Machine Type:H Frame Hydraulic Press

Ejector Force (kN):24000

Return Force (kN):500 kN

System:Normal

Condition:New

Place of Origin:Jiangsu, China

Brand Name:SBM

Year:2017

Voltage:Customized

Dimension(L*W*H):Machine Size

Weight (T):50 T

Motor Power (kw):55 kw

Key Selling Points:Automatic

Warranty:1 Year

Applicable Industries:Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Printing Shops, Retail, Home Use, Energy & Mining

Showroom Location:None

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Pressure vessel

CNC or Not:CNC

Application:Metal Sheet

Model:Deep drawing press

Function:Steel Metal stamping

Control system:PLC(Touch Screen)

Worktable size:2800x2000mm

Weight:70Ton

Power(W):55Kw

Quality Guarantee 2000 Ton Steel Material Automatic Deep Drawing Hydraulic Oil Press Machine

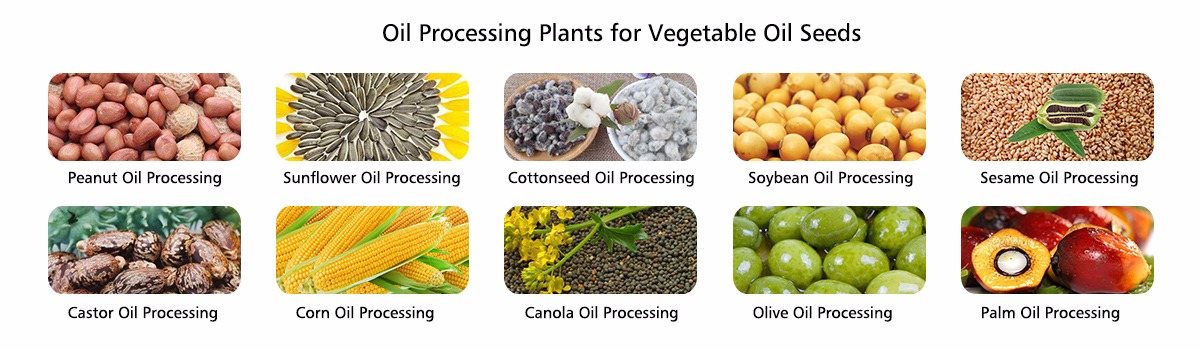

various materials: sesame, walnut, chestnut, cashew, pine nuts, baobab seed, cocoa butter, Argan nuts, avocados, olives, grape seeds, camellia seeds, prickly pear seeds etc.

Raw material

Although 6YL-68 Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Working priciple

Working priciple

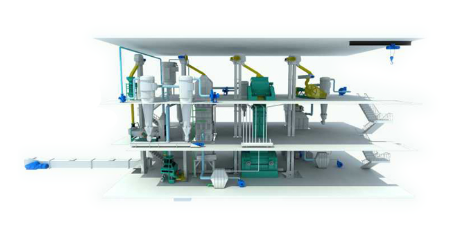

Main Process of cooking oil refinery machine:1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.3. Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Advantage

(1) High oil yield , obvious economic benefit.(2)Residual oil rate in the dry meal is low.(3)Improving the quality of the meal and oil.(4)Low processing cost , high labor productivity.(5)High automatic and labor saving.And more other advantages please contact me now,we will provide profession program for you,and we accept custom according your requirements.

Product Specification

Product Specification

| Model | TZ-60A | TZ-80A | TZ-100A | TZ-125A | TZ-150A |

| Screw diameter | 60mm | 80mm | 100mm | 125mm | 150mm |

| Capacity (kg/h) | 30-60 | 125-150 | 200-250 | 250-350 | 500-600 |

| Motor | 2.2kw | 5.5kw | 7.5kw | 15kw | 22kw |

| weight (kg) | 220 | 700 | 1100 | 1400 | 1700 |

|

Company Profile We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you! Service Pre-sale services:Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment(1) Select equipment model;(2) Design and manufacture products according to clients’ special requirement;(3) Train technical personnel for clients.After-sale services:(1) Assist clients to prepare for first construction scheme;(2) Install and debug the equipment;(3) Examine the equipment regularly;(4)Take initiative to eliminate the troubles rapidly at site;(5)Provide technical exchanging;(6)Provide maintenance for big items FAQ Q1: What does Eternal need from me to quote a price?1.Raw material2.Production capacity per hourQ2: What is the oil yield?The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.The oil residual of our small hydraulic oil press machine, cold press virgin coconut/avocado/olive oil extraction extracting machine is 6%Q3: Can I use the machine to extract several kinds of raw materials?Yes,of course. such as sesame, sunflower seeds, soybean, peanut, coconut, etcQ4: Can I do extraction test with my own raw material?Yes,of course.We can do extraction test and send you videos and test report for your Reference.Q5: What is your material of your machine? |