Applicable Industries:Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use

Showroom Location:None

Condition:New

Application:Food, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes

Packaging Type:Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Bags, Other

Packaging Material:Plastic, Glass, Other

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V/50 60HZ

Place of Origin:Shandong, China

Dimension(L*W*H):/

Weight:1000 KG

Warranty:1 Year, 12 Months

Key Selling Points:Automatic

Machinery Capacity:2000BPH, 1000BPH, Other

Filling Material:Milk, Water, Oil, Juice

Filling Accuracy:0.1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:PLC, Motor, Pump, Gear, Bearing, Other

Product name:Automatic weighing filling machine line

Function:Automatic Filler

Usage:Liquid Oil Paint Packaging

use:Paint,edible oil,cooking oil,lubricant oil,motor oil,Vehicle urea

Filling volume:10-20kg

Control:PLC+ Touch Screen

Model:2-12 nozzles

Packing speed:500-3000 bottles per hour

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE/ISO

New Style High Quality Industry Multi-purpose Quantitative Lpg Filling Weighing Machine

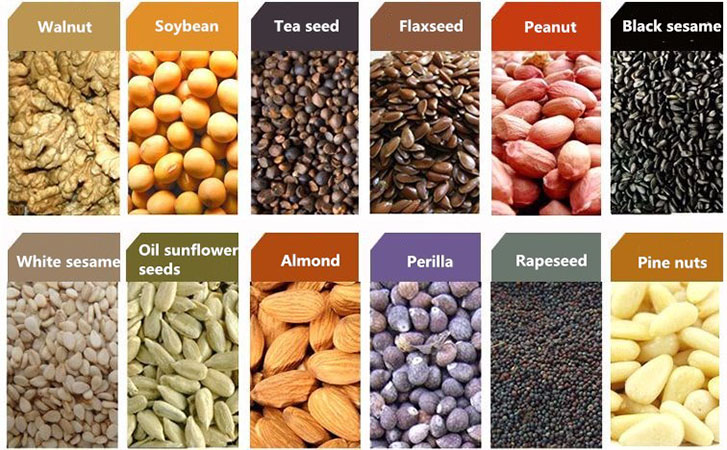

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Raw material

The oil production line is widely used in the production for various vegetable oils from the raw material to the final oil in the market. It is very popular for the production for edible oil and vegetable oils, such as sunflower oil, peanut oil, soybean oil,sesame oil, corn oil, palm oil, olive oil, castor oil, cottonseed oil, etc.

Working priciple

Working priciple

Crude seeds→ cleaning → softening → expanding → drying → to extraction workshop; Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect.

Advantage

small business flaxseed sesame oil press groundnut processing oil machine adopt newest technology. Its advantage:1. Easy to operate.2. High oil yield.3. Extensive use.

Product Specification

Product Specification

| Model | 6JY-60 | 6JY-70 | 6JY-80 | 6JY-100 | 6JY-125 | 6JY-150 |

| Squeeze spiral Diameter | 55mm | 63mm | 80mm | 100mm | 125mm | 150mm |

| Squeeze screw speed | 64r/min | 63r/min | 63r/min | 43rmin | 36rmin | 36r/min |

| Power | 2.2kw | 3kw | 5.5kw | 7.5kw | 11kw | 15kw |

| Heating power | 0.9kw | 1.5kw | 3kw | 3.5kw | 4kw | 4kw |

| Capacity | 30-60kg/h | 60-90kg/h | 80-130kg/h | 200-260kg/h | 300-350kg/h | 450-500kg/h |

| weight | 230kg | 280kg | 565kg | 760kg | 920kg | 1200kg |

| size(LWH) | 1200*800*1160 | 1400*950*1250 | 1650*1500*1600 | 2000*1500*1720 | 2100*1500*1750 | 1600*2100*1720 |

| Voltage | 220v | 220v | 380v | 380v | 380v | 380v |

| Model | Capacity(t)/Day | Power(KW) | Material | Loading size(container) | Process range |

| YHJ-03 | 1.8T | 30.95KW | SUS304/316 | 20GP | 1-4 Grade |

| YHJ-05 | 3T | 37.45KW | SUS304/316 | 20GP | 1-4 Grade |

| YHJ-10 | 6T | 46KW | SUS304/316 | 40HQ | 1-4 Grade |

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

Our company is a large-scale modern manufacturing company specialized in the R&D, manufacturing and sales of food oil processing machinery, which covers an area of 18,000 square meters. Numerous plants are installed in Netherlands, Kazakhstan, Malaysia, Nigeria, Nepal, Bangladesh, Sri Lanka, Indonesia, Bulgaria, New Zealand, Peru, South Africa, and Saudi Arabia, etc..We have our own showroom to showcase our products.You can meet all products there.Welcome to Company.

Service

Pre-sale services:Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment(1) Select equipment model;(2) Design and manufacture products according to clients’ special requirement;(3) Train technical personnel for clients.After-sale services:(1) Assist clients to prepare for first construction scheme;(2) Install and debug the equipment;(3) Examine the equipment regularly;(4)Take initiative to eliminate the troubles rapidly at site;(5)Provide technical exchanging;(6)Provide maintenance for big items

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.