Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Other

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Machinery & Hardware

Packaging Type:CANS, Bottles, Barrel, Stand-up Pouch, Bags, Cartons, CANS, Bottles, Stand-up Pouch, Bags, Pouch, Capsule

Packaging Material:Plastic, Glass, Other

Automatic Grade:Semi-automatic

Driven Type:Pneumatic

Voltage:220V

Place of Origin:Hebei, China

Brand Name:Shean, SH

Dimension(L*W*H):130X55X40 cm

Weight:35KG

Warranty:1 Year

Key Selling Points:Easy to Operate, Energy saving

Machinery Capacity:400BPH, 500BPH, 1000BPH, 100BPH, 200BPH, Other

Filling Material:Milk, Water, Oil, Juice, Other

Filling Accuracy:±1%

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Pressure vessel, Other, PLC

Nozzle Diameter:1CM

Filling material:Paste or Liquid

Function:Paste Filling

Material:Stainless Steel 304

Usage:Paste Filling Machine

Keywords:Filling Machine

After Warranty Service:Video technical support, Spare parts

Local Service Location:None

After-sales Service Provided:Online support, Field installation, commissioning and training

Low price A02 manual pedal pneumatic liquid/paste beverage sauce filling machine

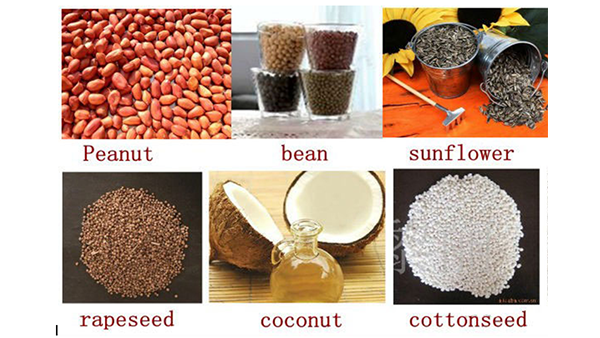

Our Integrated oil press is used widely for processing rapeseeds, cottons, soybeans, peanuts, sesames, sunflowers, tung seeds, olive coconut meat,palm and other granulated oil materials, as well as using for rice bran, corn embryo and powered oil materials and safflower and other wild plant oil materials. It’s regeneration products for medium-small scale plant oil mill in country and private factory,and ideal choice for users to realize well-off life.

Raw material

Oil refining workshop application :Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil all refined oil.

Working priciple

Working priciple

6YL-68 oil making machine is a screw type pressing machine that is capable of extracting oil within a caged barrel-like cavity. Usually, raw material enters it from the feeder. Then, the machine utilizes strong frication and continuous pressure to compress the raw material. After compression, the oil will come out from a small oil outlet. More importantly, the seed fiber solids and other larger impurities can’t pass through the small oil outlet. And, the extracted seeds will be pressed into hardened oil cakeand discharged from your oil making machine.

Advantage

1.304/316 SUS 2.Customized crude oil refining line capacity. We customize plant as per your requirement for the capacity.3. Flexible usage. The crude oil refining line can work independently or together with whole oil production line.4. Two sets centrifugal machine make sure all continuous production , degumming result is very good.5.The refined oil has high quality and is good for long time storage.6. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

Since 1982, our company was found officially registered under Henan Companies Registry. Who is the leader in the oil press equipment field of China. The main products are hydraulic oil press machine, screw oil press machine, the accessory equipment for the oil press machine and other equipments.Our company has a professional design R&D team and sales team, backed by the university and guided by the market to update the products, The products have covered the reigion of China with nearly a million users. Our products had exported to many countries such as United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Algeria, Bulgaria and so on, have received very good reputation.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.

FAQ

a discount.Q8: Do you have machines in stock?Yes, we have some models oil press in stock.Q9: How will my order be packed, can you provide the installation service?Packed in plywood case. We will send English manual. If the customer need, we will send one engineer for assembling and training for workers.