Applicable Industries:Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant

Showroom Location:Italy, Viet Nam, Peru, Saudi Arabia, Indonesia, Spain, Thailand, Kenya, Argentina, South Korea, UAE, Malaysia, Australia

Condition:New

Application:Food, Beverage

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380v 50hz 3 phase

Place of Origin:China

Brand Name:AQUA

Dimension(L*W*H):2300X1500X 2400

Weight:2200KG

Warranty:2 YEARS

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

Filling Material:Beer, Milk, Water, Oil, Juice

Filling Accuracy:>=99%

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, PLC, Gear, Bearing

name:5 Lines to South America 19Liter 5 Gallon Water Bottle Filling Machine

Bottle Volulme:200-3000ml

Material:Full grade SUS304

Advantage:Automatic /Nobody Guard

Model:QGF

Filling speed:100-2500BPH

Usage:drinking machine / mineral water

Container Required:PC/ PET 5 GALLON

Control:PLC Touch Screen

Packing material:PE film

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Canada, France, Germany, Viet Nam, Saudi Arabia, Indonesia, Spain, Australia, Kenya, Argentina, UAE, Colombia, Algeria

Certification:CE

Ready To ship 5 Lines to South America 19Liter 5 Gallon Water Bottle Filling Machine

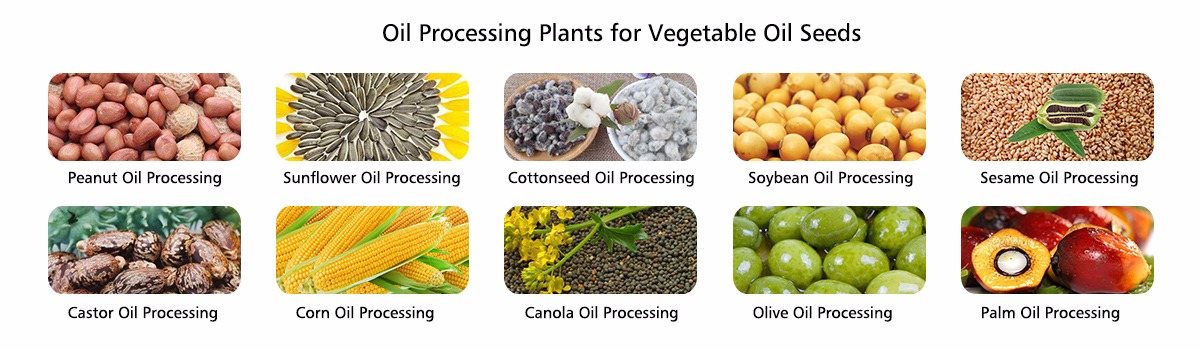

Our Oil Extraction Machine are modern products developed and improved our company newly. Automatic oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Working priciple

Working priciple

Main Parts Of The Automatic Oil Press Machine:1.screw shaft2.feeder3.pressing cage4.oil pan5.squeezing bolt6.vacuum oil filter system7.electric control system8.heating ring

Advantage

1.This type of automatic screw cold oil making press machine equipment is able to do both cold press and hot press.2.Widely-used:the oil press can be used for more than 20 kinds oil crops.3.Pure oil quality:the vacuum oil filtering is used to remove residue so as to ensure the pure oil quality and meet the standard of health quarantine.4.Save space and labor:an area of 10-20 square meters workshop and 1 to 2 worker can meet the need of production.5. Good quality, durable: made of high-quality materials, high temperature resistance, strong wear resistance.High hardness, high strength, no deformation, long service life. 6. Easy to operate: simple structure, easy to use.One person can complete the entireoperation process .7. Factory direct selling, cost-effective: price concessions, more than one machine, one time squeeze net. 8.Mature technology: mature technology, advanced processing equipment and precise internal structure are adopted. 9. Clean, energy efficient, hygienic: The filtered oil can be used directly and the extracted oil is beautiful.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Service

6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service (paid)5. VIP price for the coming order.

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.