Showroom Location:None

Condition:New

Usage:Various oils

Place of Origin:Henan, China

Brand Name:YINGDA

Dimension(L*W*H):3340*2100*2160mm

Weight:3120 KG

Warranty:1 Year

Key Selling Points:Automatic

Marketing Type:Other

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Other

Oil type:Tea Seed Oil, SESAME OIL, Almond Oil, Coconut Oil, OLIVE OIL, Palm Oil

Max Capacity:800 kg/h

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Video technical support, Online support,attrValueId:190000884

Hot sale 1-100T/D factory price oil press refiner production line

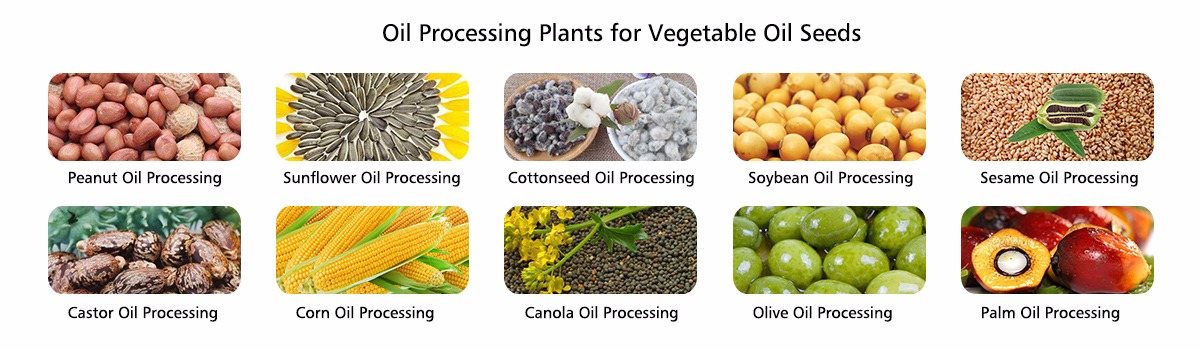

Automatic Cold Pressed Oil Extraction Castor Walnut Press Palm Refining Groundnut Peanut Oil Making Oil Expeller Machine is Suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame, sesame seed, tea seed, walnut, olive, corn germ, rice bran, tea seed, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

The Oil press is used to get the edible oil or bio-diesel from vegetable oilseed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, seasame seed, cottonseed, coconut,, etc

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1.304/316 SUS 2.Customized crude oil refining line capacity. We customize plant as per your requirement for the capacity.3. Flexible usage. The crude oil refining line can work independently or together with whole oil production line.4. Two sets centrifugal machine make sure all continuous production , degumming result is very good.5.The refined oil has high quality and is good for long time storage.6. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

Company Profile

We are a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.1. More than 30 years of experienceThe factory is located in Henan Province, China. We are very welcome to visit our factory. If you need it, we will arrange a pick-up.2.Top production teamThe transportation and packaging will be packaged in international standards. If you have special packaging requirements, we will give you the most suitable solution. 3.High quality productsOur sales manager will send you a production progress picture or video every day, so that you can know the production progress of the product in real time, and we accept L/C payment.

Service

Service before sale1.24 hours online.Your inquiry will be quickly replied by email.Also all questions with you can be sloved by any online chatting tools.2.Professionally and patiently introduction, details pictures and working video to show machine.Service on sale1.Installation:quality and quantity guaranteed;completion of hand over.2.Acceptance: acceptance test;accepted deliverables.3.Technical tranining:on-site installation and products training.Service after sale1.Technical service:long time technical service.2.Accessories supplying:supplying spare parts with cost price.3.Client review:call-back;regular return visit.4.24 hours online to solve any problem .

FAQ

1.Ask:What is this Automatic oil press machine application?Answer:suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame, sesame seed, tea seed, walnut, olive, corn germ, rice bran, tea seed, safflower seed, seeds of hippophae rhamnoides, neem seed, rubber seed, pepper seeds, tomato seeds, watermelon seeds, grape seeds, flax seed, evening primrose, pepper seeds, Castor seeds, Citrus Seeds, beans, beans, almonds, Coffee perilla, peach, rose fruit oil plants.2.Ask:The features of this automatic oil press machine?Answer:Oil Press Machine temperature control, vacuum filtration, three squeeze, high oil, pure color and so on.