Showroom Location:None

Condition:New

Usage:oil extraction machine

Type:Citrus oil milling machine

Automatic Grade:Automatic

Production Capacity:High

Place of Origin:Henan, China

Brand Name:Leading Machinery

Voltage:380V

Dimension(L*W*H):3650*1100*1500mm

Weight:970 KG

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pump, Bearing

Oil type:Fruit oil grinder

Max Capacity:10t/h

Raw material:Citrus, orange, lemon, pomelo

Name:Citrus Oil Mill Machine

Function:Orange Oil Mill Machine

Application:Citrus Oil Extraction

Advantage:High Efficient

Material:304 Stainless Steel

Capacity:300-500kg/h

Item:oil milling machine

Color:Silver

Product name:Large Capacity Automatic Citrus Oil Mill Machine

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Free spare parts, Field maintenance and repair service, Online support

Certification:ISO9001

Large Capacity Automatic Citrus Oil Mill Milling Machine

It can be used for various materials such as Peanuts, Rapeseeds, Sesame seeds, Soybeans, Cottonseeds, Tea seeds, Sunflower seeds, Palm kernel etc.

Raw material

Processing materials: sunflower seed, peanut, mustard, almond, black sesame, tea seed, cottonseed, etc

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-230 | Vertical | 35-55kg/h | 900×850×1550 |

| 6YY-260 | Vertical | 45-70kg/h | 1050*950*1650 |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

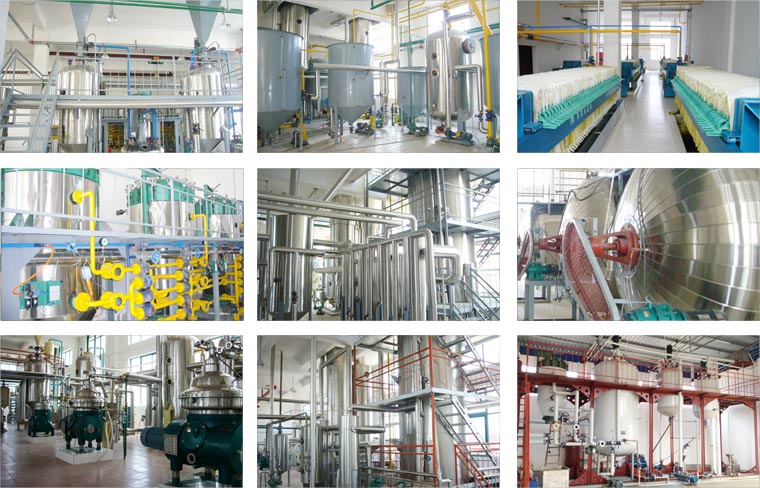

We are a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.1. More than 30 years of experienceThe factory is located in Henan Province, China. We are very welcome to visit our factory. If you need it, we will arrange a pick-up.2.Top production teamThe transportation and packaging will be packaged in international standards. If you have special packaging requirements, we will give you the most suitable solution. 3.High quality productsOur sales manager will send you a production progress picture or video every day, so that you can know the production progress of the product in real time, and we accept L/C payment.

Service

1, What kind of transport can be available ?LCL and FCL by ship ,By Express (DHL,TNT, Fedex etc) , By airOr you can use your own shipping agent in China.2,How long will the machine be sent out?We usually delivery in 3-5 working days after getting full payment, and we will inform you shipping time based on your seaport.3, How long is the guarantee?We promise guarantee as one year for non-human damage factor.4, What should we do when have some problems during using?We can supply English manual book and also take a video for showing how to resolve the problems or dispatch our worker to your factory.

FAQ

1.Are you a trading company or a manufacturer?We are a manufacturer.2.How to study to operate this machine?You may View the operation video to study how to operate it.3. If the machine is damaged during use, how to maintain it?Please contact us to obtain the spare parts support.4. What is the price?We offer a price range on the website, If you want to know the exact price, please inform us of the port of destination.5. I’m a stranger to large machines, what should I do?we provide paid services such as the installation, debugging and technical training to customers who buy large machines. Of course, You can also come to our factory for free training.6.How to become a local agent?If you want to be an agent to develop the local market, please contact us.