Brand Name:JINPENG

Condition:New

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Equipment Capacity:5-12 tons per day

Warranty:1 Year

Key Selling Points:Competitive Price

Weight (KG):9000 KG

Showroom Location:Spain, Chile

Applicable Industries:Manufacturing Plant, Energy & Mining

Certification:ISO

reactor material:Q245R boiler steel

raw material:tyre, rubber, plastic

thickness:16mm

heating method:direct

Feature:Tire Recycling Production Line

structure:horizontal type

cooling metod:water recycling

Plastic Plant Machine Used Tyre Pyrolysis Oil Equipment Tire Recycling Production Line

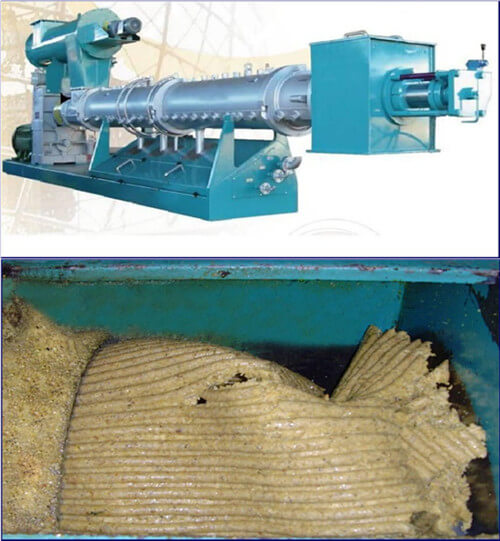

This system screw oil press is small type , which is better for the processing of various kinds of vegetable oil-bearing crops,such as the rapeseed/canola, peanut kernel, soybean,olive,walnut kernel, maize germ, rice bran, teaseed, sallow thron seed, chinaberry seed, rubber seed, china pepper seed, tomato seed, water melon seed, grape seed, flax seed, Oenothera seed, pepper seed, castor seed, orange seed, cocoa bean, coffee bean, perilla,almond kernel,peach seed kernel,etc.

Raw material

Small business flaxseed sesame oil press groundnut processing oil machine is suitable with most raw materials, such as sesame, soybean, coconut, peanut, palm kernel, coffee bean, sunflower seeds, sea buckthorn seeds, moringa seeds, etc.

Working priciple

Working priciple

vegetable oil processing plant/oil extracting machine/oil refinery machinepretreatment/pre-press equipment.

Elevator- shelling – elevator – cleaning -elevator – magnetic drum – flaking- elevator -cooking – pre-press- to extraction work

Advantage

(1)The lubrication should be checked after every 50 hours of operation. The oil cup on the gearbox should not be short of oil. The screw shaft should be adjusted from the adjustment screw hole to the oil in the screw hole. Dry grinding is strictly prohibited.(2)The parts of the oil should be protected from dust and other impurities. The quality of the oil in the gearbox should be checked once a year. If it is found to be deteriorated, all oil should be replaced.(3) When the crushing amount is reduced and the cake or oil is not normal, the screw shaft should be taken out to check the wear of the screw, the strip and the cake ring, and the worn parts should be replaced in time.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-230 | Vertical | 35-55kg/h | 900×850×1550 |

| 6YY-260 | Vertical | 45-70kg/h | 1050*950*1650 |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are one leading producer of oil equipment in China. We are specialized in vegetable oil production line for 40 years. Our company have special engineers for cooking oil making machine. They are reseaching and developing the technology.We have advanced processing vegetable oil production line and scientific management system. The vegetable oil production line have gained many achievements and awards. Our machines have been exported to Congo, Urganda, Uzbekistan, Kazakhstan, Cananda, Chile, Argentina, Ethiopia, Zambia, Nigeria, Russia, Turkey and so on.

Service

Acceptance standardUnless stipulated in the technical documents accordingly, technology acceptance standards of designed main parts are in accordance with relevant state departments issued current relevant standards. providing main parts technology acceptance standard of technical design. Technical serviceDuring rice mill machinery installation, We cooperate with buyer for technological improvement to reach desired results. We explains rice mill machinery performance, structure and operation to buyer related people for free.Quality guaranteed We makes sure our rice mill machinery achieve promised performance with correct installation, commissioning, normal operation and maintenance. In warranty period, for quality problem, we repair and replace defective parts for free(except quick-wear part).

FAQ

Usually the delivery time is 3-15 working days after prepayment received.Q7: What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you