Showroom Location:Egypt, Canada, Turkey, Italy, France, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Spain, Thailand, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia, Morocco

Condition:New

Usage:SUNFLOWER OIL

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:80-150Kg/h

Place of Origin:Henan, China

Brand Name:QIE

Voltage:220V/380V/440V

Dimension(L*W*H):1700*1300*1750mm

Weight:3000 KG, 30tons

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

Oil type:Soybean Oil, Basil oil, SESAME OIL, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

Max Capacity:750 kg/h

Advantage:Energy Saving Low Residual

Material:steel,carbon steel

residual oil in meal:less than 1%

Acid value:less than 1.0mg koh/g

Function:crude oil refinery to edible oil

Dimension(L*W*H)::1700*1300*1750mm

indine value:44-46 gl/ 100g

Raw material:crude vegetable oil

Keywords:sunflower oil refining machine

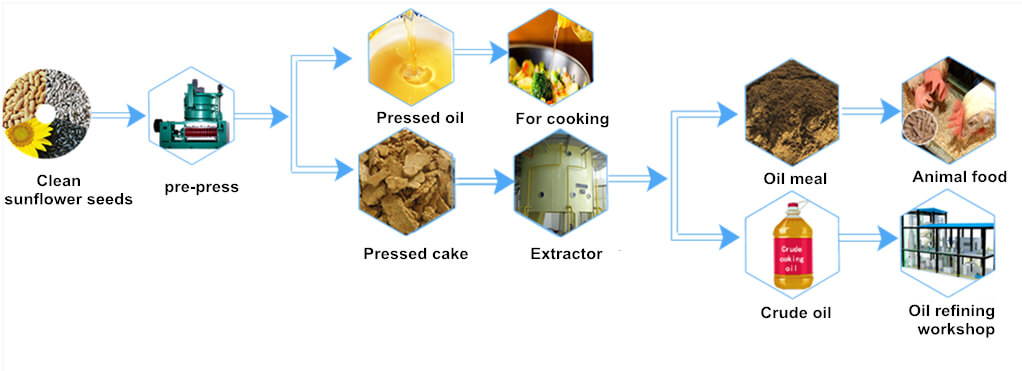

Industrial sunflower cooking oil refining line and automatic refined sunflower cooking oil machine price

soybeans, perilla seed, shelled hemp, flax seed, flax seed,camellia seed, walnut, black sesame, rapeseed, sesame, sunflower seed.Sunflower seeds, almonds, red / white pepper seeds, peanut, pumpkin seeds, pine nut, coconut meat.

Raw material

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Working priciple

Working priciple

The technology flow of cooking oil solvent extraction machine:The process is like oil extracted – wet meal desolvation – mixed oil vaporation – stripping by steam – solvent recoveryMaterial embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing ↓Mixed oil→Filter→Negative pressure evaporation → Crude oil ↓Solvent recovery

Advantage

With Our core part the outstanding press chamber and special feeding and transmitting power systems,we realize the advanced multistage press and gradual pushing compress technology, which add more pressure points and strengthen higher press degree of the materials. Our reasonable and unique design of the inner chamber, more advanced compared with the traditional, for example, the cold press machine is main bar Exhaust type leakage design out of the press chamber , but the hot press machine is main the round Exhaust type leakage design. The other difference between the hot and cold press is the feeding and transmitting system, our super design;

Product Specification

Product Specification

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 |

| Speed of press screw(r/min) | 30-40 | 30-40 | 30-40 | 28-40 | 28-40 |

| Boundary dimension(mm) | 1650*1150*1750 | 900*1300*1850 | 2200*1650*2100 | 2300*1600*2100 | 2400*1700*2100 |

| Capacity(kg/h) | 80-150 | 150-250 | 200-300 | 300-400 | 400-600 |

| Heater(kw) | 2 | 3 | 3.3 | 3.8 | 4 |

| Residual oil rate | 6-7% | 6-7% | 6-7% | 6-7% | 6-7% |

| Weight(kg) | 680 | 870 | 1280 | 1420 | 1600 |

| Power(KW) | 5.5 | 7.5 | 11 | 15 | 380V, 18.5 KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW |

| Product condition | 1 Staff ,plant 20-30㎡ | 1-2 Staff ,plant 30-50㎡ | 2 Staff , plant 40-50㎡ |

2-3 Staff ,plant 40-60㎡ | 2-3 Staff ,plant 60-80㎡ |

Company Profile

We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you!

Service

1. One year quality warranty for the machine and spare parts2. Overseas engineers service for installation3. Whole-life after-sales service and free consultation4. Customized requirements available5. Technician guide at the site.6. 24Hr online service

FAQ

1.Q:Can you guarantee the quality of your machine?A:We are a professional manufacturer with strict quality requirementsoil press machine2.Q:Does your factory accept customization?A:As a professional manufacturer, we can do almost any kind of customization.3.Q:What’s the delivery time?A:Generally after paying the final payment 3-5 days.4.Q:How long can I receive the goods after placing the order?A:7-15 days if there is no unexpected.5.Q:What should I do if the oil making machine will not be installed?A:Don’t worry, we have a perfect after-sales service system and can provide you video supports for free.6.Q:What’s your terms of payment?A:50% in advance, balance before shipment.