:2400-3600 cans/h

Control:PLC+ Touch Screen

Advantage:Explosion-proof

Feature:Quick Changeover

High speed Automatic Christmas snow spray party spray aerosol filling making machine production line

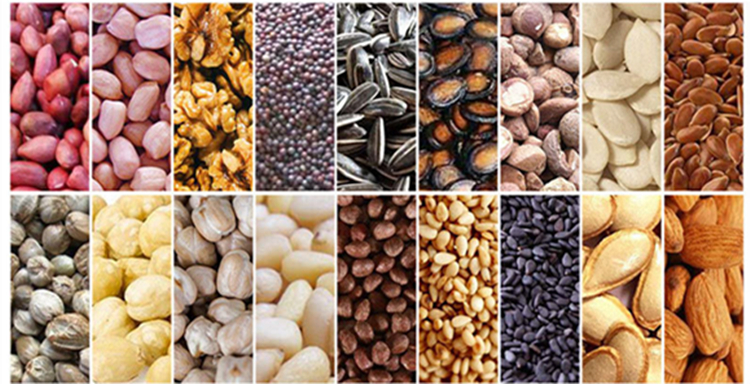

various materials: sesame, walnut, chestnut, cashew, pine nuts, baobab seed, cocoa butter, Argan nuts, avocados, olives, grape seeds, camellia seeds, prickly pear seeds etc.

Raw material

various materials: sesame, walnut, chestnut, cashew, pine nuts, baobab seed, cocoa butter, Argan nuts, avocados, olives, grape seeds, camellia seeds, prickly pear seeds etc.

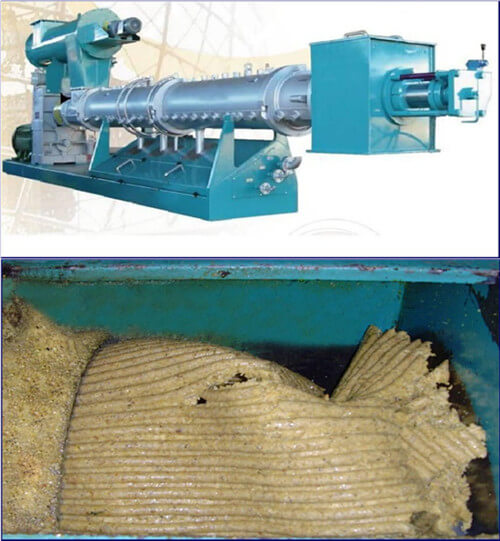

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

Centrifugalization is a kind of method using centrifugal force to separate suspended impurities. Through the drum high-speed rotation of the centrifugal force separate the impurities form oil to reach solid and liquid separation. When the drum stops rotating, and net oil flow from the drum to achieve the purpose of filtering . The filtered oil can do edible test , no foam, no overflowed.

Product Specification

Product Specification

| Usage | sunflower oil production line |

| Type | Cold & Hot Pressing Machine |

| Automatic Grade | Automatic |

| Place of Origin | China |

| Voltage | 220V/380V/440V |

| Oil type | Sunflower Seed Oil |

| Max Capacity | 3000tpd |

| Product name | Vegetable Oil Sunflower Cooking Oil Production Line Of Edible Oil |

| Raw material | Sunflower seeds |

| Factory visit | welcome |

Company Profile

Our company have different machine suitable for all kinds of oil seeds, eg: sunflower seed, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Service

Ensure the quality100% test before delivery All products undergo strict product quality testing before packing.Customized serviceWe are an industry and trade integrated company, has its own production workshop has its own research team. Provide personalizedcustomization service.Rich experienceMore than 30 years independent research and development, independent production experience. Excellent customer service andtechnical support.

FAQ

Q: How long is the smart oil press working once, how much material can be squeezed at one time?A: The working time is not limited.Q: Can the oil press be hot pressed and cold pressed? What is hot pressing? What is cold pressing?A: Yes. The hot press oil rate is higher than the cold press, but the nutritional value is not as healthy as cold pressed oil. Hot pressing is the fryed and heated material. The cold press is that the raw material is not heated before being put into the machine. The direct press of the oil press is cold pressing.Q: How much oil can the smart oil press press at one time? What is the oil yield?Answer: According to the material and operation mode, the different operation modes of different materials have different effects.Q: Can the oil press machine mixes and squeezes oil?A: Yes.Q: What kind of material is the squeezer made of? What material is the external ?A: The squeezed press bar is made of food grade 304 stainless steel, which has high strength and good wear resistance. It does not produce chemical reaction when pressed. The exterior is made of stainless steel, resistant to high temperatures, dirt and easy to clean.