Applicable Industries:Food & Beverage Factory, Other, Cleaning Liquid Industry, Cosmetic Industry, Chemical industry, Pharmaceutical industry

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Chemical, Other

Packaging Type:Strong Wooden Case

Packaging Material:Wood

Automatic Grade:Automatic

Driven Type:Pneumatic

Voltage:220/380V 50/60Hz

Place of Origin:Tianjin, China

Brand Name:MTW

Dimension(L*W*H):2400*900*2200mm

Weight:500 KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:2000-4500BPH

Filling Material:Other, Oil, cosmetic/chemical products

Filling Accuracy:+/-0.5~1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine, Other

Product name:filling capping labeling production line

Material:Stainless Steel 304/316

Factory direct sale:Yes

Filling range:10-6000ml (can be tailor made)

Control:PLC+ Touch Screen

Customizable:Yes

Feature:High speed

Advantage:High efficiency

Local Service Location:None

After Warranty Service:Video technical support,Online support

MTW peanut butter sunflower seeds oil production line bottling fully auto filling capping machine with CE

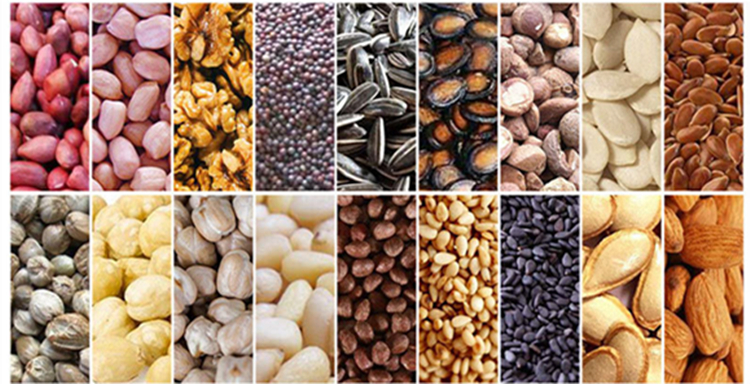

Automatic oil machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

This oil press machine can be used to make cooking oil with raw materials such as flax seed, peanut, rapeseed, sesame,sunflower, etc.

Working priciple

Working priciple

The technology flow of cooking oil solvent extraction machine:The process is like oil extracted – wet meal desolvation – mixed oil vaporation – stripping by steam – solvent recoveryMaterial embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing ↓Mixed oil→Filter→Negative pressure evaporation → Crude oil ↓Solvent recovery

Advantage

Advantages of cooking oil making machineThe whole extraction workshop is selected on the base of safety,reliable,energy-saving, less fault,easy maintenace,and long using life,adopting world advanced technology and equipment to achieve the beat process effects.Features of cooking oil processing machine:Applicable for various kinds of low oil content raw material,like rice bran, rapeseed, cotton, corn germ etc cakes for max oil yield. After extracting ,the resid oil is lower than 1%.

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We are a China manufacturing and project engineering company with a global outlook, specializing in the design, production and supply of quality machines and integrated systems for the Edible Oil Production.

Service

1.12 months warranty ,including core parts;2.Video support and online technical guidancem forever;3.Offer video support and online technical guidence at any time;4.Supply spare parts all the world;5.The worldwide agents have good policies and greatest support.

FAQ

1. Q: Which kind of materials can be process?A: All kinds of oil seeds, including common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-5000 tons per day. 3.Q: How long is your guarantee ?A: One Year guarantee. Supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How is the quality of your products ?A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.