Applicable Industries:Hotels, Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Advertising Company

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Medical, Chemical, liquild filling

Packaging Type:Bottles, Stand-up Pouch, Bags, Pouch, cream&shampoo&

Packaging Material:Plastic, Glass

Automatic Grade:Semi-automatic

Driven Type:Manual, Manual

Voltage:0

Place of Origin:Jiangsu, China

Brand Name:BRENU

Dimension(L*W*H):34*34*78CM

Weight:13KGS

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:Other, 2000BPH, 1000BPH, 200BPH

Filling Material:Beer, Other, Milk, Water, Oil, Juice

Filling Accuracy:± 1%

Marketing Type:Other

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Engine

Product name:filling machine

Key word:softgel encapsulation filling machine

Filling Range:5-50ml

Capacity of Hopper:22lbs/10kg

Filling accuracy:±1%

Filling speed:20-40times/min( also depend on operation speed of stuff)

Filling Bottle diameter range:3-15 mm

Filling material:cream & shampoo,Cosmetic etc

Working head:Single head

After Warranty Service:Video technical support, Online support

Local Service Location:other

After-sales Service Provided:Online support

Certification:CE ISO

New Design Softgel Encapsulation Filling Machine Made In China

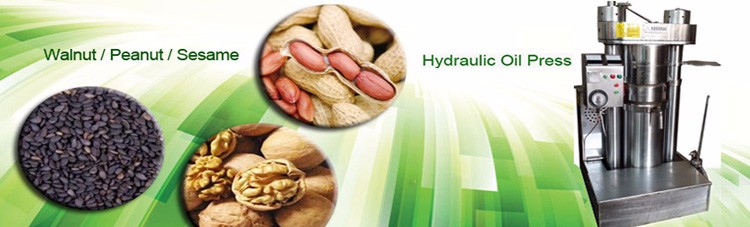

the plant is suitable for Soybeans, peanuts, corn, flax, linseed, tea seed(camellia seed), sesame,walnuts, rapeseed, grape seed,castor, sunflower, cottonseed etc.

Raw material

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Working priciple

Working priciple

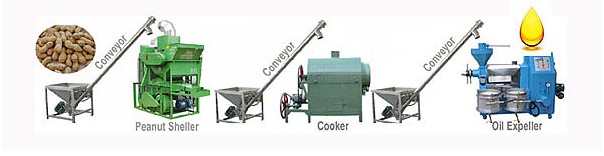

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantage

6YL68 Screw Oil Press Machine characterized by its simple design, small volume and lightweight, easy to handle and move.This machine is able to extract oil from various of vegetable oil materials, the machine can be used for cold pressing as well as hot pressing, highly productive, easy for operating ,low labor intensity and high economical profit ,which also has less noise and a high rate of oil output, hence, it is welcome by customers.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you!

Service

1.We are a factory manufacturing edible oil machine, best production capability, best quality control, best Service.2.100% quality control inspection for every machine.3. Competitve price.

FAQ

Q1:WHY BUY FROM US?1) As a real manufacturer, we can supply the best quality machines with reasonable price.2) All the machines pictures and features are real, captured by us, NO Cheating, NO Fraud.3) We are able to get the exactly products for you since we know these machines very well4) We can supply the parts and service in long future.Q2: ARE YOU A NEW MANUFACTURER?A2:We are a major oil press manufacture with a long history in China, in the past decades, we’re focused on domestic market and exporters. Q3: DO YOU HAVE OTHER PRODUCTS ?A3: Yes, please feel free to ask us any questions about our products.