Max.Bottle Height(mm):240 mm

Neck Diameter(mm):38 mm

Max.Bottle Diameter(mm):69 mm

Bottle Volume(ml):750 ml

Condition:New

Application:bottle

Blow Moulding Type:Stretch Blow Moulding

Place of Origin:Zhejiang, China

Brand Name:WATON

Voltage:Customized

Dimension(L*W*H):580*210*240 cm

High Pressure Valve Brand:AirTac

Rotary Cylinder Brand:SMC

PLC Brand:Schneider

Power (kW):55

Weight (KG):7500 KG

Automation:Automatic

Warranty:1 Year

Key Selling Points:Competitive Price

Showroom Location:Peru, Saudi Arabia, Spain, Turkey, France, Russia, Italy, Thailand, Mexico, India, Pakistan, Viet Nam, Canada, United States, Brazil, United Kingdom, Indonesia, Germany, Egypt, Philippines, South Korea, Algeria, Chile, UAE, Japan, Uzbekistan, Nigeria, Argentina, Romania, Australia, Ukraine, Kyrgyzstan, Malaysia, Tajikistan, Bangladesh, Kenya, South Africa, Colombia, Morocco, Sri Lanka

Applicable Industries:Food & Beverage Factory

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Bearing, Motor, Pump, Gear, PLC, Other, Pressure vessel, Engine, Gearbox

Model Number:MS-2L4

Suitable bottle:Water bottle/juice bottle/drink bottle/oil bottle

Advantages:Compact, saving energy, fast, easy maintenance.

Machine capacity:1400-2000 BPH

Bottle capacity:50~2000 ML

Mold cavity:4

Bottle Max Diameter:69mm

Bottle Max Height:240mm

OEM/ODM service:Yes

Type:Semi-automatic

PET Preform Blowing Machine With Auto Loader Four Cavities Hot Semi-Automatic Blow Molding Machine

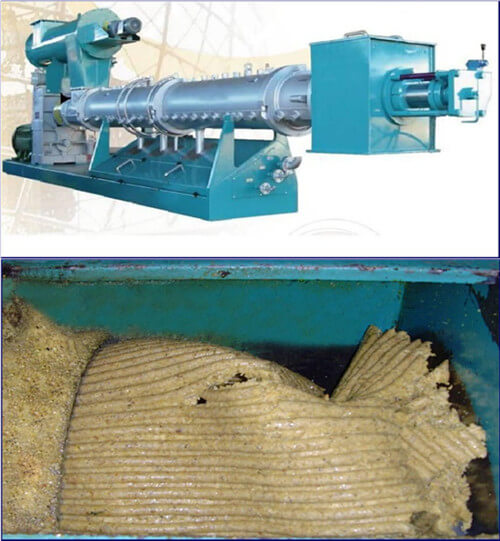

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

Raw material

All kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Working priciple

Working priciple

Capacity: 35-50t/d (according to cottonseed)Prepress:100-150t/dResidual oil content in cake:10%-16%Motor powder: main engine 75KW, cooker 5.5KW, feeder 2.2KWNet weight:approx 8500KgDimension:3800*1240*3420mmCake thickness:8-20mmMotor current:120A-130AScrew spindle speed:32rpm or 38rpm

Advantage

1,Innovative designs to meet various pretreatment and pressing of multiple oil seeds. Oil seed pretreatment and pressing equipments adopt advanced process design, being equipped with different process on basis of oil seed property. 2,Affordable oil processing solution with low cost. Gashili Food & Oil Machinery provides reasonable designed oil pretreatment and pressing machines with durable structure, low production cost and affordable invest on major oil equipment.3,Environmental protection and energy saving oil plant. Combing the consideration of local climate and water quality with oil pretreatment and pressing process, Gashili assures the most reliable and lowest cost oil machine designs for users worldwide. 4,Full set of production line and services. Gashili promises complete set of oil seed pretreatment & pressing machine production line including design, manufacturing and installation as well as on time after sale service.

Product Specification

Product Specification

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 | 6YL-160 |

| Screw speed | 30-45r/min | 30-40 r/min | 30-40 r/min | 28-40 r/min | 28-40 r/min |

| Gear Ratio | 14/42×19/57=1:6.63 | 15/40×15/55=1:9.78 | 15/34×15/55=1:9.59 | 15/38×19/48=1:7.38 | 15/38×15/52=1:8.78 |

| Dimension | 1700*1300*1750mm | 2100*1360*1950mm | 2050x1350x2000mm | 2400x2300x1700mm | 2500x1600x2500mm |

| Productivity | 80-150kg/h | 150-250kg/h | 200-300kg/h | 250-400kg/h | 450-600kg/h |

| Power | 6-5.5KW | 6-7.5KW | 6-11KW | 6-15KW | 6-18.5KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW | Y100L1-4-2.2KW |

| Heater | 2KW | 3KW | 3.3KW | 3.8KW | 4KW |

Company Profile

Our company has been specially engaged in research, develop and manufacture oil press machines. Our main products are Screw Hot Oil Press machine, Screw cold&hot Oil Press machine, automatic Hydraulic Oil press machine,and the auxiliary products such as Material&Cake lifters, enviromental Electric Roller Roaster, peanut Sheller, Tea seed Sheller, Seed Cleaners , edible oil refining equipment, Oil Filters and so on . Our service network has covered the whole country and exported to Southeast Asia, the Middle East, West Africa, Russia abroad.All our parts are made of the high quality 20CrMnTi alloy steel , processed with the imported equipment through the process of cementit quenching and high frequency quenching.So the high hardness parts make our series of oil press machines distinguished in high oil yield and least wearing and tearing.Qi Feng adhere to the “people-oriented, technology innovation” business philosophy, adhere to the “science and technology service for society, quality seek survival, seek development with prestige” business purpose.Our company staffs warmly welcome customers at home and abroad to negotiate further business to pay visits to our factory for live experience!

Service

24 hours on-line service Professional person overseas if you need1 warranty for you (full-life service)First-class after-sale serviceSafe&Fast delivery 1.More than 10 years’ experience in manufacturing food processing machine. 2.Top quality, Reasonable price, Safe and Timely delivery and First-class Service . 3.One year guaranty, life-time technical support, some parts free . 4.Installation Services: Installation Services are available with all new machine purchases. We provide the technical help for installing, debugging, operation to make no further problems! 5.After Sales Service: Our company offer Preventative Maintenance and After Sales Service. We strongly believe it is very important for the long-term development of our company. Consequently we offer comprehensive maintenance options to prevent equipment issues;

FAQ

Q: How long is the smart oil press working once, how much material can be squeezed at one time?A: The working time is not limited.Q: Can the oil press be hot pressed and cold pressed? What is hot pressing? What is cold pressing?A: Yes. The hot press oil rate is higher than the cold press, but the nutritional value is not as healthy as cold pressed oil. Hot pressing is the fryed and heated material. The cold press is that the raw material is not heated before being put into the machine. The direct press of the oil press is cold pressing.Q: How much oil can the smart oil press press at one time? What is the oil yield?Answer: According to the material and operation mode, the different operation modes of different materials have different effects.Q: Can the oil press machine mixes and squeezes oil?A: Yes.Q: What kind of material is the squeezer made of? What material is the external ?A: The squeezed press bar is made of food grade 304 stainless steel, which has high strength and good wear resistance. It does not produce chemical reaction when pressed. The exterior is made of stainless steel, resistant to high temperatures, dirt and easy to clean.