Showroom Location:None

Condition:New

Automatic Grade:Semi-automatic

Place of Origin:Zhejiang, China

Brand Name:B&L

Voltage:110-480V

Power:0.55-1.1

Weight:50-500kgs

Dimension(L*W*H):460*860*900, as per need

Warranty:1 Year, 1 years

Fineness:0.8um

Material:stainless steel 304 or 316

Flow rate:0.8-6T/h

Type:filter equipment

technical parameter:20 years manufacture experience

Filter layer:Customized

Processing Types:Alcohol

After Warranty Service:Online support

Local Service Location:None

After-sales Service Provided:Online support

Certification:CE,ISO

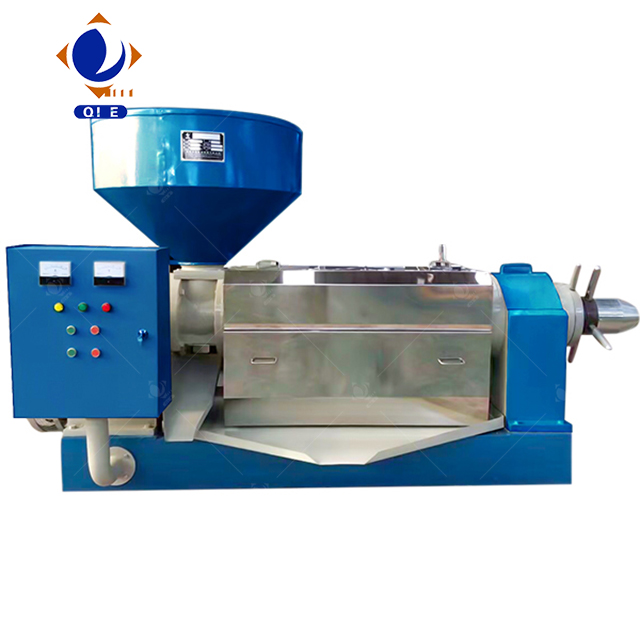

Industrial oil stainless steel filter press machine

Automatic oil machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

Screw press is suitable for pressing rapeseed, peanut kernel, soybean, olive, walnut kernel, corn germ, rice bran, tea seed, safflower seed, sea buckthorn seed, neem seed, rubber seed, pepper seed, tomato seed, watermelon Vegetable oils such as seeds, grape seeds, flaxseed, evening primrose, pepper seeds, castor beans, citrus seeds, cocoa beans, coffee beans, perilla, almonds, peach kernels, and rose hips.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

1,Innovative designs to meet various pretreatment and pressing of multiple oil seeds. Oil seed pretreatment and pressing equipments adopt advanced process design, being equipped with different process on basis of oil seed property. 2,Affordable oil processing solution with low cost. Gashili Food & Oil Machinery provides reasonable designed oil pretreatment and pressing machines with durable structure, low production cost and affordable invest on major oil equipment.3,Environmental protection and energy saving oil plant. Combing the consideration of local climate and water quality with oil pretreatment and pressing process, Gashili assures the most reliable and lowest cost oil machine designs for users worldwide. 4,Full set of production line and services. Gashili promises complete set of oil seed pretreatment & pressing machine production line including design, manufacturing and installation as well as on time after sale service.

Product Specification

Product Specification

| Made in china seeds oil press machines/cottonseed oil expellerSpecification : | ||||

| Model | Capacity ( t/day) | Power(KW) | Outside Size(mm) | Weight(kg) |

| AST-80A | 2.5~3 | 5.5 | 1760*1050*1850 | 600 |

| AST-95CA | 3~5 | 7.5 | 2050*1050*1850 | 940 |

| AST-100A | 3~5 | 7.5 | 2050*1050*1850 | 940 |

| AST-120A | 4~7 | 11 | 2220*1050*1850 | 1200 |

| AST-120CA | 6~8 | 15 | 2340*1050*1850 | 1300 |

| AST-130A | 9~12 | 18.5 | 2450*1100*1950 | 1500 |

| AST-165A | 15~20 | 22 | 2600*1200*1950 | 1680 |

Company Profile

We are a large scale oil machinery manufacturer integrating research, development, design, manufacture and installation. Established in 1982, we have 210 senior engineering technicians among 580 staff, with investment amount of USD60,000.000, covering 10 hectares of factory area, 8 production workshops, 2 machining workshops,12 installation departments.We have 202 sets of automatic processing equipment, annual processing capacity is more than 3000 sets.Our oil machines sell well in more than 30 provinces, cities and districts, and exported to Kazakhstan, Tajikistan, Uzbekistan, Russia, Bolivia, Peru, Egypt, Bangladesh, Myanmar, Malaysia, Indonesia,Solomon Islands, Sudan, Rwanda and other countries and regions, and now we have developed into a major oil machinery manufacturing base in China.

Service

1.Fast DeliveryWe are factory direct sale; we produce and export machine directly2.Competitive priceDirect raw material+cheaper labor= our competitive price3.On-time shipmentCredit&Quality is first! Machine is ready for our own sea/air shipping.4.Quality inspectionOwn advanced manufacturing equipments andcomputercontrolled making machine, so our factory implementassembly line entirely.5.QCStrict quality control system to guarantee 100% high quality.6.SincerityCooperation=whole life friendship. Not only the machine, but our Credit!

FAQ

Q1:WHY BUY FROM US?1) As a real manufacturer, we can supply the best quality machines with reasonable price.2) All the machines pictures and features are real, captured by us, NO Cheating, NO Fraud.3) We are able to get the exactly products for you since we know these machines very well4) We can supply the parts and service in long future.Q2: ARE YOU A NEW MANUFACTURER?A2:We are a major oil press manufacture with a long history in China, in the past decades, we’re focused on domestic market and exporters. Q3: DO YOU HAVE OTHER PRODUCTS ?A3: Yes, we do have a lot of products over than this sit, please feel free to ask us any questions about our products.