Applicable Industries:Food Shop

Showroom Location:None

Condition:New

Application:Chemical, Commodity, Food, filling capping machine

Packaging Type:Cartons, Bottles, case

Packaging Material:Plastic, Wood

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V

Place of Origin:Jiangsu, China

Brand Name:JB

Dimension(L*W*H):6500x1500x1800(mm)

Weight:1200 KG

Warranty:1 Year, 1-2 years

Key Selling Points:High Productivity

Machinery Capacity:4000BPH

Filling Material:Other

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, PLC

Product name:body shop butter filling machine

volume:20-200ml

Capacity:20-50 bottles/min

Control system:PLC

Filling nozzle number:4

Capping head number:1

Function:filling, adding spray pump, capping

Language:English & Chinese

operate pannel:color touch screen

JB-PX4 automatic body shop butter filling machine body oil filling line

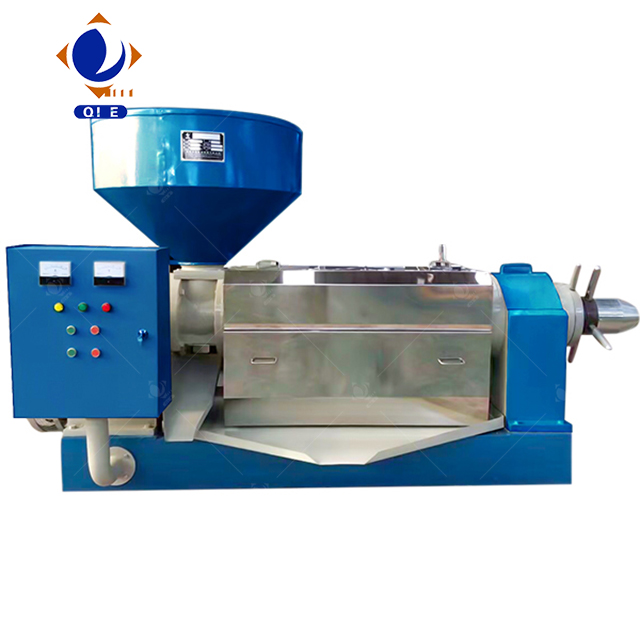

rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

1.Large processing capacity2.Combined Steaming & Cooking3.Lower energy consumption4.Automatic and Continuous Operation5.Flexible production6.Higher quality oil and cake & Steady oil yield7.Perfect Construction, Simple Control and Durable service

Product Specification

Product Specification

| Model | Capacity | oil content in cake | Motor power(kw) |

| 202 | 40-50 TPD | less than 13% | 30 |

| 204 | 75-80TPD | 15-18% | 30 |

| LYZX24 | 20-25TPD | 10-19% | 30+5.5+3 |

| LYZX28 | 40-60TPD | 15-19% | 45+11+1.5 |

| LYZX32 | 80-100TPD | 15-19% | 90+.5+1.5 |

| LYZX34 | 150-180TPD | 11-15% | 160 |

| SYZX12 | 4-6TPD | 4-6.5% | 18.5+1.1 |

| SYZX24 | Hot pressing 80-100 TPD | 10-17% | 55+7.5 |

| Cold pressing 40-50 TPD | 5-7% |

Company Profile

Since 1982 oil press machine1. More than 20 years of foreign trade export experience.2. The professional design R&D team, backed by the university and guided by the market to updated the products.3. Our products exported to the United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Bulgaria and other countries and regions, and got very good reputation.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

Q: How long is the smart oil press working once, how much material can be squeezed at one time?A: The working time is not limited.Q: Can the oil press be hot pressed and cold pressed? What is hot pressing? What is cold pressing?A: Yes. The hot press oil rate is higher than the cold press, but the nutritional value is not as healthy as cold pressed oil. Hot pressing is the fryed and heated material. The cold press is that the raw material is not heated before being put into the machine. The direct press of the oil press is cold pressing.Q: How much oil can the smart oil press press at one time? What is the oil yield?Answer: According to the material and operation mode, the different operation modes of different materials have different effects.Q: Can the oil press machine mixes and squeezes oil?A: Yes.Q: What kind of material is the squeezer made of? What material is the external ?A: The squeezed press bar is made of food grade 304 stainless steel, which has high strength and good wear resistance. It does not produce chemical reaction when pressed. The exterior is made of stainless steel, resistant to high temperatures, dirt and easy to clean.